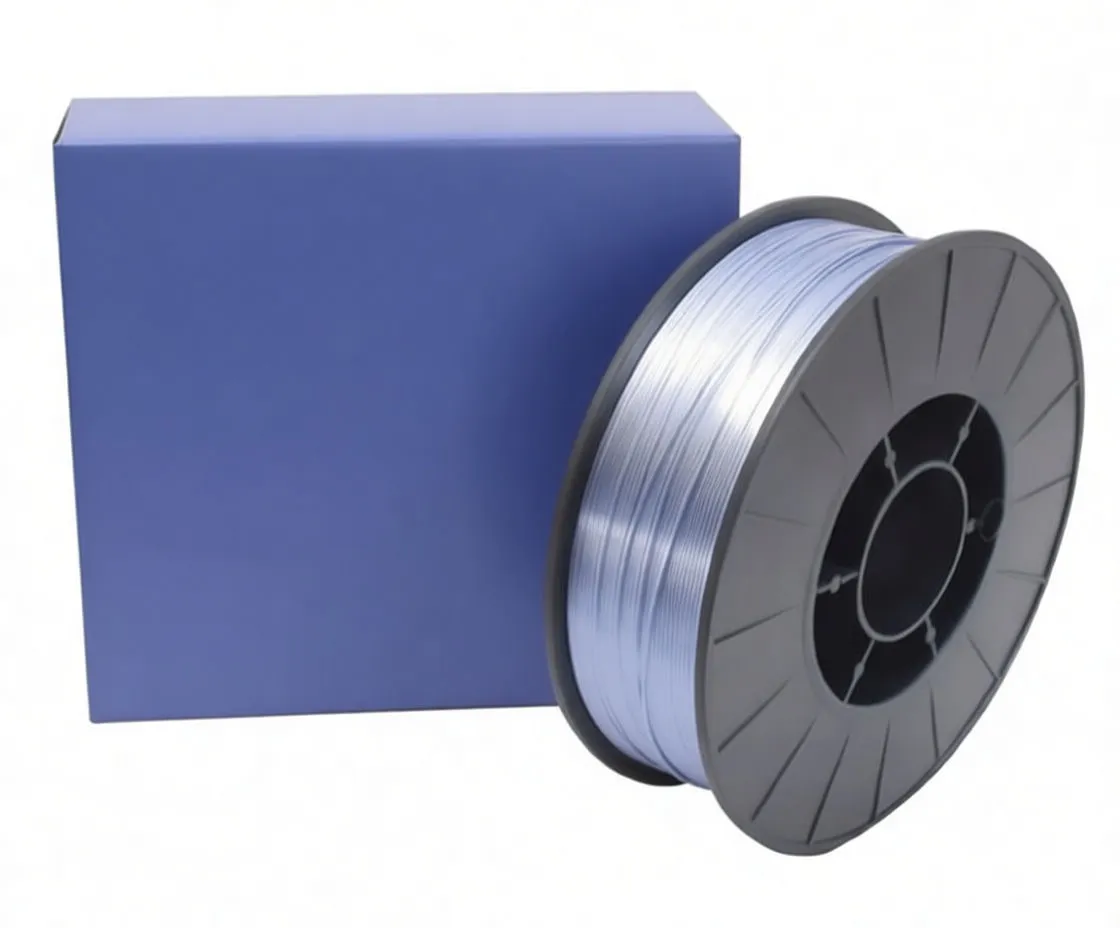

ER5356 Aluminum-Magnesium Alloy Welding Wire, 0.8mm-1.2mm Diameter, 2kg Spool

Premium ER5356 aluminum welding wire for marine, offshore, and rail manufacturing—excellent corrosion resistance and superior crack prevention.

