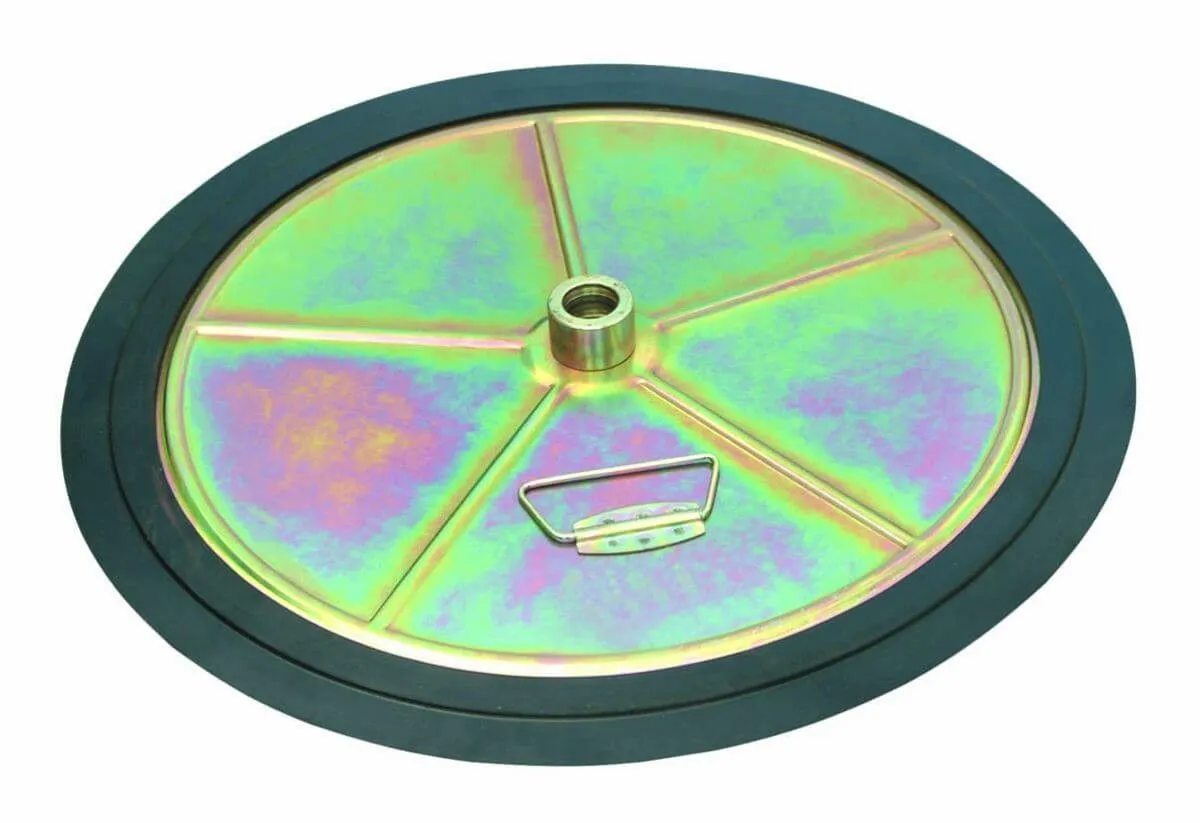

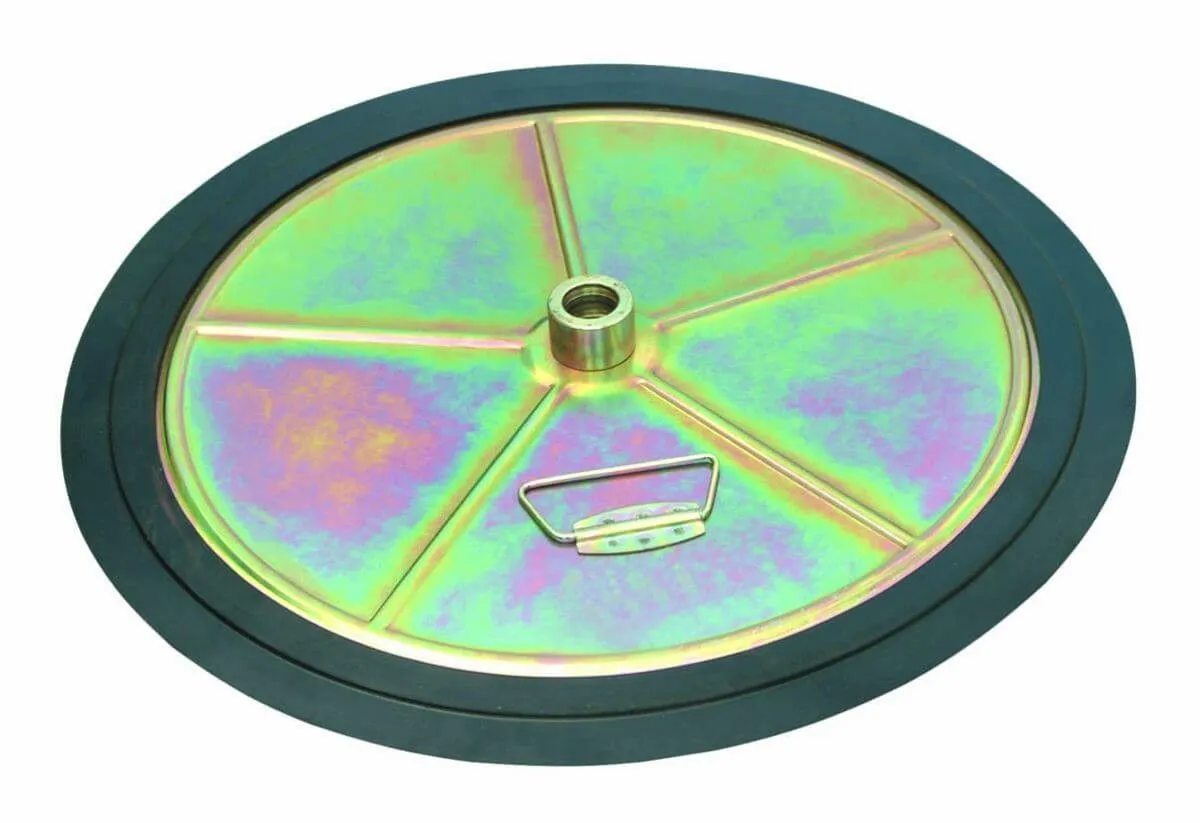

Drum Cover & Follower Plate with Rubber Gasket Seal, Zinc-Plated Steel

Zinc-plated steel drum cover with rubber gasket seal and follower plate for grease pump systems. Prevents contamination and maintains vertical pump operation.

Request QuoteDescription

Drum Cover & Follower Plate with Rubber Gasket Seal

Brief Overview

This drum cover and follower plate assembly is engineered for stationary grease dispensing systems, protecting pump integrity and extending operational lifespan. The zinc-plated steel construction with integrated rubber gasket seal prevents dust, moisture, and external contaminants from compromising grease quality during storage and use. The follower plate mechanism is essential when working with heavy or high-viscosity greases, as it maintains vacuum-driven contact with the drum bottom, ensuring consistent flow and eliminating air pockets. For shops requiring multiple mounting options, complementary solutions include alternative clamp-based designs and gasket-sealed variants for different drum configurations.

Key Features

- Zinc-plated steel construction – Corrosion-resistant finish for long service life in workshop and outdoor environments

- Reinforced radial ribs – Stamped ribbed design provides structural rigidity and prevents drum deflection under pressure

- Thick rubber gasket seal – Circumferential sealing rim ensures airtight closure, blocking dust and moisture ingress

- Integrated follower plate – Maintains contact with grease surface, eliminating air gaps and enabling vacuum-driven pump operation

- Threaded central port – Standard connection point for pump coupling

- Fold-flat handle – Hinged design for convenient drum access without interference during installation

Business Advantages for Resellers

- High-margin accessory: Consumable-adjacent product with recurring demand as seals wear and drums are serviced

- Compatibility: Works with standard 50L and 200L industrial grease drums, expanding your addressable market

