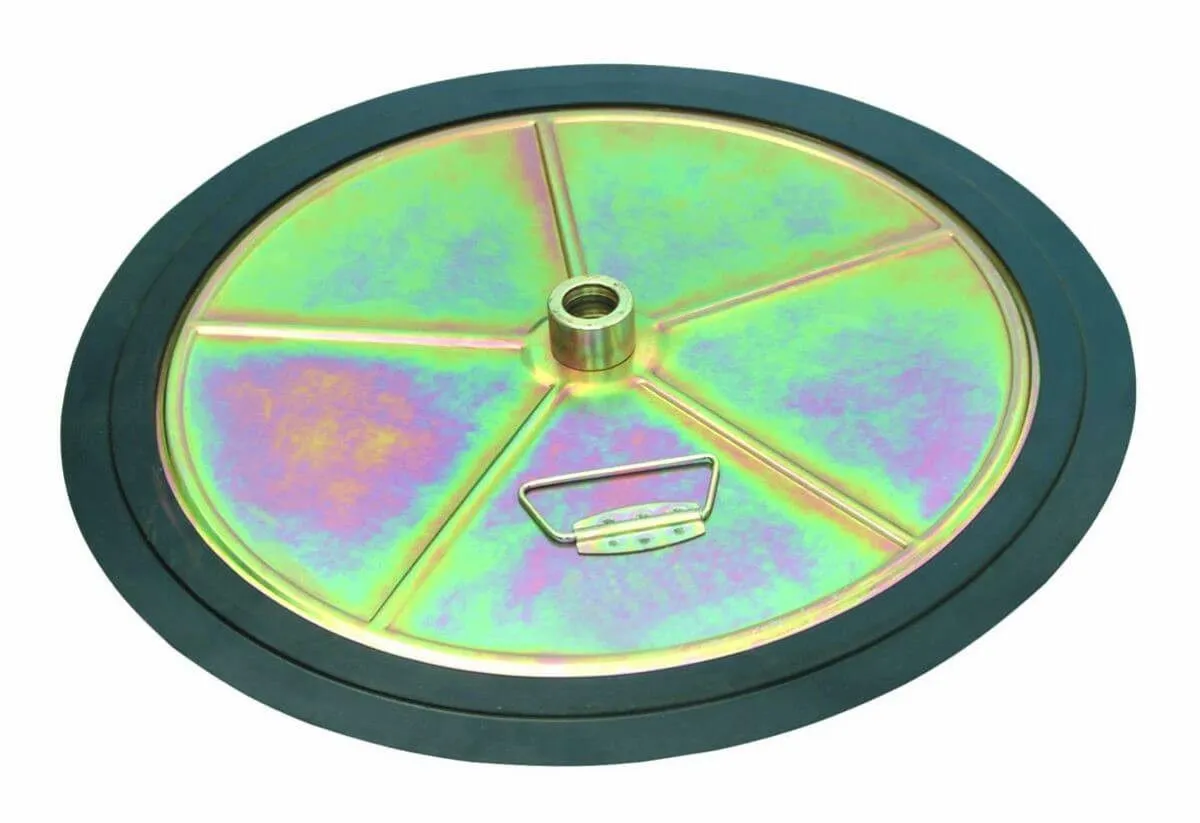

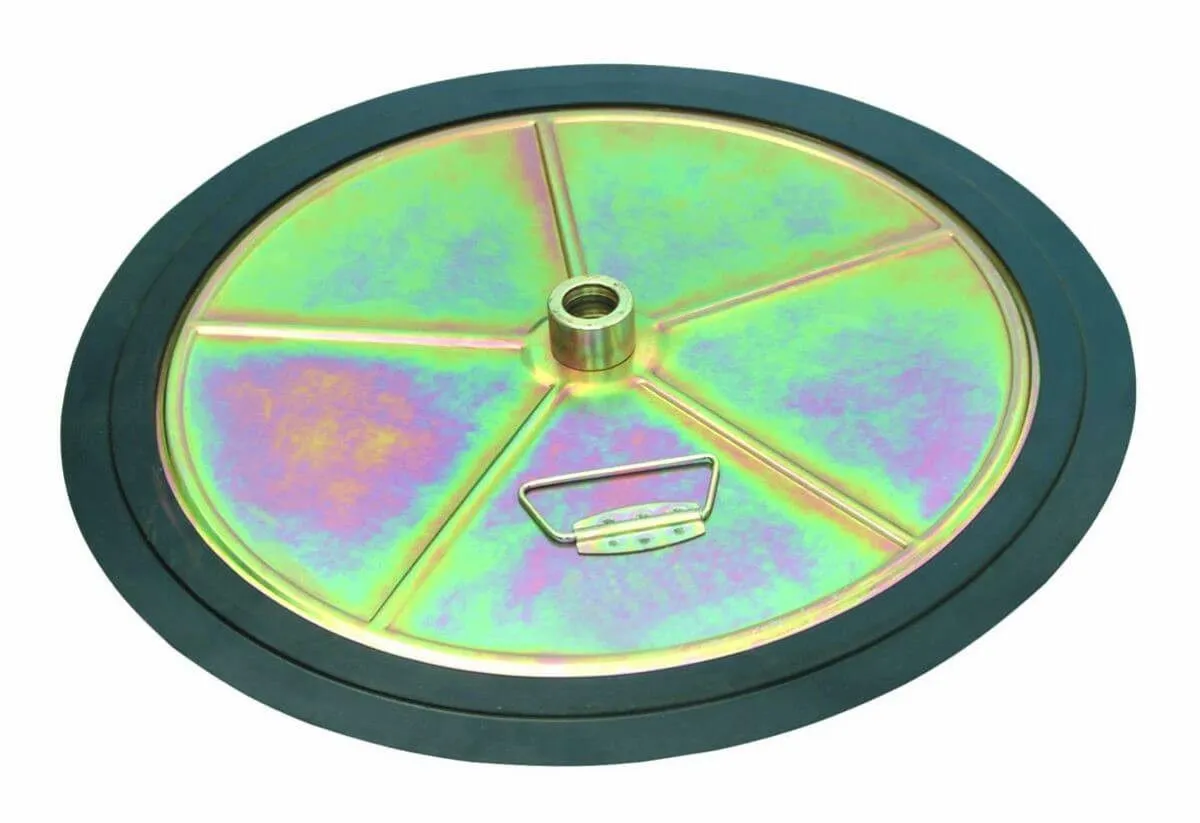

Drum Cover & Follower Plate with Rubber Gasket Seal

Sealed drum cover and follower plate for grease pump systems, prevents contamination and ensures optimal vertical operation.

Request QuoteDescription

Drum Cover & Follower Plate with Rubber Gasket Seal

Brief Overview

This dual-function drum cover and follower plate is an essential accessory for grease pump systems, designed to maintain product integrity and pump efficiency. The stamped metal construction with integrated rubber gasket creates an effective seal against the drum opening, while the follower plate mechanism—critical when dispensing heavy-viscosity greases—automatically adjusts to drum level as material is withdrawn. For operations requiring compatible sealing solutions for larger capacity drums or alternative plate configurations, multiple sizes and specifications are available.

Key Features

- Dual Functionality: Serves as both protective cover and vacuum-assisted follower plate in a single component

- Effective Sealing: Bonded rubber gasket ring around the outer rim prevents dust and moisture ingress

- Radial Stiffening Ribs: Stamped metal design with reinforcement ribs provides structural rigidity and prevents flexing under vacuum pressure

- Threaded Central Boss: Secure attachment point for mounting to drum opening or pump adapter

- Integrated Handle: Fold-down rectangular handle with rivet fastening allows easy removal and positioning

- Zinc/Chrome Finish: Corrosion-resistant plating protects metal substrate in warehouse and shop environments

Business Advantages for Resellers

- High-Margin Consumable Accessory: Low unit cost with predictable repeat orders as gaskets wear and plates require replacement

- Essential Upsell: Every grease pump system requires at least one cover plate—position as mandatory at point of pump sale

