AC220V Solenoid Magnetic Valve, 6.0VA 50Hz, IP65 Rated

Industrial-grade solenoid valve with AC220V coil, IP65 protection, and ready-to-install terminal connections for pneumatic and fluid control systems.

Request QuoteDescription

AC220V Solenoid Magnetic Valve, 6.0VA 50Hz, IP65 Rated

Brief Overview

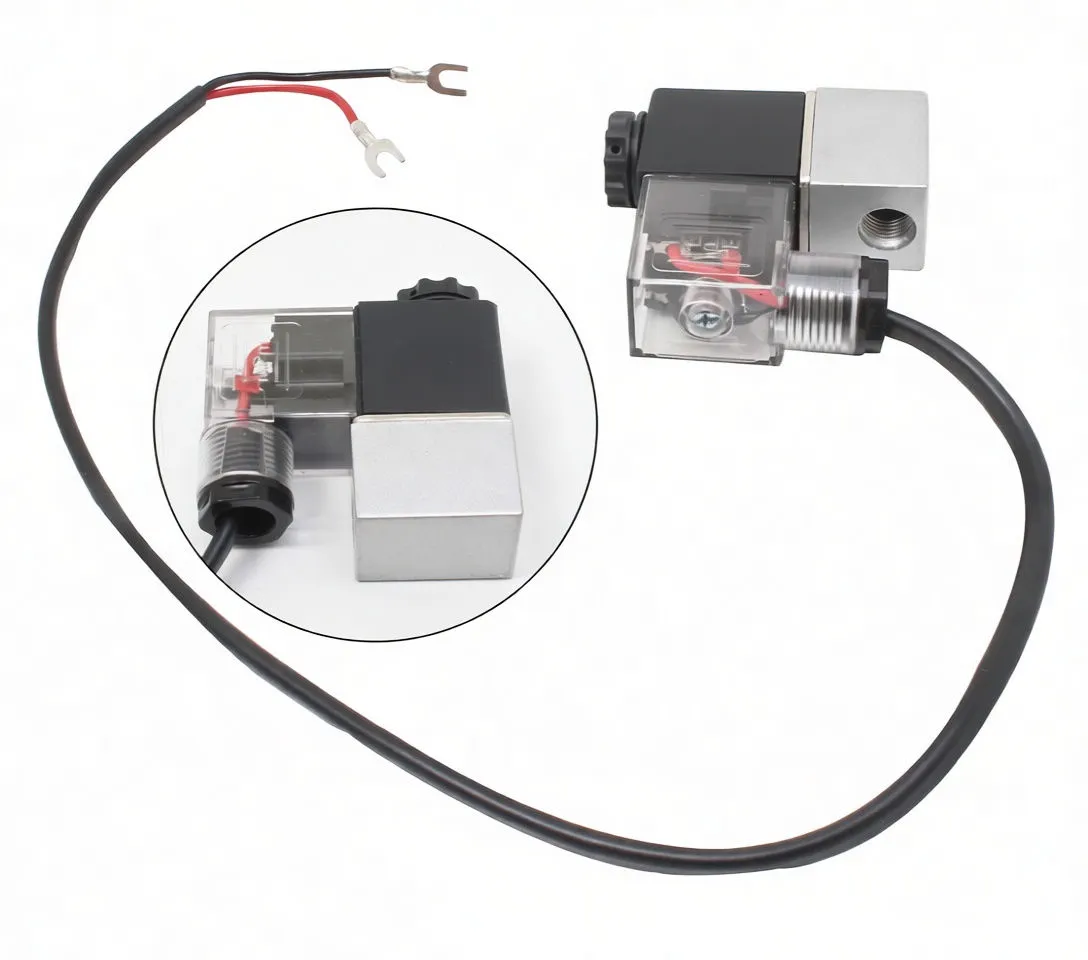

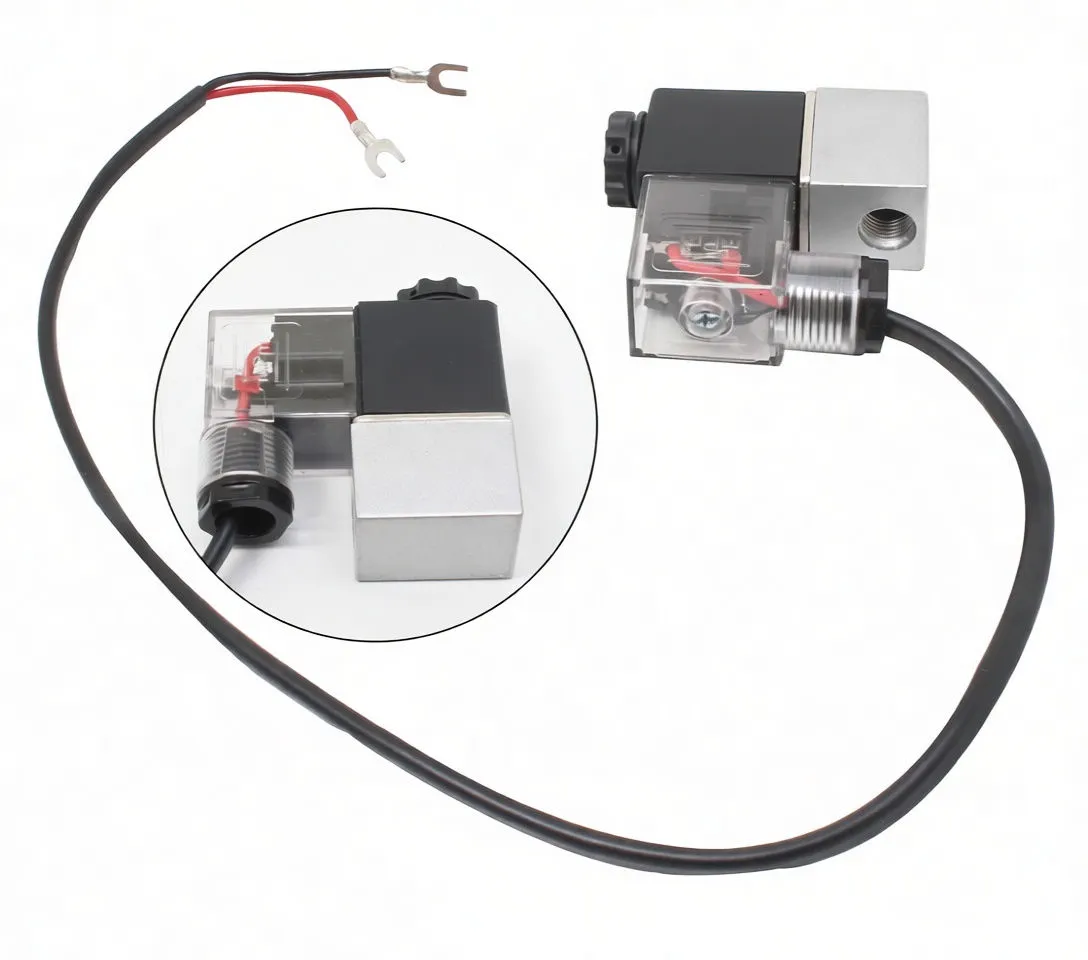

This is a robust solenoid-operated magnetic valve designed for direct integration into pneumatic, hydraulic, and fluid control systems. The unit combines a precision-machined aluminum valve body with a sealed AC-powered solenoid coil assembly, offering reliable electromagnetic switching for industrial applications. The IP65-rated construction ensures protection against dust and water spray, making it suitable for workshop, manufacturing, and outdoor equipment environments.

Key Features

- AC220V Solenoid Coil – 6.0VA at 50Hz (4.5VA at 60Hz) with wide voltage tolerance (AC187V–253V)

