Universal Brake Pipe Flaring Tool for SAE and DIN Standards, 3/16-Inch

Compact, portable flaring tool for precision brake pipe flares on-vehicle. Creates SAE and DIN convex flares in steel, copper, brass, and aluminum tubing.

Request QuoteDescription

Universal Brake Pipe Flaring Tool for SAE and DIN Standards

Brief Overview

This universal brake pipe flaring tool delivers professional-grade flaring capability in a compact, portable package—ideal for technicians working on brake systems with pipes still attached to the vehicle. Unlike stationary bench equipment, its lightweight design and small footprint make it the go-to choice for on-car repairs where space and accessibility are critical. It produces precise, code-compliant SAE and DIN convex flares on steel, copper, brass, and aluminum tubing. Pair this with a precision pipe cutter to offer customers a complete brake line preparation system, or recommend a hydraulic-powered alternative for shops handling high-volume brake work.

Key Features

- SAE and DIN Capability: Produces both single male and double female flares to meet international brake system standards

- Universal Material Compatibility: Works on steel, copper, brass, and aluminum brake tubing

- Compact and Lightweight Design: Engineered for on-vehicle access where larger equipment cannot fit

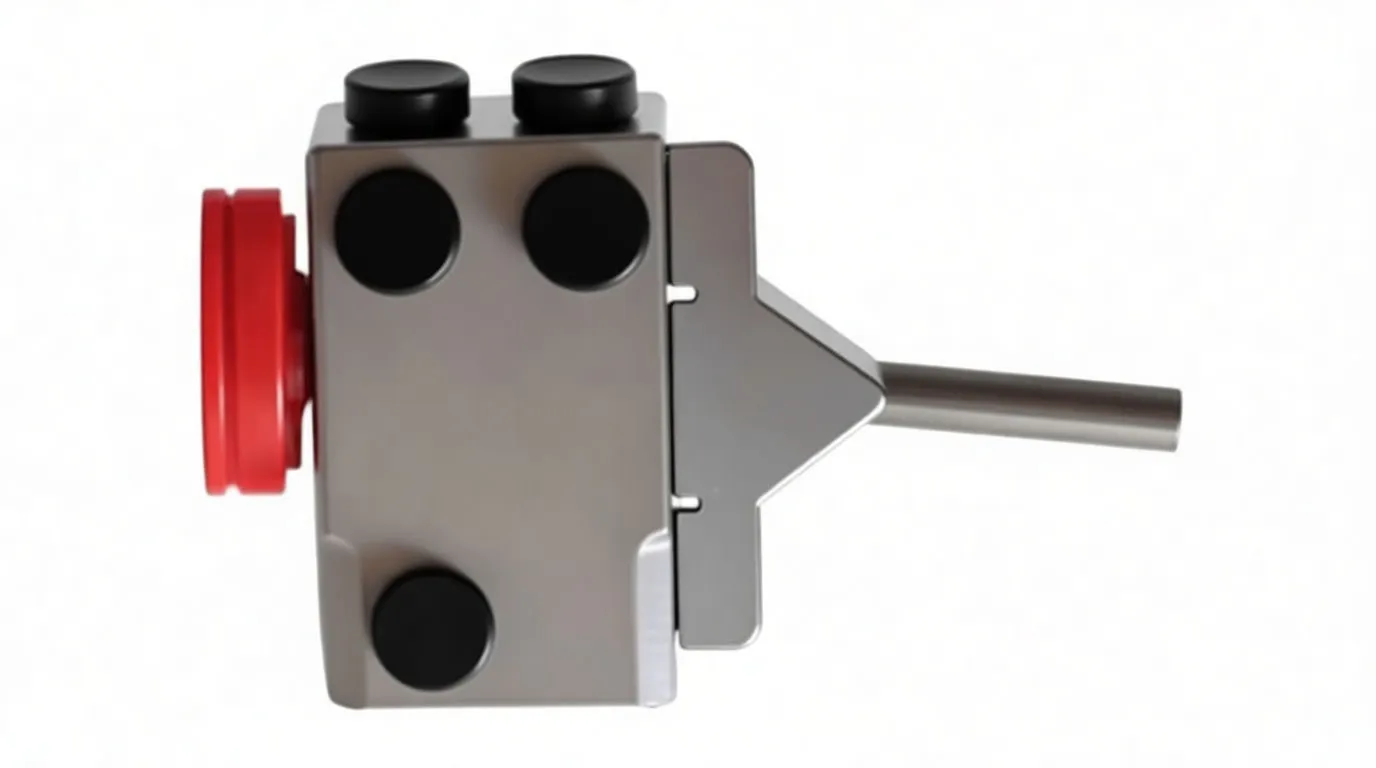

- Precision Machined Block: Split two-piece steel flaring block with accurately machined die faces for consistent, repeatable flares