Request QuoteDescription

ER5356 Aluminum-Magnesium Alloy Welding Wire

Brief Overview

ER5356 is a versatile aluminum-magnesium welding wire engineered for demanding industrial applications where corrosion resistance and structural integrity are non-negotiable. This wire delivers exceptional performance in marine environments, offshore platforms, railway manufacturing, and heavy aluminum fabrication. For shops working with thinner aluminum alloys or silicon-free base materials, ER5356 is the preferred choice—and it pairs well with silicon-enhanced aluminum welding alternatives for broader alloy compatibility.

Key Features

- Magnesium-Alloyed Composition: 3.5% magnesium content provides superior strength and corrosion resistance in harsh marine and coastal environments

- Titanium Reinforcement: Small titanium addition (max 0.15%) enhances crack resistance and weld quality

- White Anodized Finish: Post-weld anodizing produces consistent white appearance for excellent color matching on cosmetic applications

- Multi-Gas Compatibility: Works with pure argon (99.99%), argon-helium blends (25% or 50% helium), enabling flexibility across different welding systems

- Three Diameter Options: Available in 0.8mm, 1.0mm, and 1.2mm—covering precision work through heavy structural welds

- 2kg Spool Format: Professional-grade packaging on dedicated reel for controlled feed and minimal waste

Technical Specifications

| Specification | Details |

|---|---|

| Wire Alloy | Aluminum-Magnesium (3.5% Mg) with Titanium |

| AWS Classification | AWS A5.10 ER5356 |

| Available Diameters | 0.8mm, 1.0mm, 1.2mm |

| Spool Weight | 2kg per spool |

| Recommended Shielding Gas | 99.99% Argon; 75% Ar + 25% He; 50% Ar + 50% He |

| Crack Resistance | Excellent—suitable for critical stress-bearing joints |

| Corrosion Resistance | Superior in saltwater and chemical exposure |

| Post-Weld Color | White (excellent anodizing match) |

Chemical Composition (%)

- Magnesium: 3.0–3.5

- Silicon: 0.06–0.15

- Iron: 1.40–1.85

- Copper: 0.80–1.15

- Chromium: Max 0.15

- Zinc: Max 0.15

- Titanium: Max 0.15

- Beryllium: Max 0.03

- Manganese: Max 0.025

- Aluminum: Balance

Business Advantages for Resellers

- Market Demand: ER5356 is essential stock for any shop handling marine, offshore, or precision aluminum work. These are non-discretionary purchases for fabricators working with non-silicon aluminum alloys.

- Margin Opportunity: Welding consumables maintain steady turnover with predictable reorder cycles. Multiple diameter options allow you to upsell based on customer application.

- Professional Positioning: Stocking AWS-certified ER5356 signals to your customer base that you support critical infrastructure work—shipbuilding, platform fabrication, rail manufacturing.

- Complementary Selling: Pair with silicon-based aluminum welding wire to serve the full spectrum of aluminum alloy requirements and increase basket value.

- Low Inventory Risk: 2kg spools are manageable stock sizes with long shelf life (proper storage conditions) and consistent demand from repeat customers.

Applications

- Marine Fabrication: Hull repairs, seawater-exposed structural welding

- Offshore Platforms: Corrosion-critical joints in salt spray environments

- Railway & Locomotive Manufacturing: Lightweight structural components requiring high strength and crack resistance

- Automotive Aluminum Frames: Body panels and structural supports where appearance matters post-anodizing

- Pressure Vessel Welding: Non-ferrous applications requiring superior ductility and fatigue resistance

Technical Notes

ER5356 is optimized for aluminum alloys without significant silicon content (5xxx and 6xxx series base metals). The magnesium addition creates stronger, more ductile welds than pure aluminum wire (ER1100), while the titanium element suppresses hot cracking—a critical advantage in thicker sections or restrained joints.

For shops transitioning between ER5356 (magnesium-based) and silicon-enhanced alternatives, ensure your gas system and machine parameters are adjusted accordingly. The white anodized appearance is a significant selling point for cosmetic or visible fabrications where color consistency is contractual.

Stock ER5356 in all three diameters to maximize application coverage and customer retention. This is essential consumable inventory for any professional aluminum welding operation.