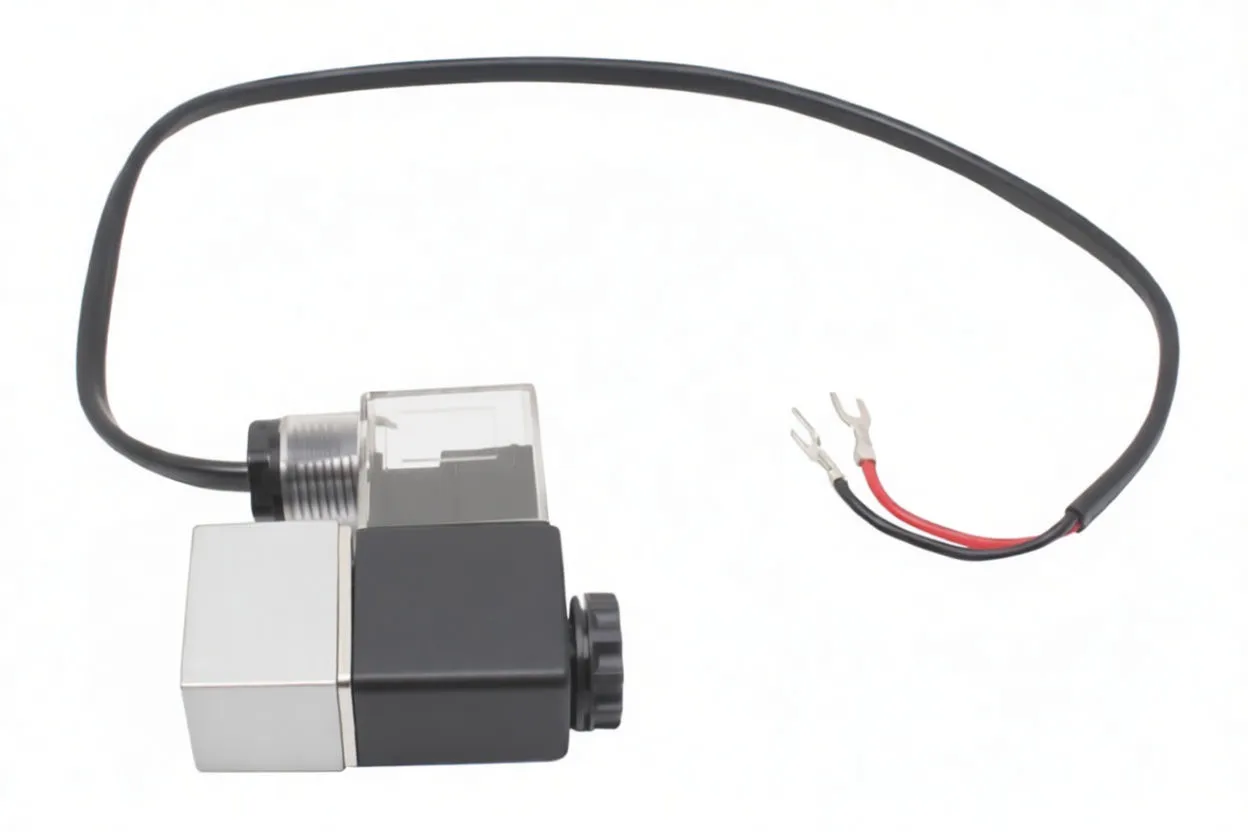

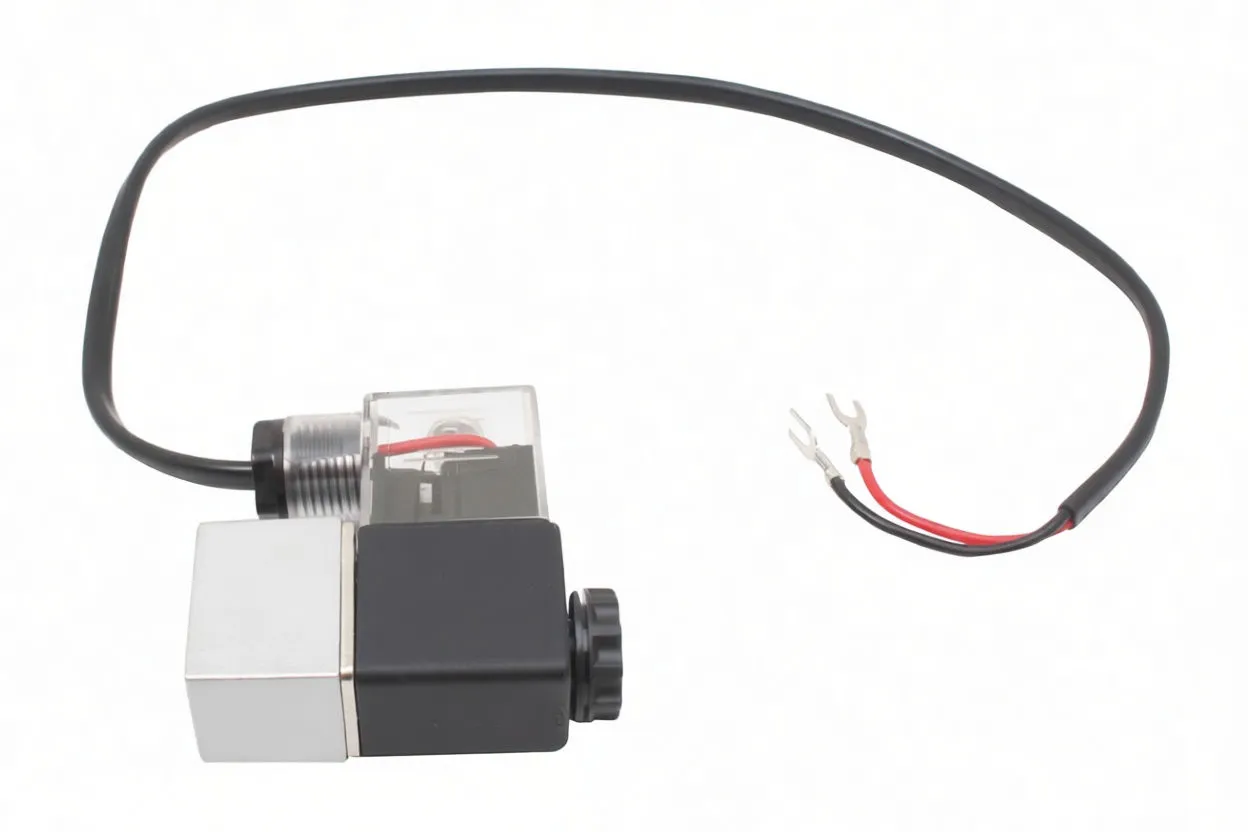

- Compact Aluminum Valve Body – Precision-machined with threaded fluid port for direct line integration

- IP65 Protection Rating – Sealed against dust and low-pressure water jets; suitable for harsh shop environments

- 100% Duty Cycle (ED) – Designed for continuous operation without thermal cycling restrictions

- Fork Terminal Wiring – Pre-fitted with color-coded leads (red/black) and metal spade connectors for quick electrical hookup

- Integrated Cable Gland – Secure threaded entry point with strain relief; long external cable for flexible installation positioning

- Low Amperage Draw – 29mA operating current minimizes electrical demand on control circuits

- Moderate Temperature Rise – 35°C rise ensures safe operation in standard industrial enclosures

Business Advantages for Resellers

High-Demand Component: Solenoid valves are consumable control elements in pneumatic systems, with frequent replacement demand across industrial maintenance, manufacturing OEM kits, and equipment refurbishment.

Versatile Application Base: This voltage/power specification (AC220V, 6.0VA) is standard across European industrial equipment, ensuring broad compatibility with existing customer machinery and control panels.

Compact Footprint: The aluminum body design allows easy integration into existing manifold systems or valve banks without requiring complete system redesign—reducing customer installation costs and increasing order frequency.

