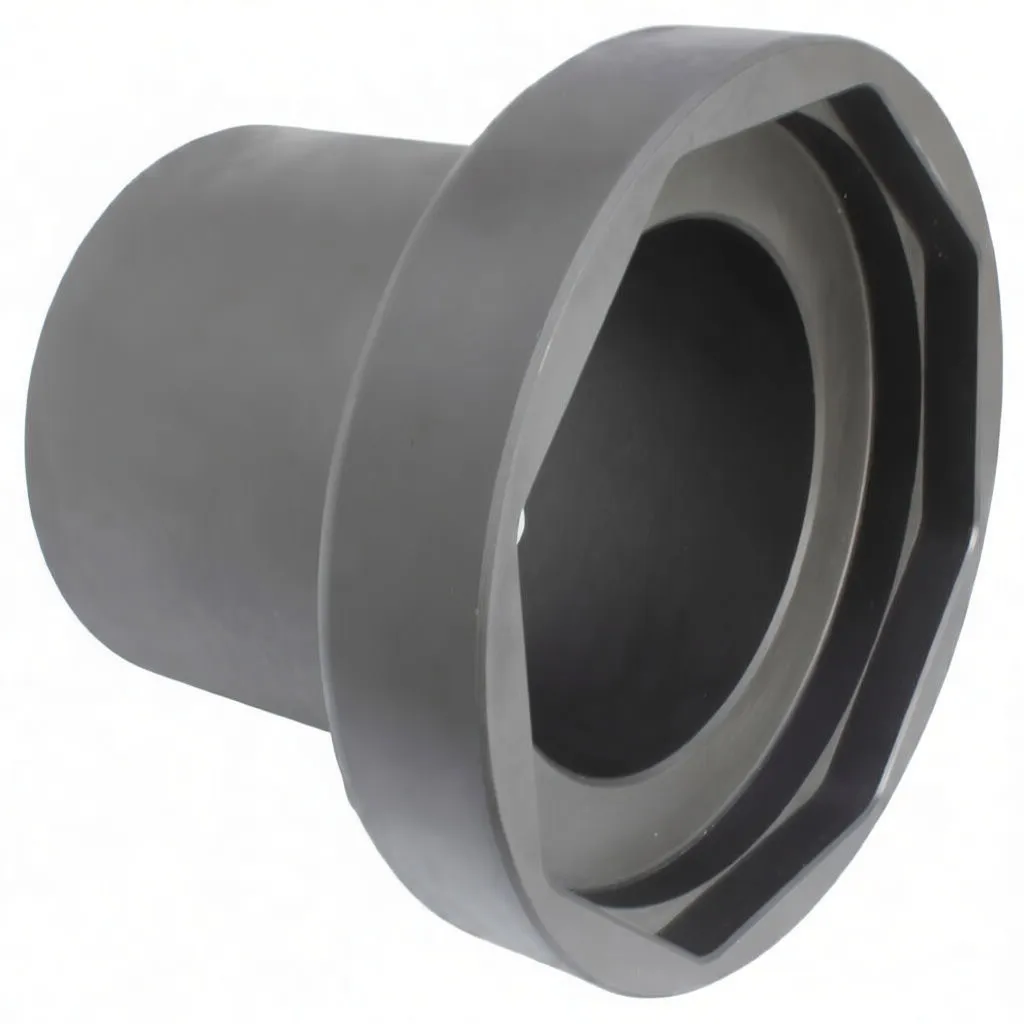

8-Sided Hub Socket with Flanged Design and Retention Pin

Heavy-duty 8-sided hub socket with wide flange and pin retention, engineered for professional automotive and industrial hub applications.

Request QuoteDescription

8-Sided Hub Socket with Flanged Design and Retention Pin

Brief Overview

This is a specialized 8-sided hub socket designed for wheel hub removal and installation on heavy-duty vehicles. The flanged design provides a wide grip surface, while the internal octagonal profile engages directly with hub fasteners. The retention pin hole ensures secure tool coupling during operation, making this an essential addition to any professional shop's hub service toolkit.

Key Features

- 8-Sided Octagonal Profile: Precisely machined internal geometry for positive contact with hub fasteners

- Wide Flanged Design: Thick, slightly chamfered outer rim provides excellent grip and leverage surface

- Deep Central Cavity: Accommodates hub geometry for maximum reach and engagement

- Pin/Retainer Hole: Circular side port allows locking pin insertion for secure tool coupling during high-torque operations

- Impact-Rated Construction: Matte oxidized steel finish indicates heavy-duty, impact-resistant material suitable for pneumatic and manual torque applications

- Radiused Inner Edges: Smooth internal chamfering reduces stress concentration and prevents fastener damage

Why Resellers Choose This Tool

Professional Demand: Hub sockets are specialized tools with consistent demand in independent repair shops, dealerships, and fleet maintenance facilities. These customers cannot substitute this tool with generic sockets—it's a must-have for wheel service.

Margin Opportunity: Specialized hub tools command higher margins than standard sockets because they serve a specific, non-negotiable function. Shops that perform brake work, suspension service, or tire replacement will stock these as core equipment.

Stock Efficiently: The single design focuses inventory on a high-turnover item. No size variations mean simpler inventory management and faster reorder cycles.

Upsell Potential: Hub sockets pair naturally with impact wrenches, pneumatic tools, and wheel service kits—creating bundling opportunities with higher transaction values.

Technical Overview

This hub socket is engineered for direct fastener engagement on vehicle wheel hubs. The 8-sided (octagonal) recess matches OEM hub fastener geometry, ensuring precise fit and maximum torque transfer. The flanged design distributes load across a wider contact area, reducing concentrated stress on the fastener and socket walls—critical for preventing cam-out and premature wear.

The retention hole accommodates a locking pin (typically a ball detent or spring pin), which secures the socket to the drive tool during operation. This feature is essential when working with impact wrenches or applying high torque, as it prevents accidental socket separation.

The matte, oxidized steel finish indicates the material has been treated for corrosion resistance and impact performance. This finish is standard on professional-grade sockets designed for daily shop use in humid, chemically active environments.

Technical Specifications

| Specification | Detail |

|---|---|

| Socket Type | 8-Sided Hub Socket (Octagonal Internal Profile) |

| Flange Design | Wide, thick-walled with slight chamfer |

| Central Cavity | Deep cylindrical well for hub geometry accommodation |

| Retention Feature | Side pin/retainer hole for locking pin coupling |

| Material | Impact-rated steel with oxidized finish |

| Surface Finish | Matte, oxidized (corrosion and impact resistant) |

| Construction | Heavy-duty, one-piece machined design |

Application Context

This socket is specifically designed for:

- Wheel hub removal and installation on passenger and light commercial vehicles

- Brake service requiring hub access and fastener engagement

- Suspension work involving hub nut removal

- Tire and wheel service in professional repair facilities

- Manual and pneumatic torque application via compatible drive tools

Call to Value

Stock this specialized hub socket to serve the wheel and brake service segment of your customer base. It's a tool that cannot be substituted, has consistent demand, and commands professional-grade pricing. Pair it with impact wrenches and pneumatic tools for maximum sales potential.