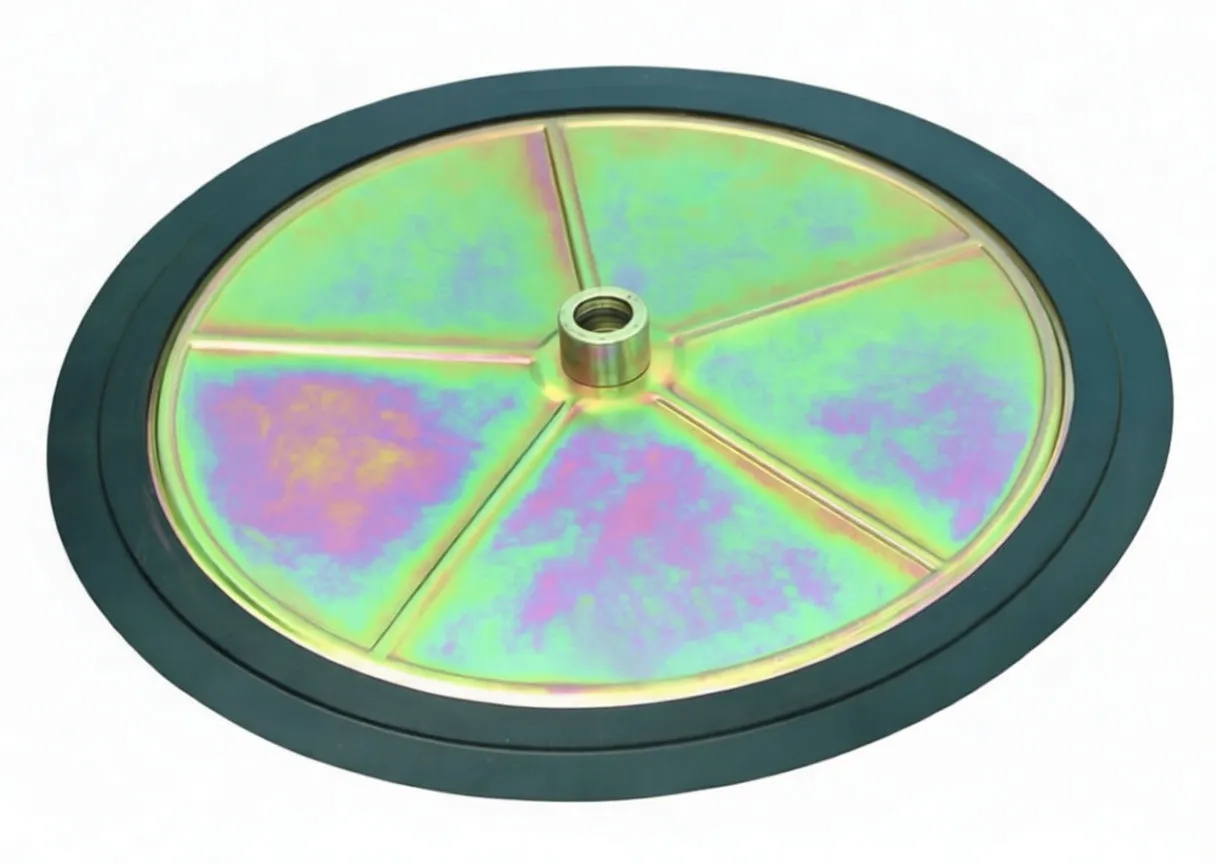

Drum Cover & Follower Plate with Rubber Gasket Seal

Stamped steel drum cover with integrated follower plate and rubber gasket—essential for grease drum protection and pump efficiency.

Request QuoteDescription

Drum Cover & Follower Plate with Rubber Gasket Seal

Brief Overview

This stamped steel drum cover and follower plate assembly is engineered to protect grease supplies from contamination while maintaining optimal pump performance. The integrated design combines dust exclusion with active material transfer, making it an indispensable component for any grease lubrication system. For shops requiring alternative mounting options, drum covers with wing-nut clamp systems offer flexible installation flexibility across different drum configurations.

Key Features

- Dust and Contamination Protection: Sealed cover design prevents environmental impurities from compromising grease quality and pump longevity

- Integrated Follower Plate: Actively follows grease level in the drum, eliminating air gaps that reduce pump efficiency

- Vacuum-Driven Operation: The pump's suction action pulls the follower plate toward the drum bottom, ensuring consistent material delivery and preventing cavitation

- Wide Rubber Gasket Seal: Precision-molded elastomer ring provides an airtight perimeter seal against the drum wall

- Radial Rib Reinforcement: Pressed steel ribs distribute load evenly and prevent flexing under vacuum conditions

- Central Threaded Boss: Standardized attachment point for pump rod or coupling mechanism

- Metal Handle/Retainer Tab: Integral fold-up access point for manual removal and maintenance

- Yellow-Green Iridescent Plating: Durable corrosion-resistant coating suitable for industrial environments

Why Distributors Specify This Component

Stock Velocity: Grease drum systems are consumable-adjacent—every setup requires a cover/follower plate. This creates steady, predictable reorder demand from your customer base.

Margin Sustainability: Low per-unit cost paired with universal application across drum lubrication equipment allows for healthy wholesale-to-retail spreads.

Customer Retention: Shops that run grease systems will return regularly for replacement gaskets and follower plates. Position this product as the foundational component in your lubrication supply ecosystem.

Technical Credibility: Specifying engineered drum covers (rather than improvised alternatives) builds your reputation with professional maintenance teams.

Technical Specifications

| Specification | Detail |

|---|---|

| Construction Material | Stamped steel with iridescent corrosion-resistant plating |

| Sealing Element | Molded rubber gasket ring (wide profile) |

| Attachment Method | Central threaded boss + fold-up metal handle with fasteners |

| Design Type | Vacuum-activated follower plate |

| Rib Pattern | 5-segment radial ribs for load distribution |

| Functional Purpose | Dust exclusion + active material following |

| Mounting Compatibility | Standard drum opening (gasket accommodates typical drum wall profiles) |

Application Context

This cover/follower plate assembly is the standard specification for:

- Centralized grease lubrication systems in manufacturing plants

- Heavy-duty mobile equipment requiring drum-mounted grease supplies

- Industrial maintenance operations where contamination control is non-negotiable

- High-viscosity grease transfer where follower plate action prevents air introduction

Closing Statement

Stock this product as the non-negotiable first step in any grease lubrication system. The combination of contamination protection and active material following ensures your customers achieve both equipment longevity and pump reliability—factors they'll credit directly to your supply quality.