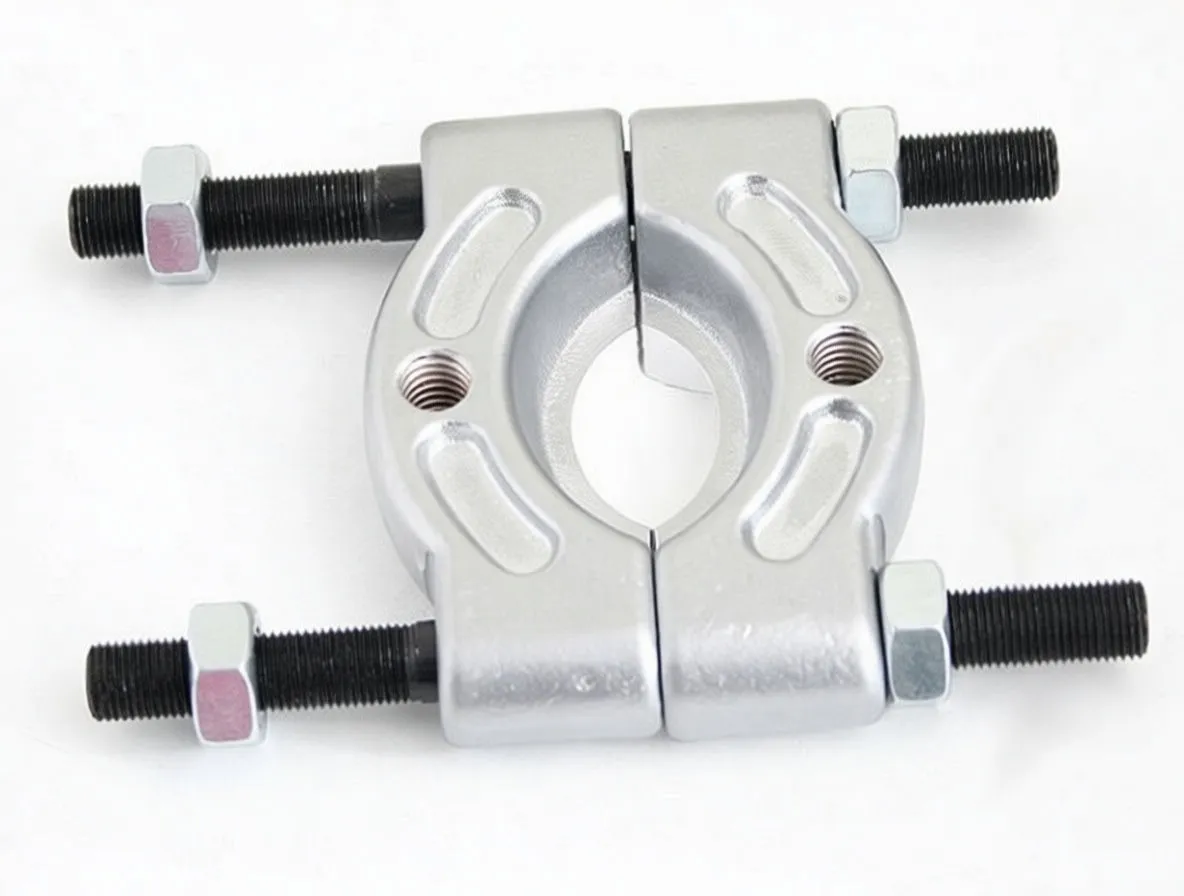

Bearing Separator 30-50 mm, Forged Steel with Threaded Rods and Hex Nuts

Professional-grade bearing separator for 30-50 mm applications. Forged steel construction with split-ring design and threaded rod clamping for safe, controlled extraction.

Request QuoteDescription

Bearing Separator 30-50 mm, Forged Steel with Threaded Rods and Hex Nuts

Brief Overview

This bearing separator is engineered for technicians and workshops that regularly handle pressed-on bearings, gears, and bushes in the 30-50 mm range. The two-piece forged steel design splits cleanly around the bearing race, allowing safe extraction from shafts and bolts without damage to the component. The threaded rod assembly provides consistent, controlled clamping force—a critical advantage when removing expensive bearings where precision matters. Combine this tool with a smaller-capacity separator set to cover a broader size range, or pair it with a complete gear extraction system for comprehensive shaft work across multiple applications.

Key Features

- Forged Steel Construction – Hard-wearing, impact-resistant material engineered for prolonged shop use without degradation

- Machined Jaws – Precision-ground inner surfaces that cradle bearings securely and prevent slipping during extraction

- Split-Ring Design – Two halves allow the separator to wrap tightly around the bearing without requiring full shaft disassembly

- Threaded Rod Assembly – Dual black threaded rods with hex nuts deliver uniform, controlled clamping pressure

- Tapped Mounting Holes – Threaded holes enable attachment of hydraulic or mechanical pullers for flexible extraction methods

- 30-50 mm Capacity – Covers the most common bearing sizes in automotive, industrial, and equipment repair operations

Business Advantages for Resellers

- High-Demand Core Tool – Every bearing removal job in this size range requires a separator; this capacity covers the majority of practical shop applications

- Durable Investment – Forged steel construction means minimal replacement costs and strong customer retention; reduced warranty claims and repeat orders

- Compact Footprint – Occupies minimal shelf space while delivering professional-grade capability; ideal for space-constrained retail environments

- No Consumable Parts – One-time sale with genuine long-term durability; excellent margin on a tool that doesn't require replacement

- Cross-Sell Potential – Position alongside puller sets, extension kits, and universal removal tools to increase average transaction value and customer lifetime value

Technical Specifications

| Specification | Detail |

|---|---|

| Bearing Capacity | 30–50 mm bore diameter |

| Material | Forged steel, machined jaws |

| Assembly | Two-piece split design with dual threaded rods |

| Fastening | Hex nuts on threaded rods for clamping force |

| Mounting | Tapped holes for puller attachment |

| Finish | Silver metallic, corrosion-resistant plated steel |

| Weight | Approximately 1.5–2 kg (compact, hand-portable) |

Real-World Applications

This separator is essential for:

- Removing pressed-on wheel bearings during brake service or hub assembly

- Extracting internal gears from drive shafts in industrial gearboxes

- Removing bushes and spacers without damaging bore tolerances or races

- Automotive transmission work, differential bearing removal, and equipment maintenance

The threaded rod design accommodates both hydraulic press and hand puller approaches, giving technicians flexibility in their extraction method based on available shop equipment.

Why Stock This Product

A bearing separator in the 30-50 mm range is a workhorse tool in any professional shop. It eliminates guesswork and risk when handling expensive bearings and shafts—components that, if damaged during extraction, represent significant cost to your customer. Stock depth in this size translates directly to repeat customer visits and workshop loyalty. Technicians expect this size to be on hand, and they'll move to another supplier if availability is uncertain.

Ready to order? Add this bearing separator to your inventory today and position it alongside complementary extraction tools to maximize customer value and shop productivity.