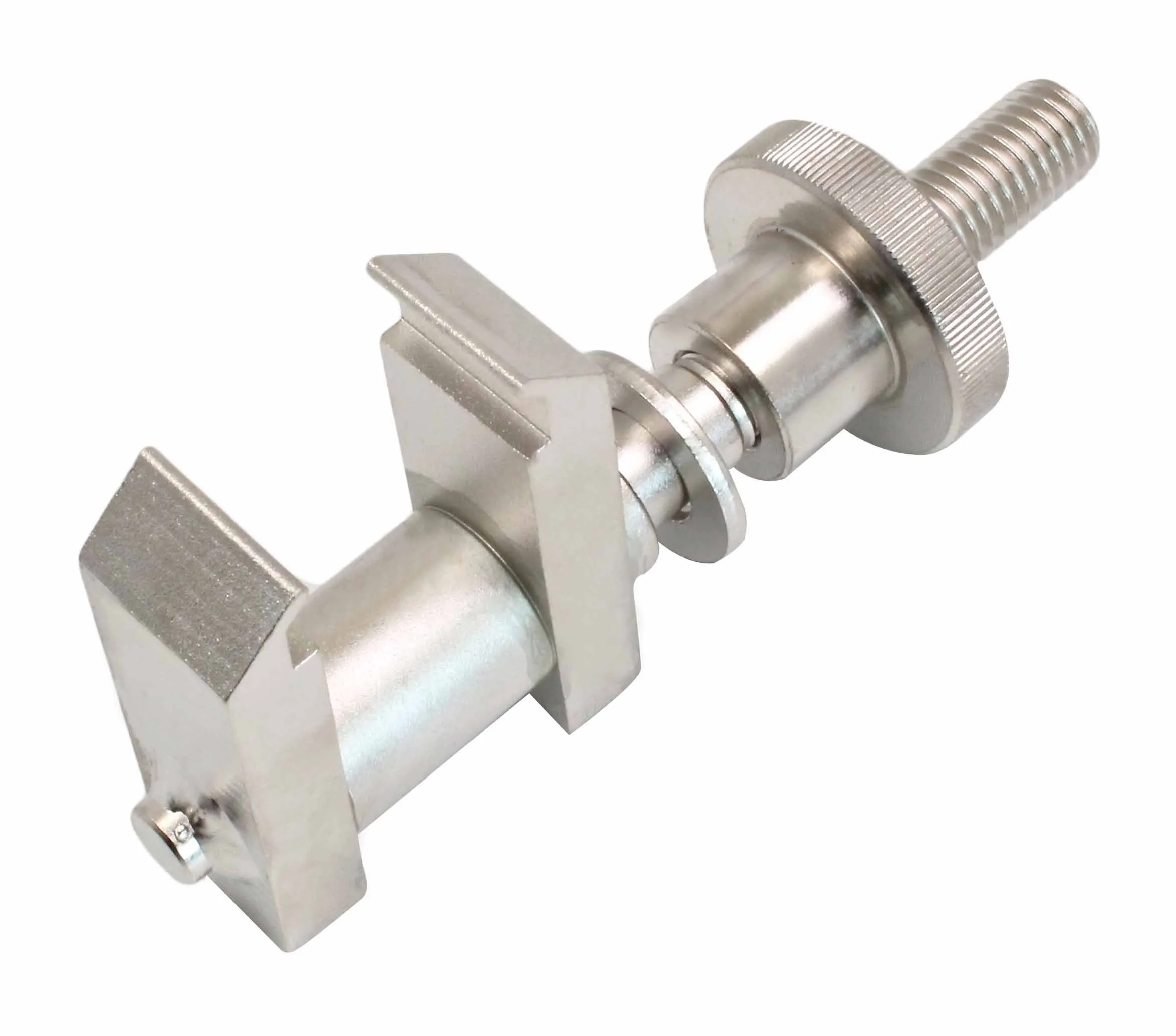

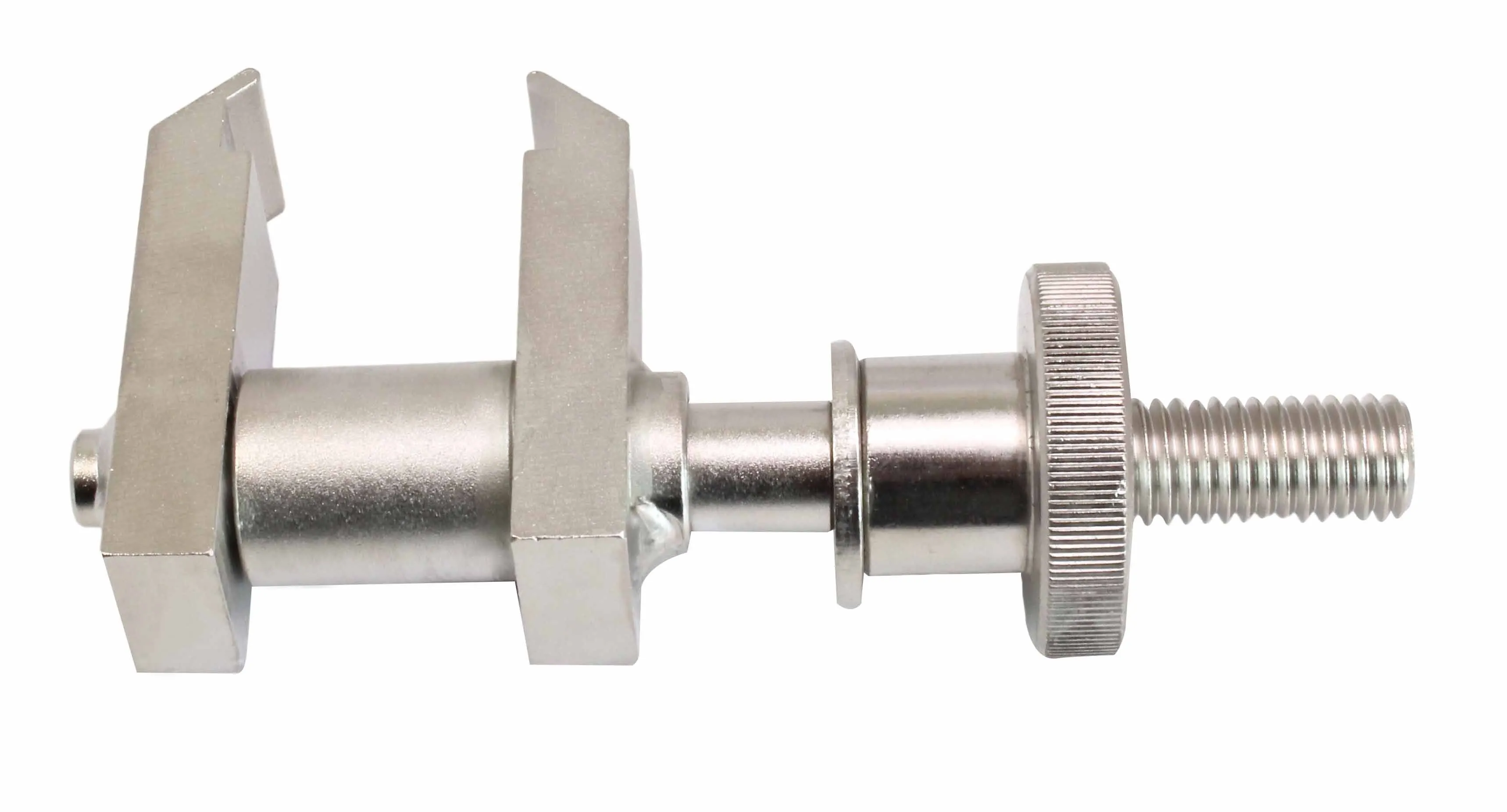

BMW/Opel Vauxhall Camshaft Gear Alignment Tool with Spring Mechanism

Precision camshaft gear alignment tool for BMW, Opel, and Vauxhall diesel engines—essential for accurate sprocket positioning during cam removal and installation.

