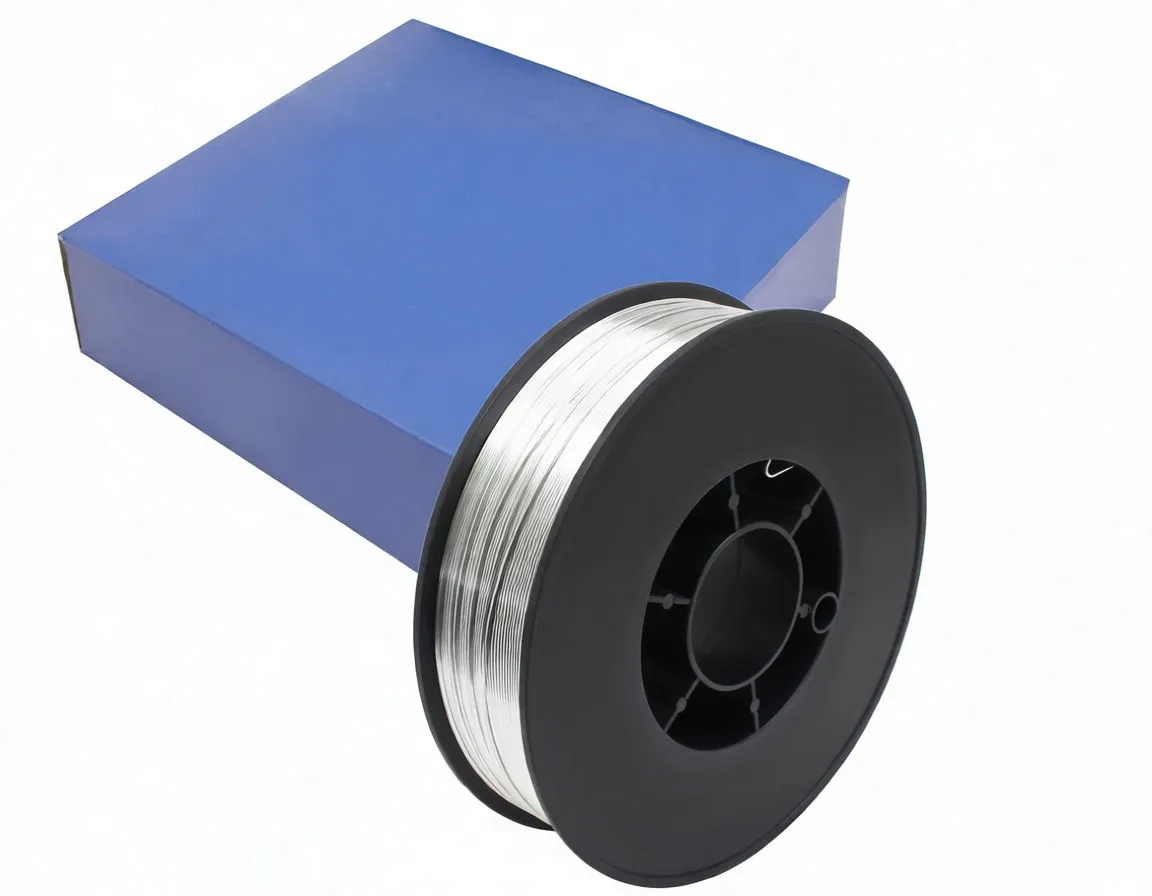

Aluminium Alloy Welding Wire ER4043 + 5% Silicon, 0.8mm–1.2mm Diameter, 2kg Spools

ER4043 aluminium-silicon MIG welding wire for high-strength, corrosion-resistant joints in marine, rail, and automotive fabrication.

Request QuoteDescription

Aluminium Alloy Welding Wire ER4043 + 5% Silicon

Brief Overview

ER4043 is a proven aluminium-silicon MIG welding wire engineered for structural and high-corrosion environments. The 5% silicon content delivers excellent fluidity, superior crack resistance, and high-strength joints across a wide range of aluminium alloys. This wire is the go-to choice for shipbuilding, offshore platforms, railway manufacturing, and automotive assembly operations where reliability cannot be compromised.

For welders requiring maximum versatility, consider complementary options such as TIG rod alternatives in the same alloy composition or higher-magnesium formulations for enhanced corrosion performance.

Key Features

- Silicon-Enhanced Alloy (ER4043): 5% silicon content promotes smooth weld pool flow, reduces hot cracking, and produces high-integrity fusion bonds

- Universal Compatibility: Compatible with 99.99% Argon, Argon/Helium (75/25), or Argon/Helium (50/50) shielding gas mixtures

- Corrosion & Heat Resistance: Delivers excellent performance in marine, offshore, and thermal cycling applications

- Three Diameter Options: Available in 0.8mm, 1.0mm, and 1.2mm—covering precision sheet work through medium-gauge structural welding

