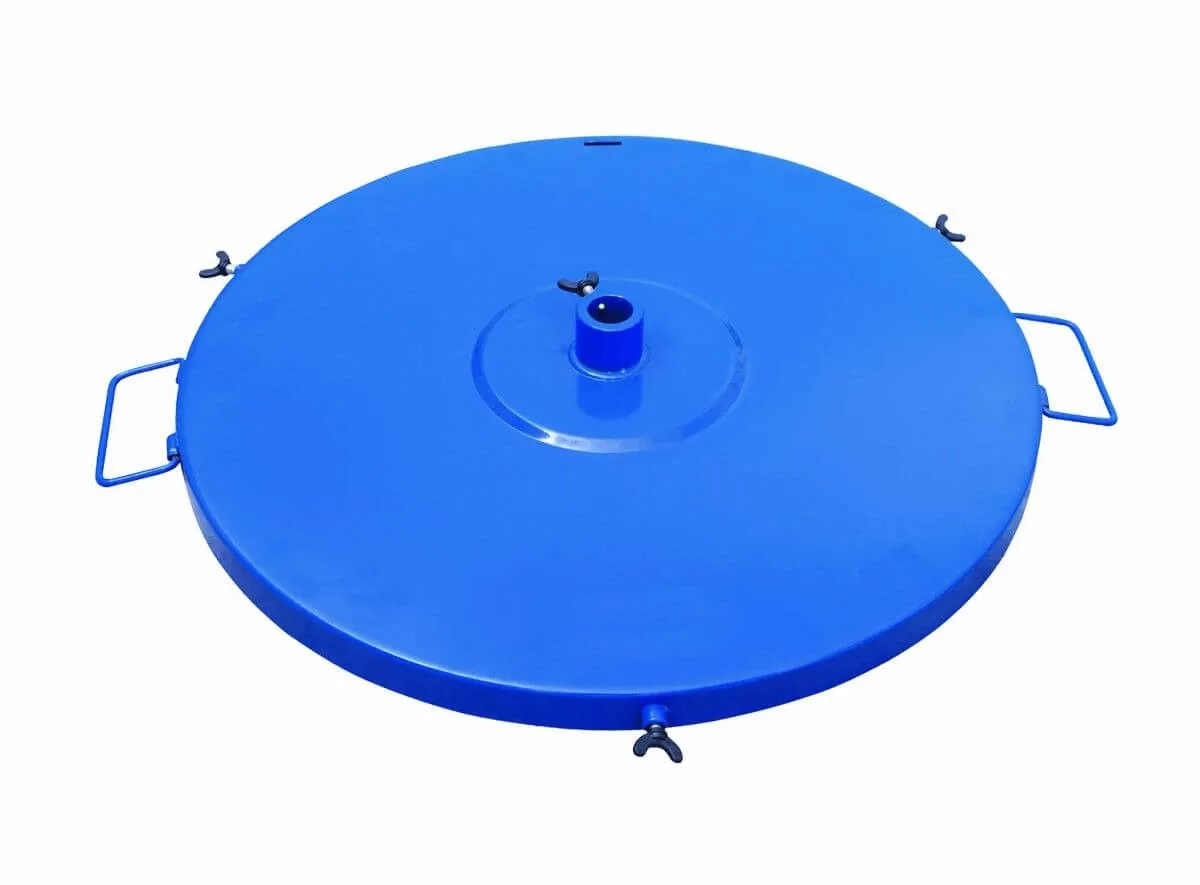

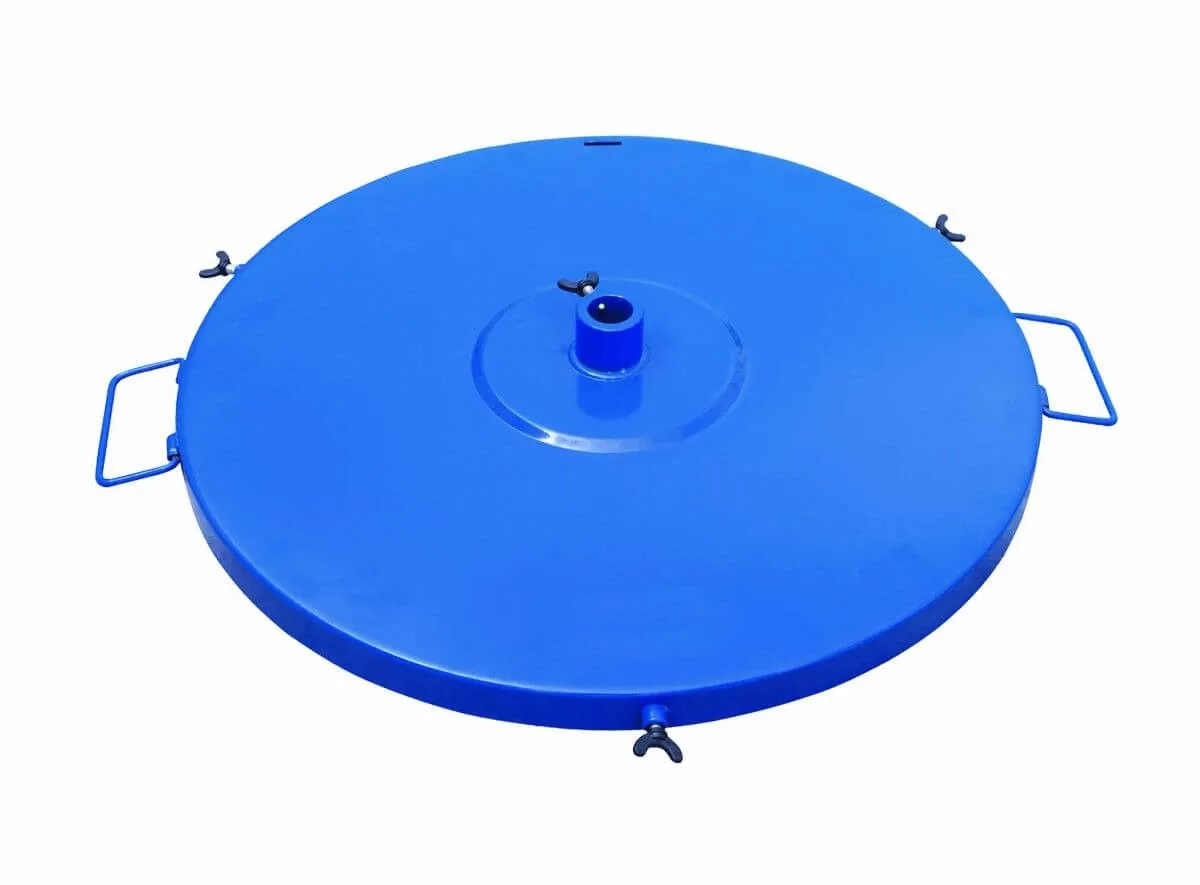

Drum Cover & Follower Plate for Grease Pump Systems

Industrial-grade drum cover with follower plate and wing-nut clamps. Maintains pump verticality while protecting grease from contamination.

Request QuoteDescription

Drum Cover & Follower Plate for Grease Pump Systems

Brief Overview

This drum cover and follower plate assembly is a critical component for any grease dispensing operation. It performs dual functions: sealing the drum against environmental contamination while maintaining the pump in the correct vertical position for consistent, reliable operation. The integrated follower plate is particularly valuable when working with heavy grease formulations, as it responds to pump suction to ensure continuous material feed without air gaps or dry runs. For shops running multiple pump configurations, consider pairing this with gasket-sealed alternatives to match varying drum conditions and material types.

Key Features

- Dust and Contamination Protection – Sealed design prevents dirt, moisture, and foreign particles from entering the grease drum

- Optimal Pump Positioning – Holds the pump assembly in true vertical alignment for maximum pressure consistency and flow rate stability

- Heavy-Grease Compatible – Follower plate responds to vacuum created by pump suction, preventing cavitation and material starvation

- Perimeter Wing-Nut Fastening – Four wing-nut clamps provide quick, tool-free installation and removal without disrupting drum positioning

- Integrated Lift Handles – Rectangular side handles on opposite edges simplify handling and drum repositioning during changeovers

- Smooth Painted Steel Construction – Durable gloss blue finish resists corrosion in workshop environments; clean surface minimizes grease carryover

- Central Access Port – Raised boss with central opening allows pump nozzle insertion while maintaining seal integrity

Business Advantages for Resellers

- High-Volume Replacement Item – Shops operating multiple grease dispensers need regular cover rotation; steady repeat sales potential

