7-Inch Pneumatic Angle Disc Grinder, 1000W, 7,600 RPM

Professional-grade 7-inch pneumatic angle grinder delivering 1000W power for heavy-duty grinding, cutting, and surface preparation in industrial workshops.

Request QuoteDescription

7-Inch Pneumatic Angle Disc Grinder

Brief Overview

This 7-inch pneumatic angle grinder is engineered for high-volume grinding, cutting, and surface finishing operations in professional workshops and industrial facilities. The 1000W motor delivers consistent power at 7,600 RPM, making it ideal for tackling everything from metal fabrication to structural steel preparation. Designed for extended production runs, this tool combines robust construction with balanced ergonomics to minimize operator fatigue during demanding tasks. For shops requiring versatility across disc sizes, consider complementary solutions like our smaller 5-inch high-speed angle grinder or our compact 4-inch pneumatic model for precision work in confined spaces.

Key Features

- Powerful 1000W Motor – Sustained cutting and grinding force across a full 7-inch disc diameter

- 7,600 RPM Free Speed – Optimal performance window for production-level grinding operations

- Balanced Vibration Control – Body vibration at 4.32 m/s² and grip vibration at 6.65 m/s² engineered for operator safety and control

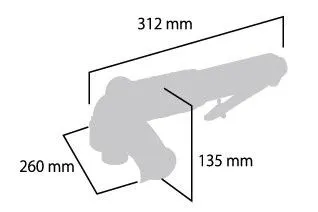

- Extended Operational Handle – 312mm length with ribbed auxiliary side grip for secure two-hand control during sustained use

- Quick-Change Disc System – Metal backing plate and spindle flange nut designed for rapid disc changes between grinding and cutting operations

- Wheel Guard Protection – Full-coverage metal guard shields operator from disc ejection and sparks

- Industrial-Grade Air Inlet – 3/8-inch connection (standard compressed air coupling) with 8.5 L/sec consumption rate

Business Advantages for Resellers

Volume & Margin Potential: The 7-inch segment represents the workhorse category in industrial pneumatic tools—high demand from metal fabricators, shipyards, automotive body shops, and structural steel contractors. This disc size balances material removal rate with operator control, making it the most frequently reordered tool class.

Durability & Service Revenue: Pneumatic grinders generate recurring revenue through consumable disc sales and wear component replacement (backing plates, flanges). The robust red aluminum housing and metal guard withstand job-site conditions that would compromise lighter models.

Compressed Air Infrastructure Compatibility: At 8.5 L/sec consumption, this tool operates efficiently on standard shop air systems (typically 6–8 bar), reducing customer upfront investment in compressor capacity compared to electric alternatives.

Competitive Positioning: Pneumatic angle grinders command higher margins than cordless or electric models while offering superior power delivery in continuous-duty environments. No battery replacement costs; no electric supply constraints on remote work sites.

Technical Specifications

| Specification | Value |

|---|---|

| Free Speed | 7,600 RPM |

| Motor Power | 1,000W |

| Disc Diameter | 7 inches (178mm) |

| Air Consumption | 8.5 L/sec |

| Air Inlet | 3/8 inch |

| Noise Level | 84.5 dB (press) / 95.5 dB (power) |

| Vibration (Body) | 4.32 m/s² (a) / 1.39 m/s² (k) |

| Vibration (Grip) | 6.65 m/s² (a) / 2.14 m/s² (k) |

| Overall Length | 312 mm |

| Overall Width | 260 mm |

| Overall Height | 135 mm |

| Weight | 3,300 g (3.3 kg) |

Recommended Applications

- Metal fabrication and welding preparation

- Structural steel surface finishing

- Concrete and masonry grinding

- Paint and rust removal on heavy machinery

- Shipyard and automotive body shop operations

- General-purpose material removal in manufacturing

Value Proposition for Your Customers

This grinder positions as the reliable production tool—proven performance in high-demand environments where downtime translates directly to lost revenue. The pneumatic platform offers unmatched power-to-weight ratio, infinite runtime on compressed air, and straightforward maintenance. Professional operators appreciate the balanced vibration profile and secure two-handle control during sustained grinding operations.

Stock this model to serve customers who grade tools by throughput and reliability rather than convenience features.