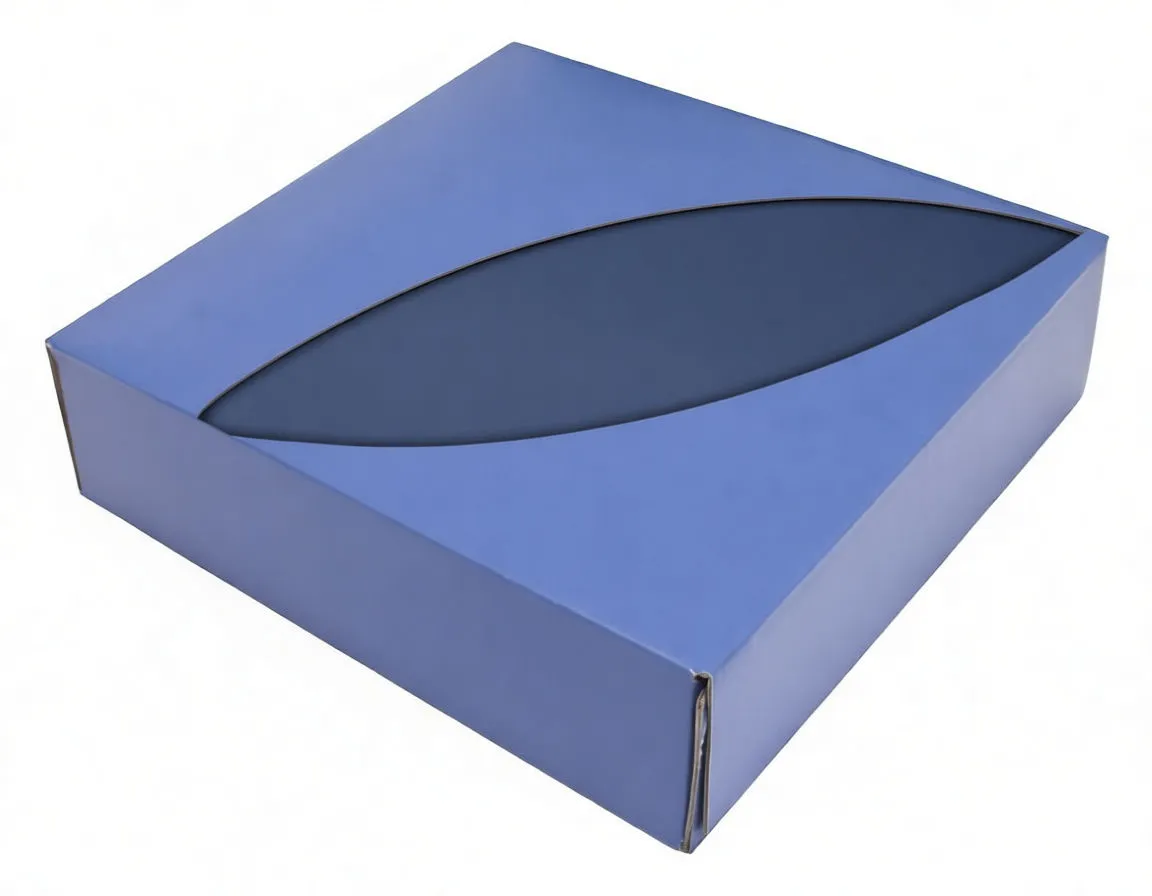

- 2kg Standard Spool: Compact, ready-to-use format optimized for shop inventory and mobile welding rigs

- Anodising-Friendly: Produces white weld metal that integrates seamlessly with anodised finishes—critical for aesthetic and functional surface treatments

Technical Specifications

| Specification | Value |

|---|---|

| Alloy Classification | AWS A5.10 ER4043 |

| Primary Composition | Aluminium + 5% Silicon (balance) |

| Silicon (Si) | 4.5–5.5% |

| Iron (Fe) | 0.80–1.15% |

| Copper (Cu) | 0.05 max % |

| Manganese (Mn) | 0.025 max % |

| Magnesium (Mg) | 0.0035 max % |

| Chromium (Cr) | 0.15 max % |

| Zinc (Zn) | 0.15 max % |

| Titanium (Ti) | 0.15 max % |

| Beryllium (Be) | 0.03 max % |

| Other Elements | 0.50 max % |

| Recommended Shielding Gas | 99.99% Argon; 75% Ar + 25% He; 50% Ar + 50% He |

| Spool Weight | 2 kg |

| Available Diameters | 0.8mm, 1.0mm, 1.2mm |

Available SKUs

| Part Number | Diameter | Spool Weight |

|---|---|---|

| S-M08ER4043 | 0.8mm | 2kg |

| S-M10ER4043 | 1.0mm | 2kg |

| S-M12ER4043 | 1.2mm | 2kg |

Business Advantages for Resellers

- Established Industrial Standard: ER4043 is recognised across marine, aerospace, automotive, and heavy fabrication sectors—your customers already know the name and trust the performance

- Margin-Friendly Multiple Diameters: Three wire sizes allow you to stock a lean, profitable range without excessive inventory complexity

- Bulk-Ready Packaging: 2kg spools are the universal shop format—easy to display, simple to reorder, and compatible with standard MIG torches worldwide

- Cross-Sell Potential: Bundle with TIG rod variants to capture both MIG and TIG welders in your customer base

- Repeat Business: ER4043 is a consumable in high-volume fabrication—expect regular, predictable reorders from maritime yards, rail fabricators, and automotive suppliers

Why ER4043 Over Competitors

ER4043 silicon content (5%) strikes the optimal balance for aluminium-silicon alloys:

- Better Crack Resistance than pure aluminium (ER1100)

- Superior Fluidity compared to magnesium-heavy wires (ER5356)

- Colour Match on Anodised Surfaces — a non-negotiable requirement in marine and automotive cosmetic work

- Proven Track Record in high-stress thermal cycling (ships, locomotives, offshore structures)

Recommendation for Your Shop

Stock all three diameters (0.8mm, 1.0mm, 1.2mm) to serve sheet-metal repair, medium-section fabrication, and structural assembly in a single product line. Pair with a quality argon or argon/helium mix to maximize your welding service revenue.

ER4043 is not a niche product—it is an essential consumable for any professional welding operation that handles aluminium-silicon alloys.