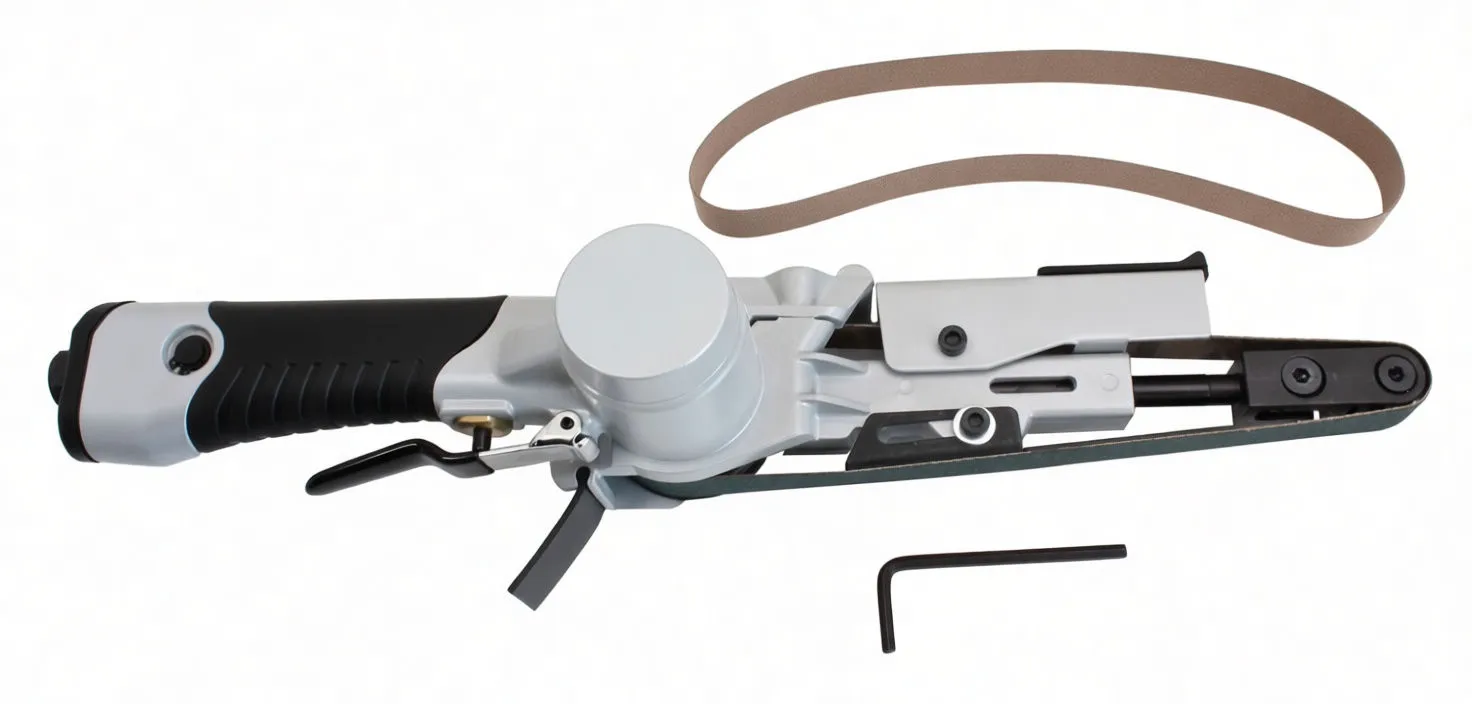

Air Belt Sander 20×520mm Articulated Sanding Arm, 16,000 RPM Pneumatic

Professional pneumatic belt sander with articulated arm for automotive buffing and metalwork finishing. Quick-change belt, low vibration, 220 L/min air consumption.

Request QuoteDescription

Air Belt Sander 20×520mm Articulated Sanding Arm, 16,000 RPM Pneumatic

Brief Overview

This pneumatic belt sander combines high-speed performance with ergonomic design, making it an essential tool for automotive detailing, metalwork finishing, and precision surface preparation. The 20×520mm abrasive belt delivers consistent material removal at 16,000 RPM, while the articulated arm provides operator control and access to contoured surfaces. For shops managing multiple sanding applications, this unit complements broader sanding operations—pair it with an orbital palm sander for detailed finishing work or a compact belt sander for smaller projects to maximize throughput across different job types.

Key Features

- 20×520mm abrasive belt – Optimal width and length for medium to large surface areas

- 16,000 RPM free speed – Aggressive material removal without sacrificing control

- Articulated sanding arm – Provides flexibility for contoured work and angled surfaces

- Quick-change belt system – Reduces downtime between jobs; simple hex key operation

- Adjustable arm angle – Accommodates variable sanding angles for optimal finish quality

- Dual roller drive system – Smooth belt tracking and consistent tension

- Low vibration design – 2.5 m/s vibration level reduces operator fatigue on extended use

- Handle exhaust – Directs dust and air flow away from operator

- Included accessories – Replacement sanding belt (80 grit) and L-shaped hex key provided

Business Advantages for Resellers

- Efficient belt changeover – Quick-change mechanism reduces non-productive downtime, improving shop throughput

- Versatile application range – Articulated arm design expands usable applications (automotive prep, metal finishing, composite work)

- Durable construction – Vibration-reduced design extends tool life and reduces maintenance costs

- Operator comfort – Low vibration and ergonomic handle reduce fatigue complaints and support longer rental periods

- Competitive positioning – High-speed performance at moderate air consumption makes this attractive for shops with standard 3-4 HP compressor systems

- Accessory demand – Belt changeouts create ongoing consumable revenue; compatible abrasive belts (80, 120, 150 grit available separately)

Technical Specifications

| Parameter | Value |

|---|---|

| Sanding Belt Size | 20×520 mm |

| Free Speed | 16,000 RPM |

| Belt Material | Abrasive (grit specified per application) |

| Sanding Arm Length | 430 mm |

| Weight | 1.4 kg |

| Sound Level | 80 dB(A) |

| Air Consumption | 220 L/min |

| Vibration Level | 2.5 m/s |

| Drive System | Dual pneumatic piston |

| Air Connection | Standard industrial fitting (rear handle inlet) |

| Included Accessories | Replacement sanding belt (80 grit, ZK713X), L-shaped hex key |

Operational Context

This belt sander is engineered for continuous-duty automotive and metalworking applications. The 16,000 RPM speed is calibrated for aggressive stock removal on steel, aluminum, and composite surfaces without gouging. The articulated arm design distinguishes this from fixed-platform sanders, allowing operators to work around body contours, welded seams, and irregular geometries—critical for collision repair, restoration work, and custom fabrication.

Air consumption of 220 L/min requires a minimum 3 HP compressor system at continuous duty. The low vibration specification (2.5 m/s) supports extended operational periods without repetitive strain complaints—important for rental fleets and high-utilization shops.

Call to Value

Stock this unit for shops specializing in automotive surface preparation, metal fabrication, and restoration work. The combination of speed, articulation, and durability makes it a core tool for professionals who need control over complex sanding tasks. Pair with consumable abrasive belts in varying grits to establish recurring revenue while positioning yourself as a complete surface-finishing supplier.