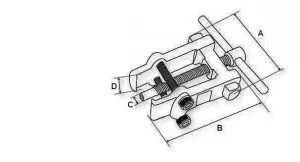

Armature Bearing Puller, 35-80mm Adjustment Range, Hardened Steel with Lock Arms

Professional-grade armature bearing puller for alternators and windshield wiper mechanisms. Hardened steel construction with adjustable jaw range.

Request QuoteDescription

Armature Bearing Puller, 35-80mm Adjustment Range

Brief Overview

This armature bearing puller is engineered for precise extraction of small bearings in alternators, starter motors, and windshield wiper assemblies. Built from hardened steel with lock arms that secure the bearing during the pulling process, it delivers the mechanical advantage needed for controlled, damage-free removal. The adjustable jaw range accommodates bearings from 35mm to 80mm diameter, making it an essential tool for electrical component servicing. Complement your pulling toolkit with a universal bearing extractor set for broader workshop coverage.

Key Features

- Hardened Steel Construction: Resists deformation under high extraction forces; maintains precision over thousands of cycles

- Lock Arm Design: Prevents jaw slip during pulling; critical for bearings in tight alternator housings

- 35-80mm Adjustment Range: Covers most alternator and starter motor bearing sizes

- Central Threaded Forcing Screw: T-handle mechanism for controlled, progressive force application

- Removable Jaw Tips: Allows swapping or replacing contact points; extends tool lifespan

- Compact Footprint: Fits into engine bays and cramped electrical component housings

- Included Hex Key Accessory: For jaw adjustment and maintenance

Business Advantages for Resellers

- High Demand in Alternator/Starter Service: Electrical repairs are a recurring revenue stream; this tool is essential for any shop offering charging-system diagnostics

- Durability for High-Volume Use: Hardened steel arms withstand repeated extraction cycles without fatigue or loosening

- Low Breakage Rate: Proper jaw design reduces risk of bearing damage, protecting your shop's reputation and reducing comebacks

- Affordable Inventory: Low cost per unit with strong margin potential for bulk orders

- Standardized Size Range: The 35-80mm span covers 90% of common alternators and starter motors across European and global platforms

Technical Specifications

| Specification | Value |

|---|---|

| Jaw Adjustment Range | 35–80mm |

| Material | Hardened Steel (Black Oxide Finish) |

| Forcing Mechanism | Threaded Screw with T-Handle |

| Jaw Type | Removable Tips with Lock Arms |

| Accessories Included | Hex Key (Allen Wrench) |

| Application | Alternators, Starter Motors, Windshield Wiper Arms |

| Finish | Black Oxide (Corrosion Resistant) |

Why Professionals Choose This Tool

When a bearing seizes in an alternator, brute force will damage the component. This puller's lock arm design and progressive forcing screw ensure smooth extraction without distortion. Mechanics appreciate the compact design—it fits where impact tools cannot. The hardened steel construction guarantees consistent performance across thousands of jobs, making it a workhorse for any electrical repair operation.

Reseller Value Proposition

Stock this tool to capture margin on every charging-system overhaul in your customer base. The 35-80mm range handles the majority of compact alternators and starters, reducing the need for multiple SKUs. Bundle it with specialized steering and bearing extraction systems to position your shop as a complete mechanical solution provider.

Recommended Order Volume: Minimum 5–10 units per location for active service departments. Higher volumes unlock wholesale pricing and ensure stock availability during seasonal repair peaks.