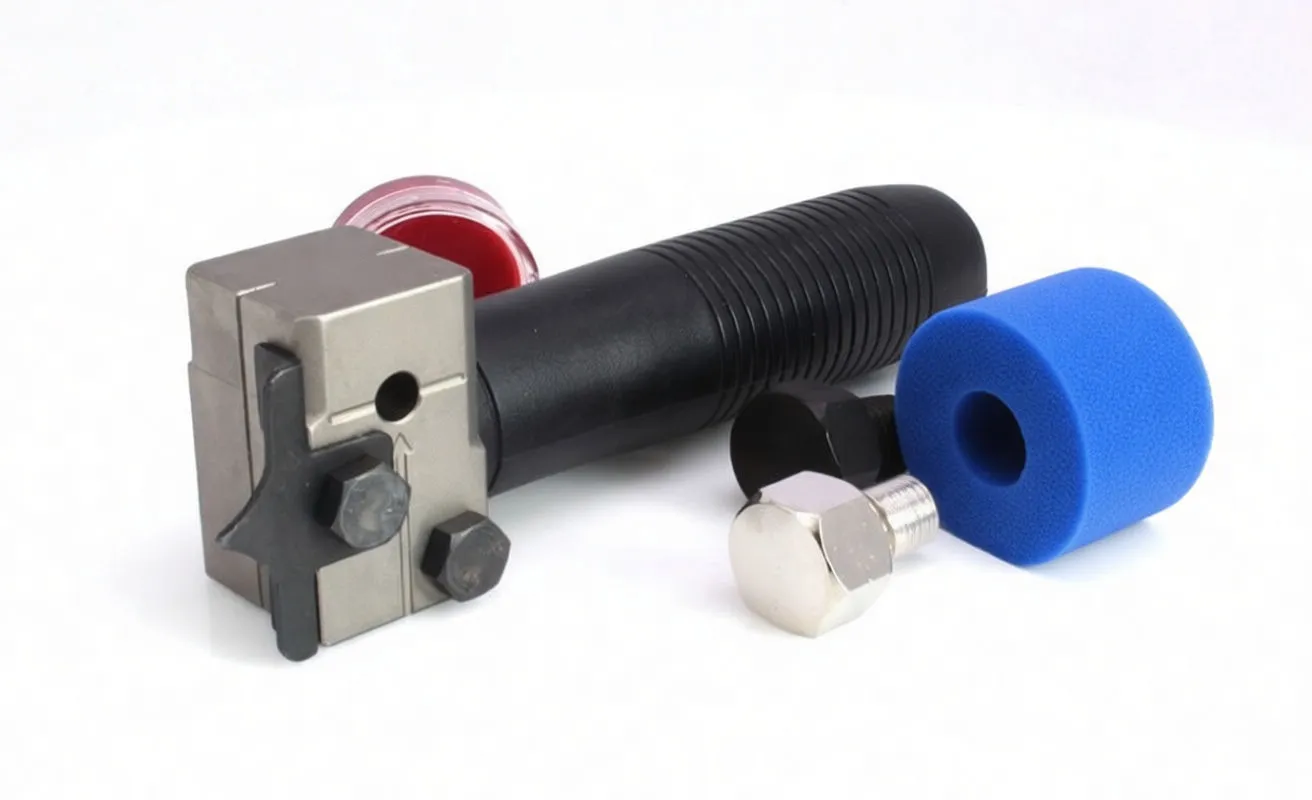

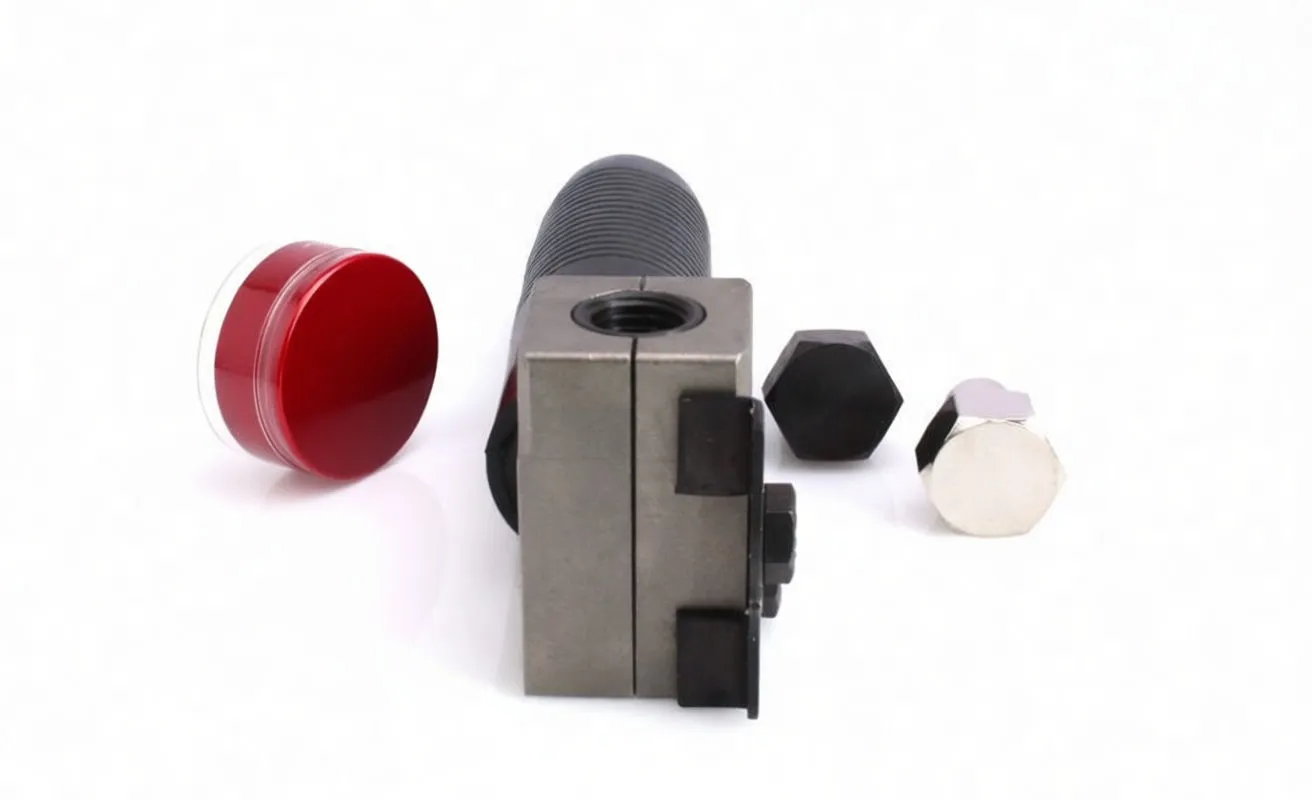

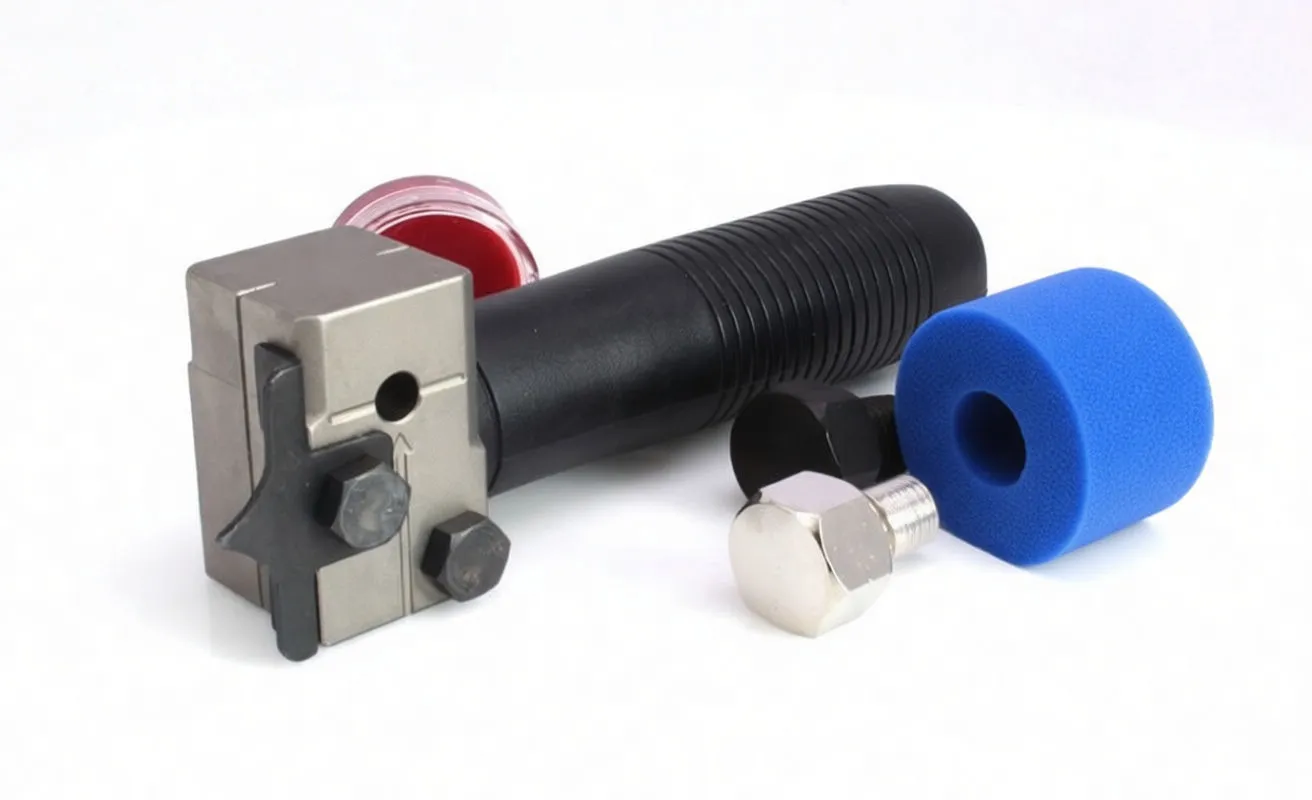

- Complete Kit Included: Threaded punch screw, hex adapter pieces, star-shaped clamp plate, and special punch grease

- Quick Setup: Minimal assembly required; operator can begin flaring within seconds of installation

Why Resellers Choose This Tool

Stock Depth & Turnover: Brake pipe flaring tools remain in steady demand across independent shops, fleet maintenance, and mobile technicians. This universal design captures both SAE and DIN market segments with a single SKU, reducing inventory complexity while maximizing shelf coverage.

Margin & Accessibility: Lighter weight than hydraulic flaring kits and no power source required—resellers can offer entry-level brake shops an affordable gateway product. Customers often buy the manual tool first, then upgrade to hydraulic models for higher throughput, creating natural upsell opportunities.

Professional Credibility: Portable flaring tools signal that a shop can handle emergency brake repairs on-site. Resellers who stock this tool position themselves as a one-stop supplier for brake system diagnostics and repair—critical for maintaining customer loyalty in competitive markets.

