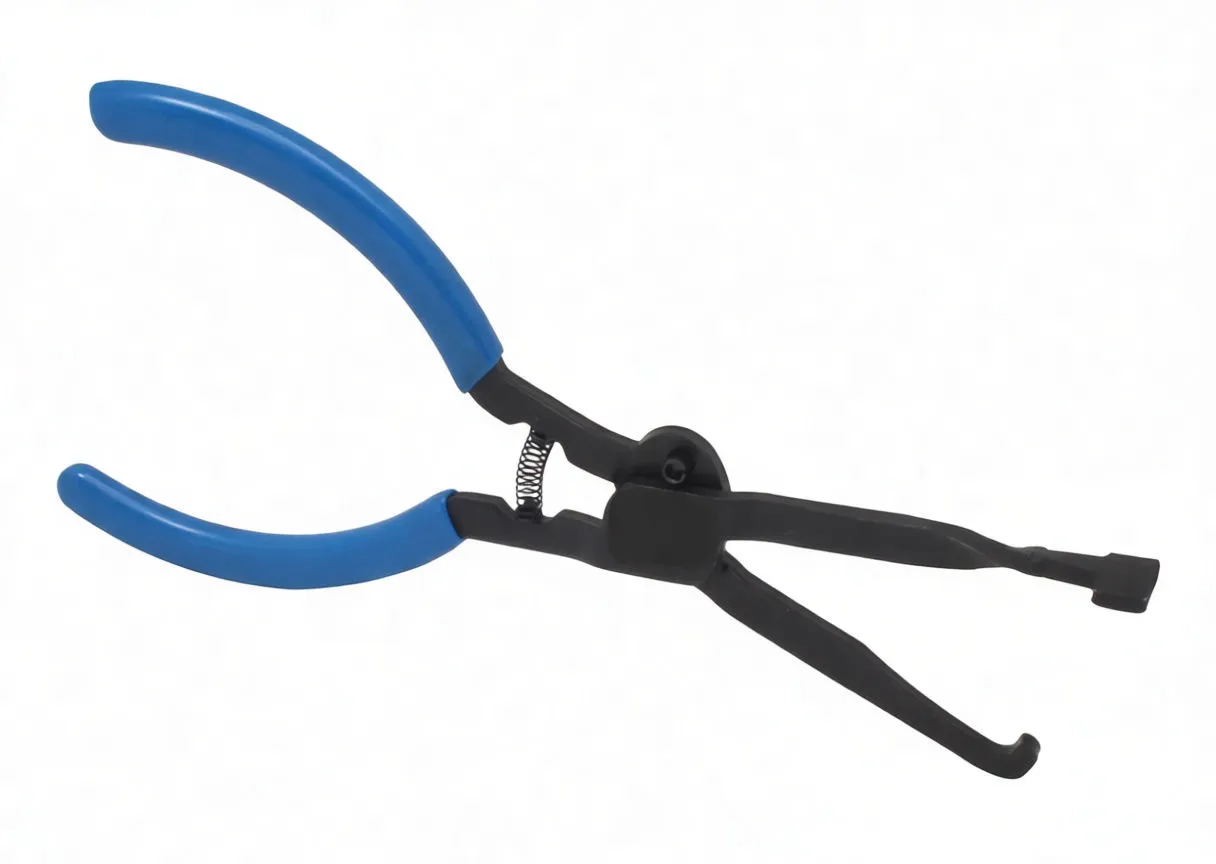

9-Inch Electrical Disconnect Pliers for Automotive Connectors

Precision tool for safely removing push-tab electrical connectors on fuel injectors, sensors, and ignition coils without damage.

