Composite Air Impact Wrench, 3/4-Inch Square Drive, Twin Hammer, 2000 Nm Torque

Heavy-duty 3/4-inch pneumatic impact wrench with twin hammer system, 2000 Nm capacity, and composite housing. Ideal for industrial fastening and heavy assembly work.

Request QuoteDescription

Composite Air Impact Wrench, 3/4-Inch Square Drive, Twin Hammer, 2000 Nm Torque

Brief Overview

This 3/4-inch square drive pneumatic impact wrench delivers professional-grade power in a lightweight package, engineered for demanding heavy industrial applications. The twin hammer system provides consistent torque output across sustained use, while the composite housing keeps weight at just 5.5 kg—critical for operator fatigue reduction during long shifts. For shops requiring high power at multiple drive sizes, complementary options include smaller drive pneumatic impact tools for general automotive work.

Key Features

- 3/4-Inch Square Drive: Direct compatibility with industrial-grade sockets for heavy fastening, assembly, and disassembly tasks

- Twin Hammer Mechanism: Dual hammer system ensures consistent torque delivery and reduced shock to the tool and fastener

- 2000 Nm Maximum Torque: Handles the largest fastening jobs—camshaft bolts, transmission work, industrial equipment assembly

- Composite Housing: Durable polymer construction resists impact damage and reduces overall weight without compromising durability

- Right/Left Rotation Switch: Bidirectional operation for both tightening and loosening applications

- 3-Level Power Reduction: Adjustable power settings allow fine control—full power for breaking loose, reduced power for final tightening to prevent over-torquing

- 4200 RPM Free Speed: High-speed rotation for quick fastener engagement, reducing cycle time

- Ergonomic Design: Auxiliary side handle (shown in images) provides stable two-handed control and reduces wrist strain

- Bottom-Mounted Air Exhaust: Directs exhaust downward and away from the operator's face

- Hardened Steel Internals: Rotor, back plate, and front plate manufactured from special hardened steel for extended service life under high-torque loads

Specifications

| Specification | Value |

|---|---|

| Square Drive Size | 3/4 inch (19 mm) |

| Maximum Torque | 2000 Nm |

| Free Speed | 4200 RPM |

| Hammer Type | Twin Hammer |

| Power Reduction Levels | 3 settings |

| Weight | 5.5 kg |

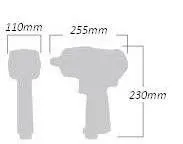

| Overall Length | 255 mm |

| Overall Height | 230 mm |

| Overall Width | 110 mm |

| Maximum Socket Capacity | 30 mm |

| Rotation | Bidirectional (Right/Left switch) |

| Housing Material | Composite (impact-resistant polymer) |

| Internal Components | Hardened steel rotor, plates |

| Air Outlet Position | Bottom of handle |

Business Advantages for Resellers

High Demand Segment: 3/4-inch impact wrenches command premium margins in heavy industrial, fleet maintenance, and manufacturing sectors. This power class attracts professional buyers who will not compromise on tool quality.

Margin Opportunity: The 2000 Nm capacity positions this tool in the premium pricing tier. Customers in heavy assembly, transmission work, and industrial equipment service expect to pay accordingly for reliability.

Differentiation: Twin hammer design is preferred by professional technicians over single-hammer equivalents—they recognize the consistency and reduced wear. This is a selling point that justifies bulk orders.

Low Return Risk: Composite housing + hardened steel internals = durability that reduces warranty claims. Pneumatic tools typically have lower failure rates than electric equivalents, improving your reputation with customers.

Complementary Sales: Stock this alongside 1/2-inch twin hammer alternatives to offer customers a full drive-size range. Mixed SKU orders increase average transaction value.

Technical Rationale

The 3/4-inch square drive targets applications where 1/2-inch tools lack sufficient power:

- Heavy truck and bus maintenance (suspension, drivetrain)

- Industrial equipment assembly and maintenance

- Agricultural machinery service

- Large marine engine work

- Manufacturing/production line fastening

The 5.5 kg weight keeps this tool practical for sustained hand-held use—critical in professional environments where operator fatigue directly impacts productivity. The three-level power reduction prevents the common problem of over-torquing large fasteners during final tightening, reducing stripped bolt complaints from your customer base.

Bottom Line

This is a professional-grade tool for shops that have moved beyond entry-level equipment. Stock it confidently—the 2000 Nm capacity and proven twin hammer design make it a standard specification in heavy industrial maintenance. Position it as the natural upgrade path for customers currently using smaller drives.