Air Control Filter Regulator Unit with Lubricator and Water Trap, 1/2" BSP, 10 Bar Max

Complete air preparation system combining filtration, pressure regulation, and lubrication in one compact 1/2" BSP unit for pneumatic tool networks.

Request QuoteDescription

Air Control Filter Regulator Unit with Lubricator and Water Trap

Brief Overview

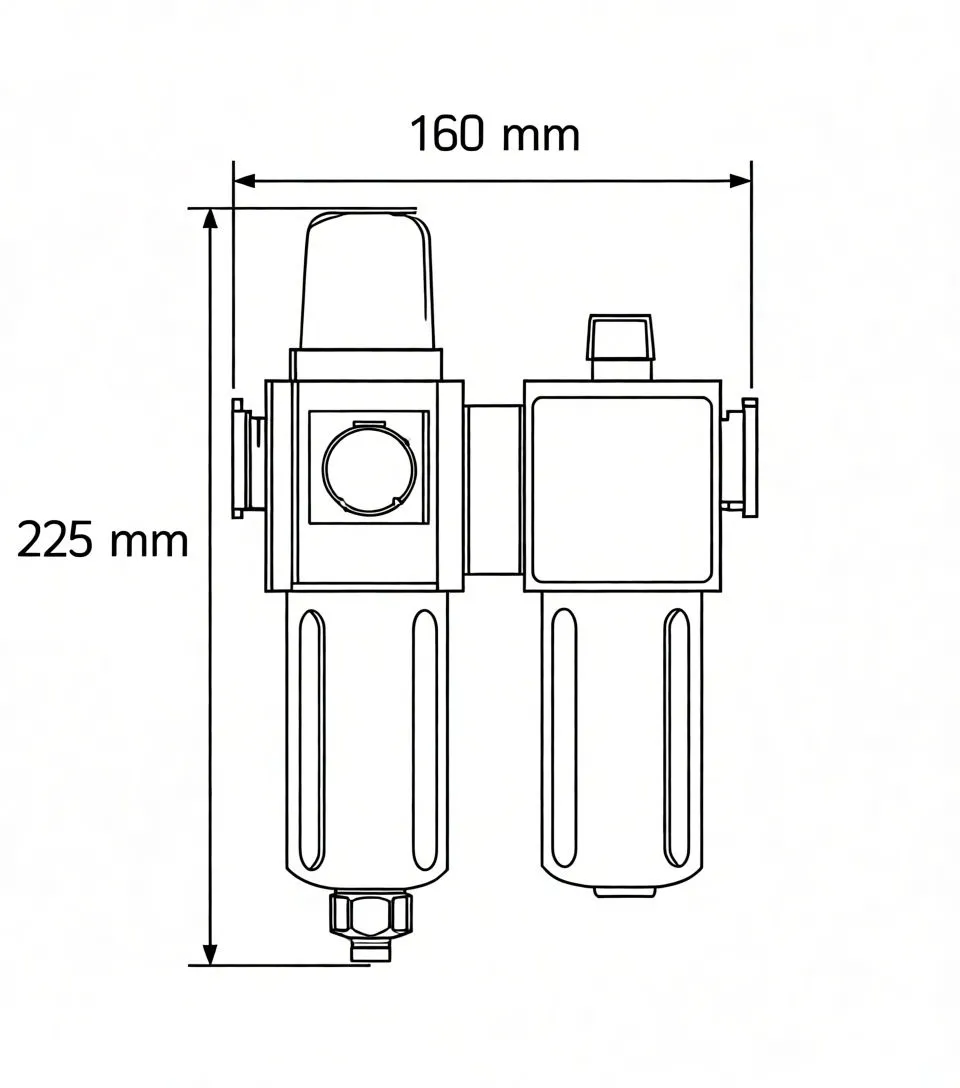

This integrated air preparation unit delivers essential filtration, pressure control, and tool lubrication in a single, space-efficient assembly. Designed for 1/2" BSP pneumatic systems, it addresses three critical air quality requirements simultaneously: removing particulates and moisture, maintaining stable operating pressure, and delivering precise oil mist to downstream pneumatic tools. The dual-bowl design separates filter and lubricator functions while maintaining a compact footprint (160 mm × 225 mm), making it ideal for workshop installations where bench or wall space is limited. Pair this with individual regulator units or compact inline lubrication systems for redundancy or multi-circuit setups.

Key Features

- Integrated 5 µm air filter – Removes dust, dirt, and airborne contaminants before tools receive compressed air

- Pressure regulator with dial gauge – 10 bar maximum rated pressure with real-time dual-scale gauge (bar and psi) for precise monitoring and adjustment

- Automatic water trap with 80 ml capacity – Condensation drain reservoir with blow-off valve prevents liquid carryover into tool circuits

- Lubrication reservoir (150 ml oil capacity) – Mounted lubricator delivers controlled oil mist for pneumatic tool longevity and performance

- 1/2" BSP thread connections – Standard industrial port size for direct integration into existing pneumatic layouts

- Aluminum mounting bracket with dual bowls – Silver-finished metal construction; vertical sight glasses on both filter and lubricator bowls for visual inspection of bowl fill and contamination levels

- Manual drain valve – Situated at the bottom of the filter bowl for easy maintenance and condensation removal

- Maximum operating temperature: 60°C – Suitable for general workshop and light industrial environments

Business Advantages for Resellers

- All-in-one solution – Single SKU replaces three separate purchases (filter, regulator, lubricator), reducing customer parts-list complexity and your inventory management overhead

- High-volume consumable appeal – Water and filter element replacement drives repeat orders; customers return for service parts regularly

- Professional workshop staple – Essential for any pneumatic tool operation; justifies stocking in quantity for fleet servicing and tool rental operations

- Competitive margin opportunity – Air preparation units command reliable margins when bundled with air tool kits or sold as maintenance bundles

- Compact installation footprint – Smaller than mounting three separate units; appeals to shops with limited wall/bench space, expanding your addressable market

Technical Specifications

| Specification | Value |

|---|---|

| Port Thread Size | 1/2" BSP |

| Maximum Operating Pressure | 10 bar |

| Air Consumption Capacity | 4000 L/min |

| Filter Element Micron Rating | 5 µm |

| Water Trap (Dewaterer) Capacity | 80 ml |

| Oil Reservoir Capacity | 150 ml |

| Maximum Operating Temperature | 60°C |

| Assembly Dimensions (Width × Height) | 160 mm × 225 mm |

| Pressure Gauge Scales | 0–11 bar (inner) / 0–160 psi (outer) |

| Material Finish | Aluminum bracket with metal bowls, silver/metallic |

| Drain Configuration | Manual drain valve on filter bowl bottom |

Closing Statement

This filter-regulator-lubricator unit represents the core of pneumatic system maintenance. Its integrated design reduces installation complexity while the 4000 L/min capacity handles typical shop-floor demand. Stock this unit confidently—air quality concerns are perennial in pneumatic operations, and this assembly directly addresses them with proven reliability.