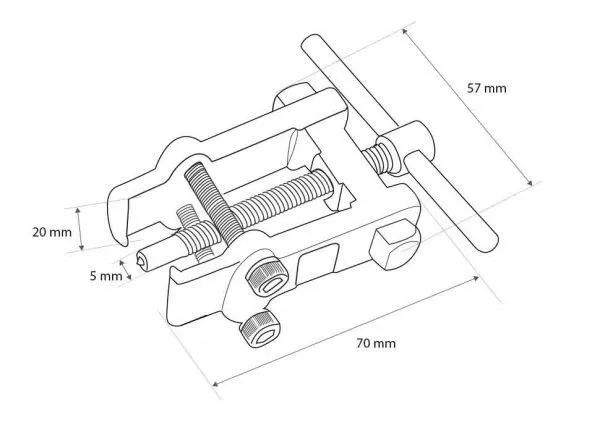

Armature Bearing Puller, Hardened Steel with Lock Arms and T-Handle

Compact hardened steel bearing puller designed for alternator and windshield wiper arm removal, featuring dual locating pins and central forcing screw.

Request QuoteDescription

Armature Bearing Puller – Professional-Grade Bearing Extraction Tool

Overview

This armature bearing puller is a precision-engineered tool designed specifically for the controlled extraction of small bearings from automotive alternators and windshield wiper mechanisms. Constructed from hardened forged steel with a dark matte protective finish, it delivers reliable, damage-free bearing removal in confined spaces where standard pullers cannot operate. The dual-arm design with integrated lock pins ensures positive engagement without slippage, while the central threaded forcing screw provides controlled, gradual extraction pressure.

For shops requiring a broader extraction capability, consider pairing this tool with a universal bearing puller set for comprehensive workshop coverage.

Key Features

- Hardened forged steel construction – Resistant to deformation under sustained extraction pressure

- Dual U-shaped arms with lock pins – Secure engagement on small bearing races without cam-out or bearing damage

- Adjustable locating bolts – Accommodate varying bearing sizes and configurations

- Central forcing screw with T-handle – Provides smooth, controlled extraction without shock load

- Compact footprint – Operates in tight alternator and wiper motor assemblies where full-size pullers cannot fit

- Included hex key – For adjusting locating pins and side bolts

- Dark finished steel – Corrosion-resistant protective coating

Technical Specifications

| Specification | Value |

|---|---|

| Material | Hardened forged steel |

| Overall length | ~70 mm |

| T-handle width | ~57 mm |

| Jaw depth | 20 mm |

| Central pin diameter | 5 mm |

| Finish | Dark matte (corrosion-resistant) |

| Included accessories | Hex key for adjustment |

| Application | Alternator bearings, windshield wiper motor bearings |

Business Advantages for Resellers

- High-frequency demand – Alternator and wiper motor service is recurring maintenance across all vehicle segments

- Minimal competition in specialized segment – Few suppliers stock compact bearing pullers; positions your shop as a complete service resource

- Repeatable margin opportunity – Cost-effective unit cost supports healthy retail markup while remaining competitive

- No consumables required – One-time sale with exceptional durability; customers rarely need replacement

- Bundling potential – Pairs naturally with alternator test kits and wiper blade assemblies for cross-sell opportunities

- Professional credibility – Offering specialized extraction tools elevates your shop's perceived expertise and service capability

Application Context

This tool addresses the specific challenge of alternator bearing removal without risk of seal or race damage. The compact design fits between alternator body components, and the dual-pin engagement ensures even load distribution. Similarly, windshield wiper motor assembly work—particularly on trucks and commercial vehicles—frequently requires safe bearing extraction in tight quarters where leverage is limited.

The hardened steel construction withstands repeated use across high-volume service shops, making it a genuine long-term investment rather than a consumable item.

Recommended for: Professional automotive shops, fleet maintenance facilities, truck and commercial vehicle service centers, and alternator/wiper motor specialists.