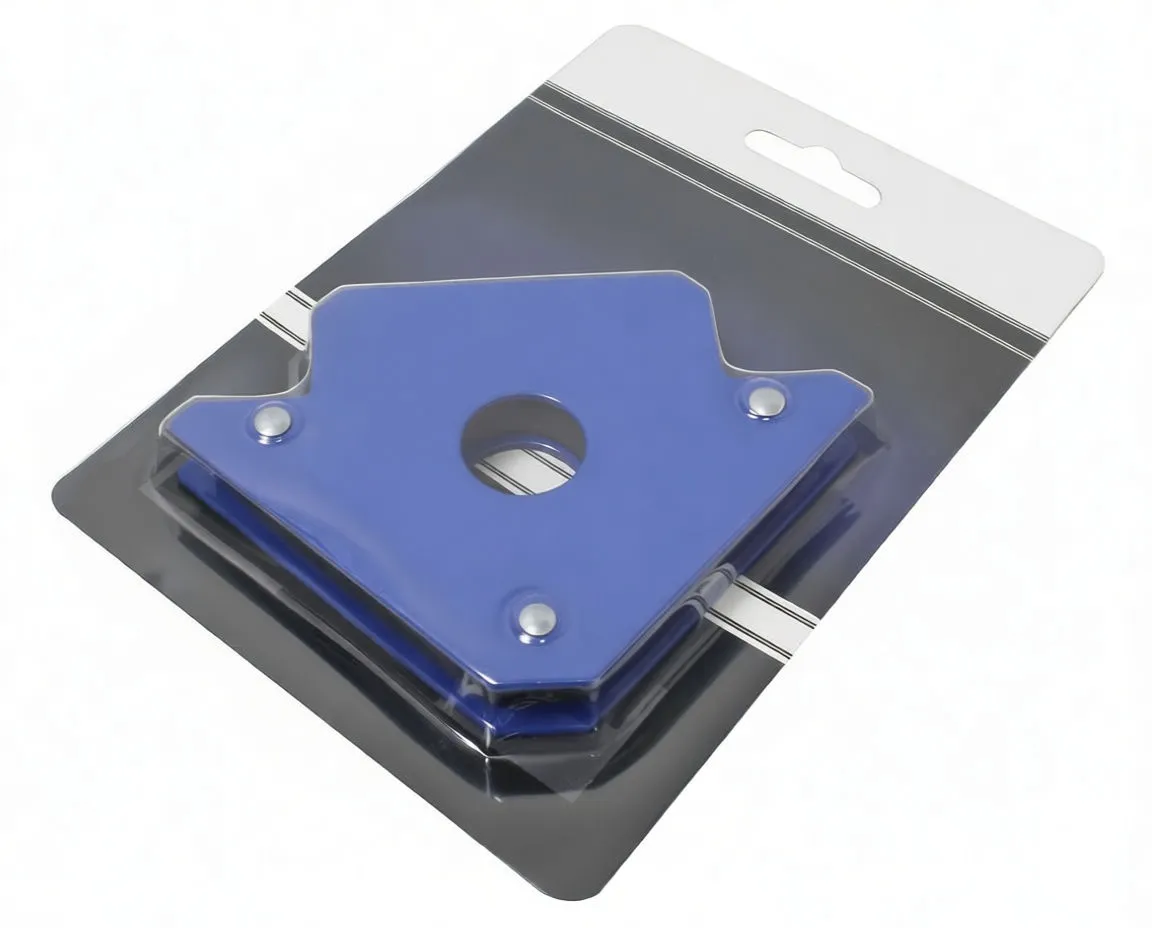

45°, 90°, 135° Magnetic Welding Holder, 25kg Holding Force, Riveted Steel Construction

Multi-angle magnetic holder for welding and soldering—holds workpieces at three positions with 25kg magnetic force.

Request QuoteDescription

45°, 90°, 135° Magnetic Welding Holder

Brief Overview

A robust magnetic positioning aid for welders, solderers, and fabricators who need reliable, hands-free workpiece alignment. This three-angle holder locks metal components at 45°, 90°, and 135° positions using 25kg (50lb) magnetic holding force. Built with durable steel plates and a riveted core, it's a workhorse for any shop that runs repetitive assembly, welding, or soldering operations. For shops handling higher volumes or tighter tolerances, consider pairing this with mini magnetic welding holders for smaller components or additional multi-angle positioning solutions.

Key Features

- Three Fixed Angles: 45°, 90°, and 135° positioning—covers the majority of common welding and soldering setups

- 25kg Magnetic Force: Sufficient to hold mild steel tubing, sheet metal, and standard fabrication workpieces without slipping

- Durable Riveted Construction: Steel outer plates with internal magnetic core; riveted assembly resists vibration and repeated use

- Compact Footprint: 102 × 155 × 17mm—fits tight workbenches and mounts easily in fabrication cells

- Central Handling Hole: 30mm diameter ring for secure grip and quick repositioning between jobs

- V-Groove Design: Notched edges engage round or angled stock; flat surfaces hold sheet metal and flat bar

Business Advantages for Resellers

- High-Velocity Item: Welding and soldering shops consume these regularly—steady reorder business

- Impulse-Friendly: Affordable price point encourages add-on purchases with larger tool orders

- Low Support Burden: Simple, mechanical design means minimal warranty claims or technical questions

- Margin-Friendly: Excellent cost-to-retail ratio; stack them for bulk distributor orders

- Replacement Driver: Magnetic wear is predictable; shops replenish when holding force degrades

Technical Specifications

| Specification | Value |

|---|---|

| Holding Force | 25kg (50lb) |

| Angle Positions | 45°, 90°, 135° |

| Overall Dimensions | 102 × 155 × 17mm |

| Handling Hole Diameter | 30mm |

| Construction | Riveted steel with magnetic core |

| Surface Finish | Blue powder coat |

| Weight | Approximately 400–500g |

| Suitable Metals | Mild steel, stainless steel (reduced force), ferrous metals |

Typical Applications

- Welding: Holding tubing, flat stock, and angle iron at precise positions for tack and final welds

- Soldering: Suspending circuit boards, brackets, or assembly subcomponents at ergonomic angles

- Fabrication: Aligning parts for drilling, marking, or temporary clamping during assembly

- General Assembly: Quick-change workpiece positioning for repetitive operations

Why Distributors Stock This

Shops that weld daily will own multiple units—one for each workbench or fixture type. The 25kg force balances practicality with affordability; it's strong enough for real work without the premium price of heavier industrial magnets. Riveted construction ensures durability in dusty, vibration-heavy environments where cheaper alternatives fail quickly.

Stock confidently. Reorder regularly. Profit predictably.