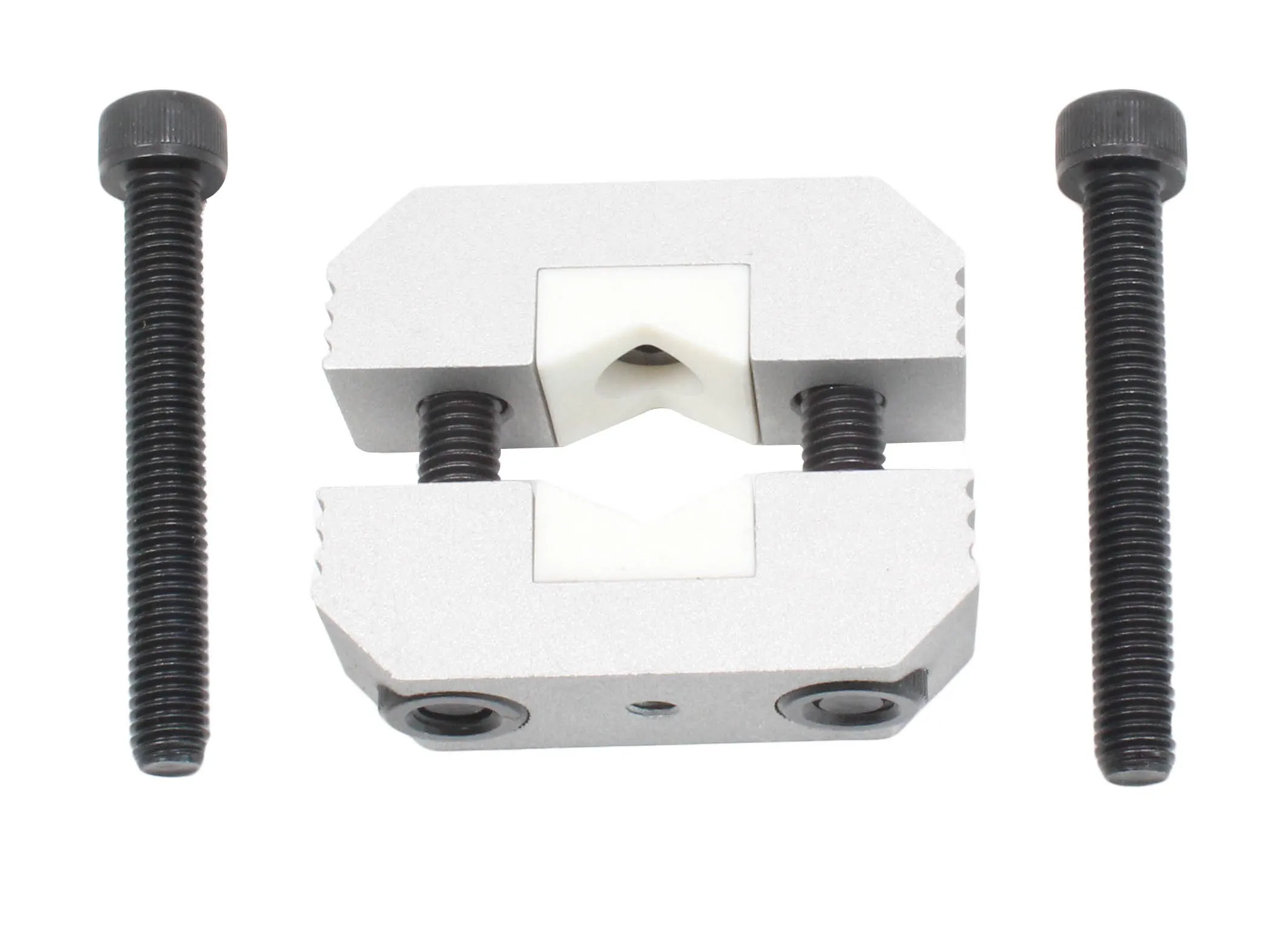

Aluminum Clamp Jaw with V-Block Plastic Inserts and Socket Head Bolts

Precision aluminum clamp jaw with nylon V-inserts for safe shock absorber disassembly and cylindrical workpiece holding.

Request QuoteDescription

Aluminum Clamp Jaw with V-Block Plastic Inserts and Socket Head Bolts

Brief Overview

This aluminum clamp jaw assembly is engineered for controlled disassembly and secure clamping of cylindrical components—particularly shock absorbers—without marring or damaging delicate surfaces. The dual white plastic V-shaped inserts distribute clamping pressure evenly across round work, while the machined aluminum body provides structural rigidity and repeatability. When you need precision without surface damage, this tool delivers. It pairs well with complementary solutions like internal circlip installation tools for complete suspension service workflows.

Key Features

- Dual Plastic V-Inserts: White nylon V-blocks prevent surface marking on painted or finished shock absorber bodies

- Two-Piece Aluminum Construction: Anodized/machined aluminum halves with serrated outer edges for grip stability

- Socket-Head Cap Screws: Internal threaded fasteners draw the jaws together with even, predictable pressure

- Included Fastening Hardware: Two 60mm and two 35mm socket-head cap screws for mounting and assembly

- Machined Precision Surfaces: Stepped cavity design ensures repeatable clamping geometry

Business Advantages for Resellers

This clamp jaw fills a genuine gap in suspension service kits. Shops performing shock absorber work face two choices: risk surface damage with steel vises, or invest in specialized clamping. This tool is the efficient middle ground—affordable to stock, essential for shops wanting to protect customer parts, and justifiable as a line-item upsell during suspension service. Bulk orders support multiple bay setups; the included bolts eliminate first-sale accessory gaps.

Technical Specifications

| Specification | Detail |

|---|---|

| Body Material | Machined Aluminum (Anodized) |

| Jaw Insert Material | Nylon (White Plastic V-Block) |

| Fastening Hardware Included | 2 × 60mm + 2 × 35mm Socket-Head Cap Screws |

| Clamping Type | V-Block (Cylindrical Work) |

| Primary Application | Shock Absorber Disassembly / Cylindrical Clamping |

| Surface Protection | Plastic insert prevents marring |

| Assembly Method | Threaded socket-head cap screws |

Why This Matters to Your Customers

Shock absorber service without proper clamping risks cosmetic and functional damage—a liability no shop wants. The V-block geometry automatically centers round components, reducing operator effort and increasing consistency. The plastic inserts are the key differentiator: they absorb clamping force and distribute it safely, protecting painted or anodized shock bodies that are visible on modern vehicles.

Call to Value

Stock this clamp jaw in bulk to serve shops performing suspension work without defensive equipment investments. Pair it with your existing vise and special tools to create a complete shock service solution. The included fasteners mean immediate usability—no surprises or missing-parts callbacks. Order in quantity to support multi-bay installations or to establish a competitive edge in the suspension service market.