- Wide Application Base: Compatible with standard drum-mounted pump systems across multiple industries (automotive service, industrial maintenance, manufacturing)

- Inventory Efficiency: Compact flat-packed storage requires minimal warehouse footprint for high-turnover SKU

- Customer Retention Driver: Maintenance replacement creates recurring revenue from existing pump customers

Technical Specifications

| Specification | Detail |

|---|---|

| Construction Material | Stamped steel |

| Surface Finish | Zinc/chrome plating |

| Sealing Element | Bonded rubber gasket ring |

| Attachment Method | Threaded central boss |

| Handle Type | Fold-down rectangular with rivet mounting |

| Primary Function | Contamination prevention & follower plate action |

| Application | Grease pump drum systems |

Why This Matters to Your Customers

Mechanics and maintenance technicians operating grease pumps face two persistent problems: contamination of premium greases and inefficient dispensing of heavy-viscosity products. This cover plate addresses both simultaneously. The rubber gasket maintains a clean interior, preventing dust and shop debris from mixing with expensive lubricants. The follower plate function—activated by the pump's vacuum as grease is drawn out—eliminates the air gaps that would otherwise form at the drum bottom, ensuring consistent pressure and flow even as inventory depletes.

For shops using heavy-weight greases (NLGI 2 and above), the follower plate is not optional—it's mandatory for reliable pump operation. Without it, vacuum loss creates dispensing inconsistencies that frustrate technicians and waste time.

Call to Action

Stock this essential accessory in every pump sale. It's a low-cost add-on that prevents customer complaints and creates a natural reorder cycle. Ensure you maintain multiple sizes and specifications to cover your full pump range—check your inventory against all compatible alternative plate designs available in the catalog.