Request QuoteDescription

9-Inch Electrical Disconnect Pliers for Automotive Connectors

Brief Overview

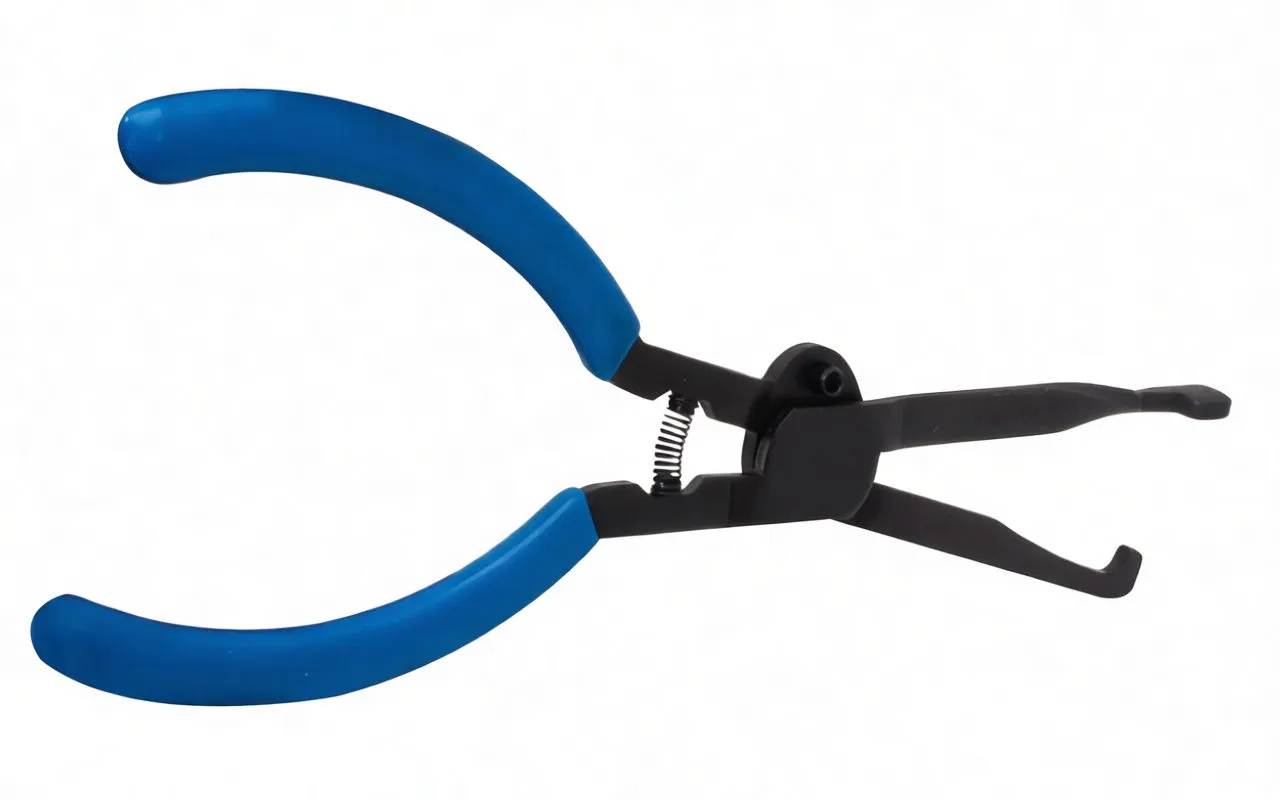

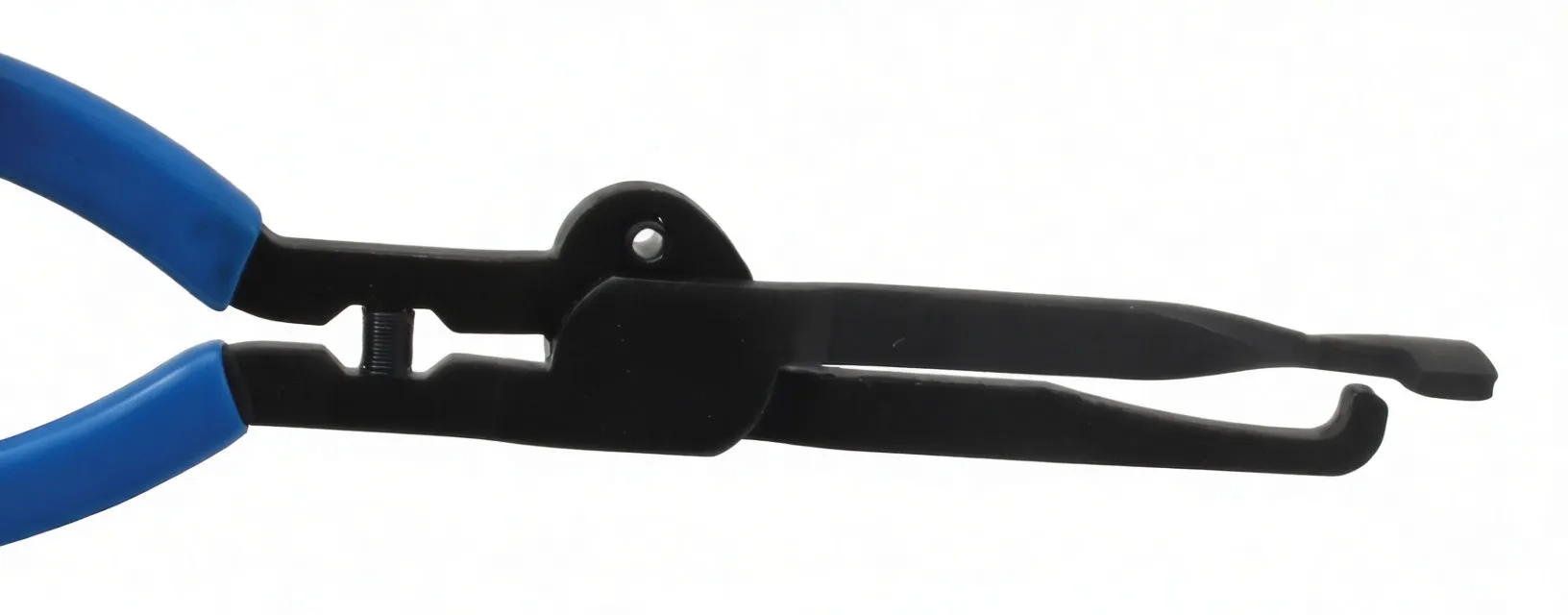

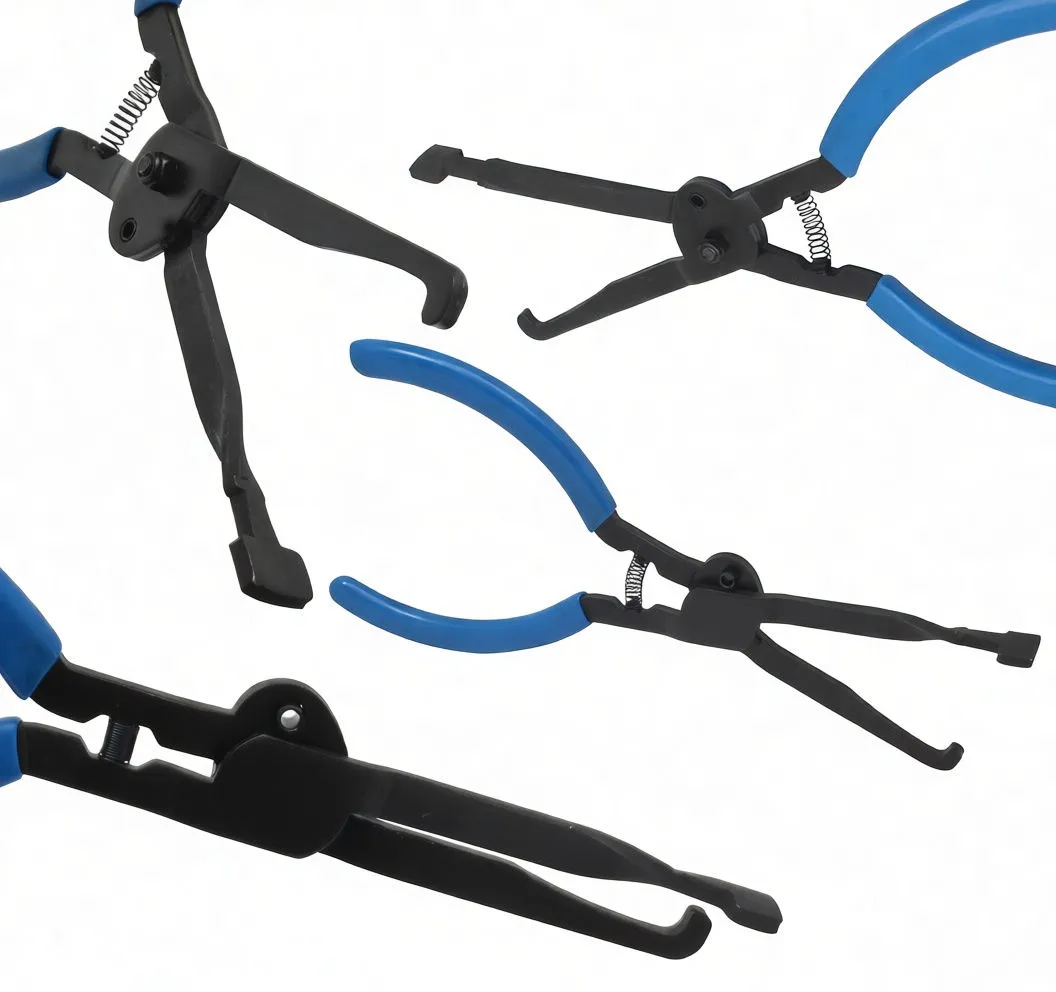

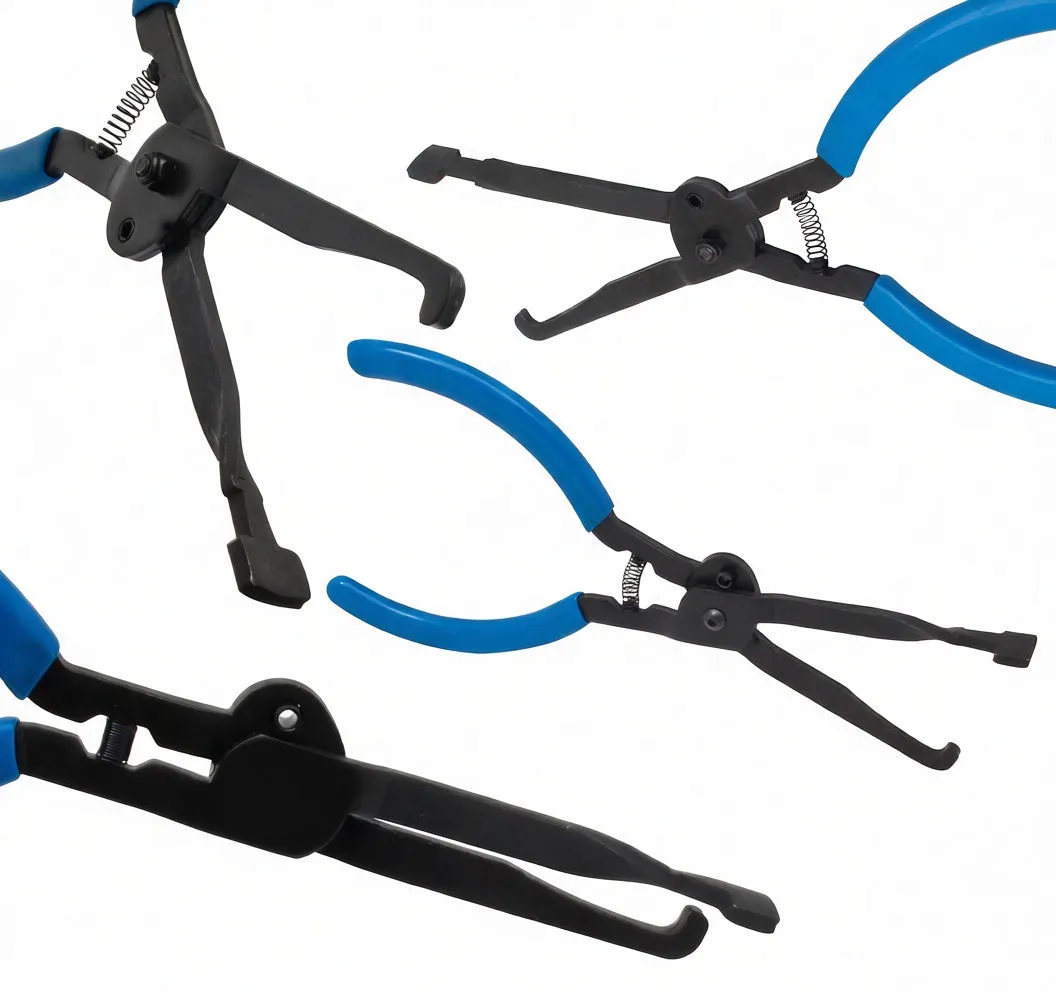

This 9-inch electrical disconnect pliers is a specialized hand tool engineered specifically for safely removing locking push-tab style electrical connectors found throughout modern automotive electrical systems. The dual-jaw design combines a hooked engagement tip with a flat disengagement pad, allowing technicians to unlock and separate connectors from fuel injectors, mass air flow sensors, ignition coils, and similar applications without risk of damage to the connector housing or sensor terminals. Designed for one-handed operation in confined engine compartments, this tool pairs exceptionally well with clip removal pliers for automotive plastic components and spark plug terminal pliers to create a complete electrical connector service kit.