Reliability and Certification: IP65 rating and CE marking provide documented compliance for professional installations, reducing liability and supporting premium positioning in your catalog.

Consistent Margin Opportunity: As a control component with predictable failure intervals, solenoid valves generate recurring orders from maintenance contracts and equipment service programs.

Technical Specifications

| Specification | Value |

|---|---|

| Supply Voltage | AC220V (50Hz) / AC220V (60Hz) |

| Power Consumption | 6.0VA (50Hz); 4.5VA (60Hz) |

| Voltage Range | AC187V–253V |

| Operating Current | 29mA |

| Duty Cycle | 100% ED (continuous operation) |

| Temperature Rise | 35°C |

| Protection Rating | IP65 (dust and water-jet resistant) |

| Valve Body Material | Precision-machined aluminum |

| Terminal Type | Fork spade connectors (red/black leads) |

| Cable Entry | Threaded gland with strain relief |

| Certifications | CE marked |

Call to Value

Stock this solenoid valve as a core control component for pneumatic system maintenance and OEM kit assembly. The AC220V/6.0VA specification, combined with IP65 durability and 100% duty cycle capability, positions it as a reliable control solution that your customers will reorder regularly. The integrated wiring and fork terminals reduce installation labor, supporting faster customer turnaround and higher satisfaction rates.