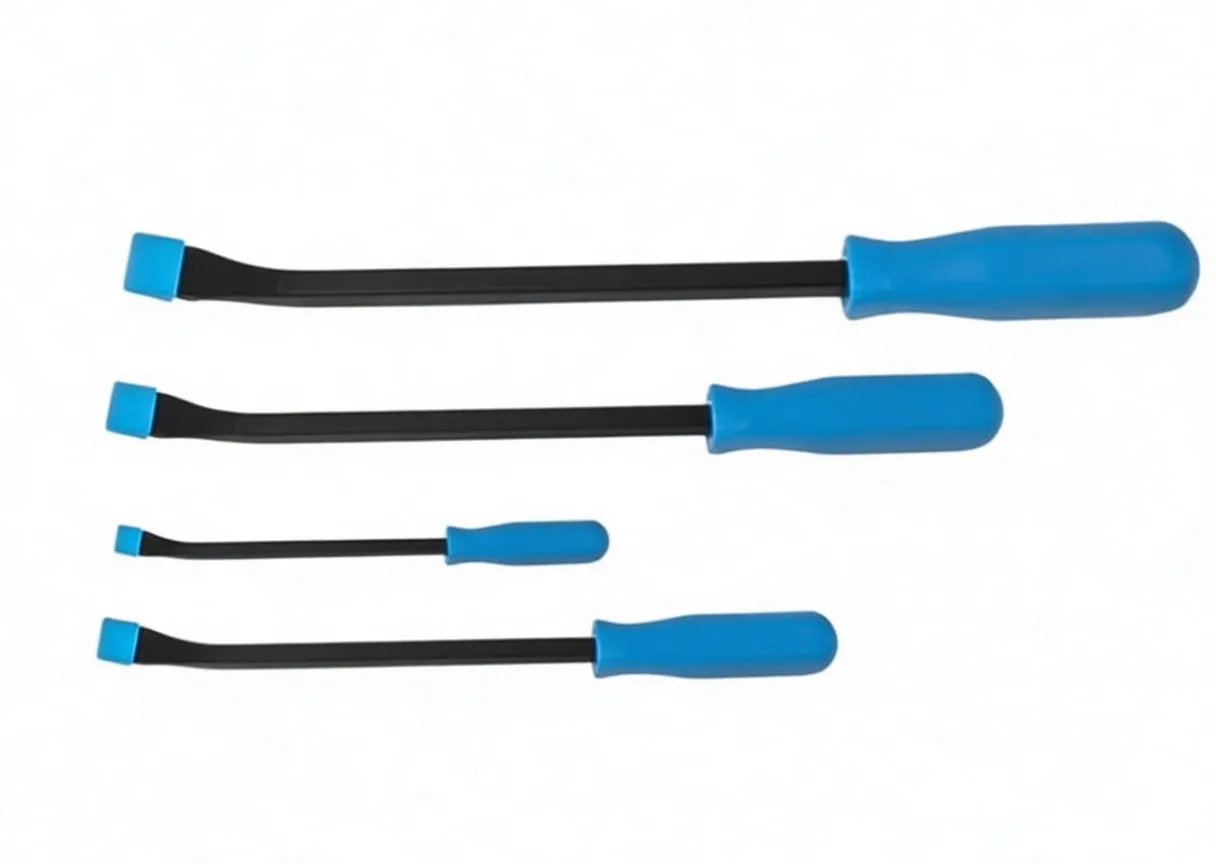

4-Piece Drop-Forged Pry Bar Set, 200mm to 600mm, Carbon Steel with Plastic Handles

Professional-grade 4-piece pry bar set in graduated sizes for automotive, construction, and maintenance work—heat-treated carbon steel with corrosion-resistant finish.

Request QuoteDescription

4-Piece Drop-Forged Pry Bar Set, 200mm to 600mm

Brief Overview

This 4-piece pry bar set delivers the essential leverage tools every shop and job site requires. Whether you're aligning components, lifting assemblies, or performing demolition work, this set covers the full range of applications from precision tasks to heavy-duty leverage. The graduated sizing (200mm, 300mm, 450mm, and 600mm) ensures you always have the right tool for the job without excessive reach-back.

For shops requiring additional leverage options, consider pairing this with a heavier-duty pry bar variant featuring a hammer end for applications demanding impact force, or a lighter-duty 3-piece alternative for space-constrained storage or specialized applications.

Key Features

- Four distinct sizes: 200mm, 300mm, 450mm, and 600mm lengths for varied leverage and precision requirements

- Drop-forged heat-treated carbon steel: Engineered for strength, durability, and consistent performance under load—resists bending under typical shop conditions

- Black powder coating: Corrosion-resistant finish withstands workshop and outdoor environments without degradation

- Graduated blade widths: 10mm, 15mm, 20mm, and 20mm respectively—optimized for different prying angles and load distribution to prevent damage to work surfaces

- Ergonomic molded plastic handles: Bright blue design reduces hand fatigue during extended use and improves visibility in cluttered work areas

- Protective blade caps: Included on larger bars to prevent accidental injury and safeguard finished surfaces during storage and transport

Why Resellers Stock This Set

Steady Turnover Across Sectors: Pry bars maintain reliable demand across automotive, construction, maintenance, and demolition operations. Tools are regularly replaced due to wear, loss, or repurposing to different job sites.

Margin-Friendly Configuration: Sourcing in 4-piece sets reduces per-unit logistics costs while allowing competitive retail pricing. Professional buyers expect to purchase in graduated sets rather than single bars, simplifying your inventory strategy.

Practical Coverage: The size range covers approximately 90% of common prying and alignment tasks, minimizing customer requests for additional bar sizes and reducing inventory complexity.

Durability Builds Reputation: Heat-treated, powder-coated construction results in fewer warranty claims and higher customer satisfaction. Shops recognize the difference between budget bars that bend and professional-grade tools that maintain precision over time.

Technical Specifications

| Specification | Details |

|---|---|

| Piece Count | 4 pry bars |

| Lengths | 200mm (8"), 300mm (12"), 450mm (18"), 600mm (24") |

| Blade Widths | 10mm, 15mm, 20mm, 20mm |

| Material | Drop-forged, heat-treated carbon steel |

| Finish | Black powder coating |

| Handle Type | Molded bright blue plastic, ergonomic grip design |

| Protection | Plastic blade caps on larger bars |

| Primary Applications | Alignment, component lifting, fixture prying, light demolition, seal removal |

Practical Applications

- Automotive: Panel removal, bearing extraction, component alignment, trim separation

- Construction: Formwork removal, flooring demolition, fixture extraction, controlled prying

- Maintenance & Repair: Seal and gasket removal, fixture leveling, precision placement

- General Purpose: Any controlled leverage task where surface damage must be minimized

Bottom Line for Your Customer

This set offers professional-grade durability at a competitive price point. The heat-treated carbon steel resists bending under typical load conditions, the powder coating withstands shop environments without rust or degradation, and the graduated sizing ensures the correct tool is always available for the job. Stock this confidently—it moves consistently across multiple customer segments and builds long-term customer loyalty through reliable, damage-resistant performance.