Technical Specifications

| Specification | Detail |

|---|---|

| Tubing Size | 3/16-inch (4.75 mm) |

| Flare Standards | SAE Convex and DIN Convex |

| Flare Types | Single male and double female |

| Compatible Materials | Steel, copper, brass, aluminum |

| Block Construction | Split two-piece machined steel |

| Handle Material | Black ribbed plastic |

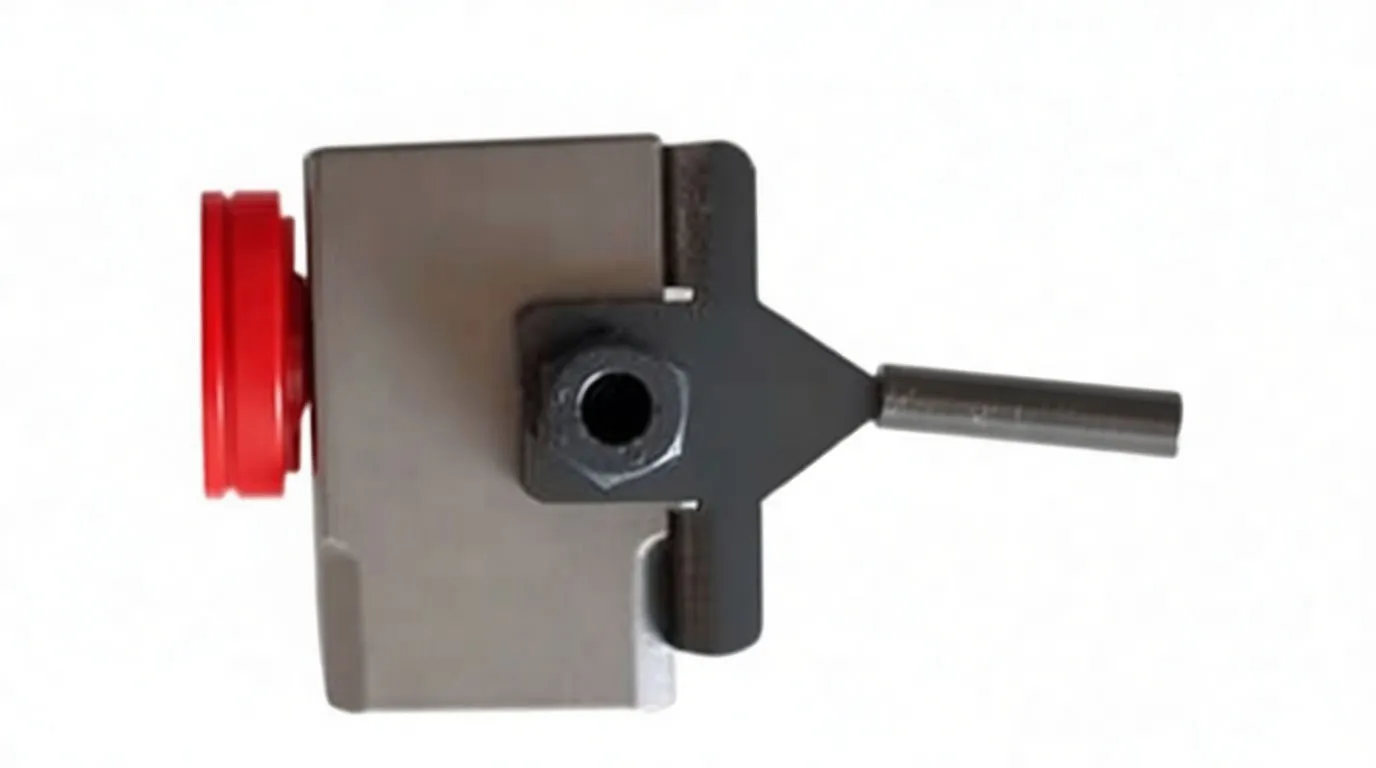

| Clamping Mechanism | Star-shaped clamp plate with hex bolts |

| Included Accessories | Threaded punch screw, adapter hex pieces, special punch grease |

| Portability | Lightweight; designed for on-vehicle access |

How It Works

The tool clamps the brake pipe securely in the split flaring block using the star-shaped clamp plate and hex bolts. The threaded punch screw is inserted into the machined hole and rotated to form the flare, with the punch geometry creating either SAE or DIN convex profile depending on the die face orientation. The included special punch grease reduces friction and ensures clean, repeatable flares with minimal operator effort.

Bottom Line

For resellers targeting independent shops and mobile technicians, this universal brake pipe flaring tool fills a critical niche: it's affordable, portable, and versatile enough to handle both SAE and DIN standards without requiring different models. Stock it confidently—your customers will use it repeatedly, and the natural upgrade path to hydraulic or multi-size tools keeps them returning for expansion purchases.