- Low inventory footprint: Compact, stackable design allows bulk stock without excessive warehouse space

- Essential for heavy-grease operations: Shops using high-viscosity specialty greases cannot operate efficiently without a functional follower plate—creates strong selling proposition

- Preventive maintenance angle: Market as a contamination-prevention tool that protects expensive pump systems and extends fluid lifespan

Technical Specifications

| Specification | Detail |

|---|---|

| Material | Zinc-plated carbon steel |

| Gasket Material | Nitrile rubber (thick, compression-sealed) |

| Design Type | Stamped disc with radial reinforcement ribs |

| Central Port | Threaded boss (standard G1/4 or equivalent) |

| Handle Type | Fold-flat hinged bracket |

| Sealing Method | Compression gasket rim |

| Surface Finish | Iridescent zinc plating |

| Applicable Drum Sizes | 50L, 200L industrial drums |

| Function | Cover + follower plate (dual-function) |

Why This Design Matters

The follower plate mechanism directly addresses a critical challenge in grease dispensing: as the pump extracts material from the drum, atmospheric pressure can cause the drum walls to collapse inward or create air voids above the grease surface. This compromises pump performance and introduces contamination pathways. The vacuum created by the pump automatically pulls the follower plate downward, maintaining surface contact and preventing air infiltration. The rubber gasket simultaneously seals the drum from external dust and moisture—a dual-purpose design that eliminates the need for secondary sealing solutions.

The reinforced rib structure ensures the cover remains flat under repeated handling and the slight pressure differentials created by pumping cycles, preventing warping that would break the gasket seal.

Call to Value

Stock this cover-and-follower assembly as a core inventory item for any shop running centralized grease systems. Offer it as a maintenance recommendation during pump service calls, and bundle it with pump units to increase perceived value. At this price point, it's an easy upsell with strong margin potential.