Key Features

- Dual-Function Jaw Design: Hooked tip engages and lifts the locking tab; flat spade pad provides leverage for clean separation

- One-Handed Operation: Ergonomic blue plastic-coated handles enable control in tight spaces without requiring a secondary tool or hand

- Spring-Return Mechanism: Coil spring between handles automatically opens the jaws after release, reducing technician fatigue during repetitive disconnects

- Non-Damaging Separation: Geometry prevents cam-out or connector housing deformation—critical for modern vehicles where sensor replacement costs justify proper extraction

- Durable Construction: Black powder-coated steel jaws and riveted pivot provide reliable performance across thousands of connector cycles

- 9-Inch Overall Length: Full reach into deep engine bays while maintaining maneuverability in confined spaces

Why Resellers Should Stock This Tool

High-Demand Application: Fuel injector and sensor connector removal is a routine service procedure at any shop performing electrical diagnostics, fuel system work, or sensor replacement. Shops performing these services must have the correct extraction tool to avoid customer complaints and warranty claims.

Repeatable Revenue: Unlike consumables, this tool generates profit on every job where it's used—technicians will recommend purchase to shops that lack it, and shops will order replacements when tools are lost or worn.

Complementary to Your Existing Lineup: Pairs naturally with plier sets, electrical diagnostic tools, and sensor replacement kits. Cross-sell aggressively to shops purchasing fuel injector or MAF sensor service items.

Professional Positioning: Offering this tool signals your company understands automotive electrical work. Shops recognize OEM-quality hand tools and trust suppliers who stock them.

Technical Specifications

| Specification | Detail |

|---|---|

| Overall Length | 9 inches (228 mm) |

| Jaw Design | Hooked engagement tip + flat disengagement pad |

| Handle Material | Plastic-coated (blue) with ergonomic curve |

| Jaw Material | Black powder-coated steel |

| Pivot Type | Riveted with coil return spring |

| Operating Style | One-handed squeeze and lift |

| Primary Applications | Fuel injectors, MAF sensors, ignition coils, electrical connectors with push-tab locking mechanisms |

Call to Value

Stock this tool for shops that service fuel systems, perform electrical diagnostics, or replace sensors and ignition coils. It eliminates one of the most common causes of damaged connectors in the field—improper extraction with incorrect tools. Offer it as a value-add to any fuel system or sensor service package, and watch shop technicians request it by name.