- Compatibility Across Equipment – Universal drum-top design fits standard 50-200 liter industrial grease drums, broadening your customer base

- Minimal Inventory Footprint – Lightweight, stackable design reduces warehouse space while maximizing margin per unit

- Upsell Opportunity – Customers often replace covers more frequently than follower plates; recommend rubber gasket versions for sealed environments or high-contamination risk shops

- Service-Level Differentiation – Positioning this as a maintenance essential (not a luxury) justifies margin and builds customer loyalty

Technical Specifications

| Specification | Detail |

|---|---|

| Primary Function | Drum sealing and follower plate assembly |

| Material | Painted steel construction (gloss blue finish) |

| Fastening Method | 4x wing-nut clamps (perimeter) + central wing-nut boss |

| Pump Orientation | Maintains vertical alignment for optimal operation |

| Follower Plate Action | Vacuum-responsive; designed for heavy grease formulations |

| Access Port | Central tubular opening (wing-nut secured) |

| Handling | Twin rectangular lift handles (opposite sides) |

| Compatibility | Standard industrial drum tops (50-200L capacity) |

| Finish | Corrosion-resistant gloss blue paint |

| Weight Class | Lightweight; easy single-technician installation |

Why Resellers Choose This Product

Pump downtime costs money. A contaminated grease supply or a pump running at an angle translates to pressure loss, nozzle clogging, and callbacks. This cover eliminates both problems while the follower plate ensures consistent feed on heavy materials—eliminating the air pockets that waste labor and frustrate technicians. The four wing-nut design means your customers can swap drums in seconds, not minutes. Stock this alongside your pump systems and you'll see immediate repeat orders.

Stock this as a core maintenance item. Pair it with your pump systems and recommend it at every installation. Your customers will return for replacements—count on it.