Air Control Unit, 1/2-Inch Filter-Regulator-Lubricator (FRL) Assembly

Complete pneumatic air preparation unit with integrated filter, regulator, and lubricator. 1/2-inch ports, 4000 L/min capacity, 5-micron filtration.

Request QuoteDescription

Air Control Unit – 1/2-Inch FRL Assembly

Brief Overview

This is a modular pneumatic air preparation unit that combines three essential functions into a single, space-efficient assembly: air filtration, pressure regulation, and oil lubrication. The integrated design reduces plumbing complexity and minimizes footprint on the compressor line. If your shop requires multiple preparation stations, consider complementary air preparation units or modular filter systems for secondary air lines or specialized applications.

Key Features

- Three-in-One Function: Integrated filter, regulator, and lubricator eliminate the need for separate components

- 1/2-Inch Port Connection: Standard industrial fitting size compatible with most pneumatic systems

- 5-Micron Filtration: Removes moisture and particulates, protecting downstream tools and equipment

- Visual Monitoring: Transparent sight windows on both cylindrical bowls allow quick inspection of filter saturation and oil levels without disassembly

- Manual Drain Valves: Black threaded drain cap (regulator) and clear plastic drain plug (lubricator) for routine maintenance

- Pressure Gauge: Integrated dial gauge on the regulator module for real-time line pressure monitoring

- Adjustable Pressure Knob: Black plastic knob allows field adjustment of outlet pressure within operating limits

- Compact Mounting Bracket: Central bracket with two through-holes for secure wall or panel installation

- Robust Construction: Aluminum bowls with metal housings and plastic end caps for durability in shop environments

Technical Specifications

| Specification | Value |

|---|---|

| Port Size | 1/2" BSP/NPT |

| Filter Micron Rating | 5 µm |

| Maximum Air Flow | 4,000 L/min |

| Model Number | GFC-300-04 |

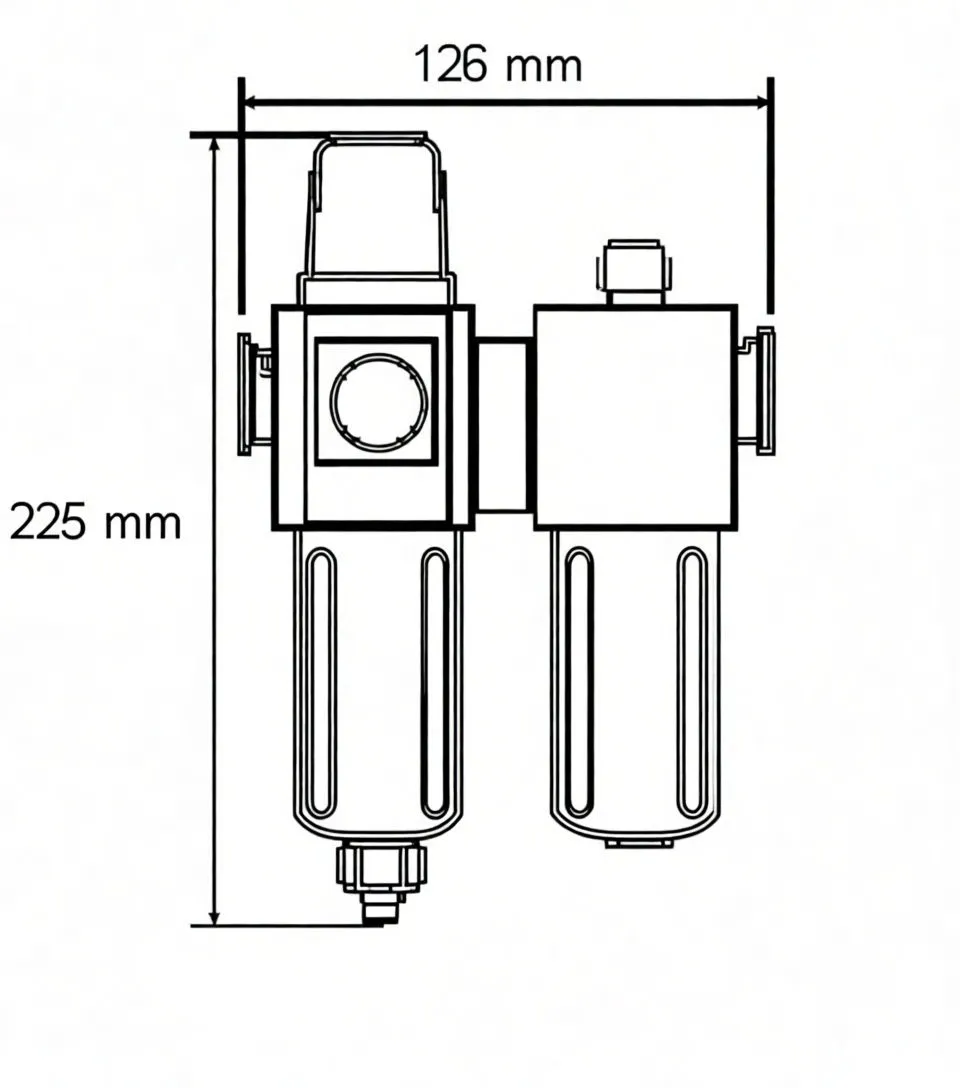

| Overall Width | 126 mm |

| Overall Height | 225 mm |

| Bowl Type | Transparent cylindrical (filter & lubricator) |

| Drain Type | Manual (threaded + quick-release) |

| Gauge Type | Dial pressure indicator (integrated) |

| Mounting | Central bracket with through-holes |

| Pressure Adjustment | Manual knob (field-adjustable) |

Business Advantages for Resellers

This FRL assembly is a high-turnover item in any professional shop because:

- Essential Maintenance Component: Every pneumatic system requires air preparation; this addresses a recurring need across multiple customer applications

- Standardized Sizing: 1/2-inch ports fit the majority of industrial and commercial compressor systems

- Preventive Tool Protection: Customers understand that proper filtration and lubrication extend tool life—this translates to customer loyalty and repeat orders

- Straightforward Replacement: Sight windows and accessible drain valves make this a self-service maintenance item, reducing shop labor costs

- Bulk Order Potential: Shops with multiple compressor lines or service departments often stock multiple units

- Competitive Margin: Simple, proven design keeps manufacturing costs stable, supporting healthy wholesale margins

Application Context

This unit is designed for:

- General pneumatic lines: Compressor discharge, main shop supply

- Tool preparation: Ensuring clean, dry, lubricated air for impact wrenches, grinders, sanders, and riveters

- Industrial facilities: Manufacturing, automotive repair, fabrication shops

- Secondary air stations: Support lines for specialized work areas

- OEM integration: Original equipment manufacturers using pneumatic subsystems

The 4000 L/min capacity handles typical shop compressor outputs (5–15 hp range) without significant pressure drop.

Stock this assembly as a core item. It's practical, essential, and has clear resale value to any operation running pneumatic tools.