8mm Cylindrical Milling Drill ZYA Type, 65mm Length, 6mm Shank

Precision cylindrical milling burr with cross-cut flutes for smooth surface finishing in tight tolerances and intricate geometries.

Request QuoteDescription

8mm Cylindrical Milling Drill ZYA Type, 65mm Length, 6mm Shank

Overview

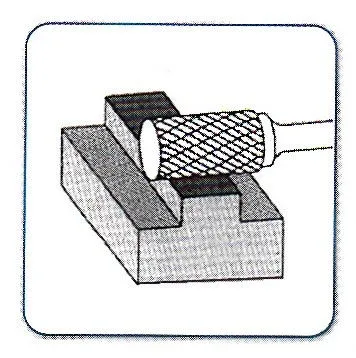

This is a precision cylindrical milling burr engineered for controlled material removal in demanding finishing operations. The 8mm head diameter with cross-cut flute pattern delivers smooth, repeatable surface finishes on complex geometries—critical for tool & die shops, precision job shops, and aerospace component manufacturers where surface quality directly impacts function. The reduced-neck design minimizes vibration during lateral machining, making it essential for deburring narrow slots, finishing inside corners, and refining shoulder transitions. For shops requiring broader tooling depth, consider pairing this burr with larger 12mm cylindrical cutting heads or smaller precision finishing options to build a complete finishing toolkit.

Key Features

- Cylindrical cutting head with diamond-style cross-cut flute pattern for consistent, smooth material removal

- Reduced-neck shank design minimizes chatter and vibration during precision work

- Straight 6mm shank compatible with standard rotary tool chucks and handpiece collets

- Polished metallic finish resists corrosion and facilitates easy workholding identification

- Flat end face on cutting head prevents dig-in and supports controlled lateral feeding

- Compact 65mm overall length fits standard rotary tool handpieces without extension limitations

Business Advantages for Resellers

- High-margin tooling category: Milling burrs command consistent demand across job shops, tool & die operations, and precision manufacturing environments

- Predictable reorder cycles: While durable, regular wear patterns create reliable repeat purchase frequency from existing customers

- Basket-building opportunity: Stock multiple head diameters and cutting patterns to capture single-order upgrades from shops expanding their finishing capabilities

- Positioning asset: Precision surface-finish capability positions your shop as capable of high-tolerance work—attracting premium customers and justifying higher pricing tiers

Technical Specifications

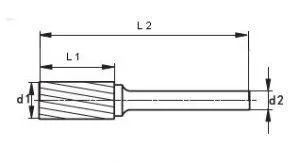

| Specification | Value |

|---|---|

| Head Diameter (d1) | 8 mm |

| Head Length (L1) | 20 mm |

| Shank Diameter (d2) | 6 mm |

| Overall Length (L2) | 65 mm |

| Design Type | Straight Shank, Cylindrical |

| Cutting Pattern | Cross-Cut / Diamond Flute |

| Head End | Flat Face (End-Cutting) |

Application Context

This tool excels in:

- Tool and die shops: Finishing complex cavity geometries and shoulder details with repeatable precision

- Precision job shops: Deburring and edge-breaking on critical components requiring tight surface finish control

- Aerospace and medical manufacturing: Where surface finish directly impacts assembly fit or functional performance

- Slot and keyway finishing: Controlled lateral machining in confined spaces without excessive chatter

- Stepped workpiece transitions: Refining shoulders and interior corner radii on multi-feature parts

Reseller Recommendation

Stock this 8mm burr as the centerpiece of a complete ZYA series finishing toolkit. Different head diameters and shank configurations address different workpiece features and spindle requirements—a standard reseller inventory approach that increases average order value and customer retention. Pair with larger head diameter alternatives for shops transitioning to bigger components or batch work.

A reliable precision tool built for repeated use in shops where surface finish is non-negotiable.