Request QuoteDescription

BMW/Opel Vauxhall Camshaft Gear Alignment Tool with Spring Mechanism

Brief Overview

This is a specialist-grade camshaft gear alignment tool designed specifically for split-gear sprocket systems on modern BMW, Opel, Vauxhall, and MINI diesel engines. The tool aligns the two halves of the camshaft sprocket with precision, eliminating guesswork during camshaft removal and installation. Built with machined fork jaws and a spring-loaded mechanism, it ensures repeatable, damage-free alignment—critical for shops handling timing-sensitive diesel engines. For shops managing broader timing system work, pairing this with a comprehensive BMW timing tool set or an Opel/Vauxhall timing chain solution rounds out your diesel engine service capabilities.

Key Features

- Dual Fork-Jaw Design: Machined rectangular jaws with squared internal notches grip both halves of the split sprocket simultaneously, preventing misalignment during installation

- Spring-Loaded Mechanism: Built-in spring tension maintains consistent pressure between gear halves, reducing installation errors and protecting against tooth damage

- Threaded Adjustment Stud: Knurled thumb nut allows precise, controlled engagement—no guesswork on tightening force

- Machined Zinc/Chrome-Plated Finish: Corrosion-resistant metallic coating ensures tool longevity in workshop environments; precision-cut edges prevent gear slipping

- Compact Single-Unit Construction: Integrated barrel spacer and locating pin keep the tool portable and straightforward to use—no loose components to manage

Real-World Application

This tool eliminates one of the most time-consuming aspects of diesel engine timing work: aligning split camshaft gears by hand or using makeshift methods. On Opel Corsa E 1.3D, BMW 1-Series/2-Series/X1 1.5D, and MINI One 5D diesel engines, improper gear alignment can lead to:

- Tooth cam-out and permanent gear damage (costly replacement)

- Timing variance that causes rough idle, poor cold start, or diagnostic trouble codes

- Extended labor time due to repeated removal/reinstallation attempts

This tool delivers alignment in a single, repeatable operation. Technicians can confidently install camshafts knowing the sprocket halves are correctly positioned—reducing comebacks and building customer confidence in your diesel service quality.

Business Advantages for Resellers

- High-Margin Specialized Tool: Diesel engine timing work commands premium labor rates; shops will buy this to justify faster, cleaner jobs

- Targeted Market: Direct fit for popular diesel platforms (Opel Corsa E, BMW 1-Series/2-Series, MINI). Steady demand from independent diesel specialists

- Reduces Technician Frustration: Eliminates manual alignment guesswork. Shops will reorder for team consistency

- Bundling Opportunity: Position alongside valve cover gaskets, timing components, or comprehensive diesel engine service kits to increase basket size

- Professional Credibility: Offering specialized tools like this signals expertise to customers—builds loyalty and attracts shops seeking trusted suppliers

Technical Specifications

| Specification | Detail |

|---|---|

| Application | Opel/Vauxhall Corsa E 1.3D (2015–); BMW 1-Series, 2-Series, X1 1.5D (2014–2015+); MINI One 5D (2014–) |

| Compatible Engines | LKU/B13DTE, LKU/B13DTR, LKV/B13DTC (Opel/Vauxhall); B37 C15A, B367 D15A (BMW/MINI) |

| Primary Function | Aligns split camshaft sprocket halves; facilitates safe removal and installation |

| Mechanism | Spring-loaded fork-jaw design with threaded adjustment stud |

| Material | Machined steel with zinc/chrome-plated finish |

| Components | Two opposing jaw blocks, central cylindrical spacer, threaded stud, knurled adjustment nut, locating pin, retaining washer |

| Finish | Precision-machined metallic coating (corrosion-resistant) |

| Assembly | Single integrated unit; no loose parts |

Why This Matters for Your Customers

Diesel engine timing work is precise, unforgiving work. A single misalignment can mean:

- Wasted labor (reinstalling the same camshaft 2–3 times)

- Damaged sprocket teeth (new parts required)

- Customer dissatisfaction and potential warranty claims

This tool eliminates those risks by delivering repeatable, controlled alignment every time. For independent shops and diesel specialists, it's not an optional accessory—it's a time-saver and liability reducer that pays for itself on the second or third use.

Call to Value

Stock this tool as a must-have for any shop servicing modern Opel, Vauxhall, BMW, or MINI diesel engines. It's a low-volume, high-confidence product that builds your reputation as a serious diesel service supplier. Resellers can position it confidently to workshops seeking premium, specialized tooling that simplifies complex timing work.