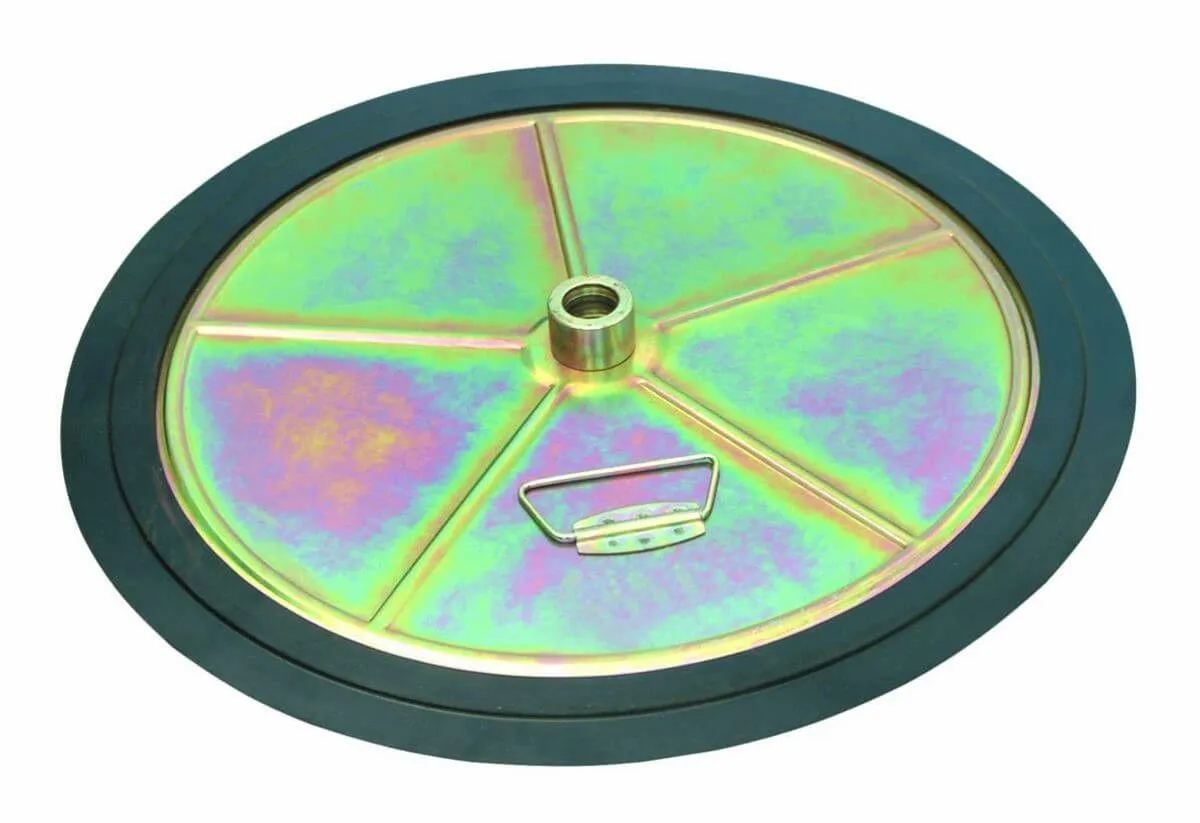

Drum Cover & Follower Plate with Rubber Gasket Seal, Zinc-Plated Steel

Sealed drum cover with follower plate for grease pump systems. Prevents contamination and maintains vertical pump operation.

Request QuoteDescription

Drum Cover & Follower Plate with Rubber Gasket Seal

Brief Overview

This zinc-plated steel drum cover and follower plate assembly is engineered to protect grease pump systems from contamination while maintaining optimal pump performance. The integrated rubber gasket seal creates an airtight barrier against dust and impurities, while the follower plate design ensures consistent material feed during heavy grease applications. For shops running multiple grease drum setups, consider pairing this with compatible clamp-based mounting systems to streamline installation across your equipment.

Key Features

- Rubber Gasket Seal: Durable elastomer lip creates a tight seal against the drum interior, blocking dust and environmental contaminants from entering the grease supply

- Follower Plate Design: Engineered to track material level and prevent air gaps in heavy-viscosity grease applications through vacuum-assisted descent

- Zinc-Plated Steel Construction: Corrosion-resistant finish suitable for shop environments with moisture and chemical exposure

- Radial Rib Reinforcement: Six stamped channels distribute load evenly and prevent flexing during pump operation

- Vertical Pump Positioning: Geometry maintains drum orientation for gravity-assisted pump function and consistent delivery pressure

- Fold-Down Bail Handle: Integrated lifting mechanism for safe, one-handed drum positioning and removal

Business Advantages for Resellers

- High-Margin Consumable Accessory: Wear items with predictable replacement cycles create recurring revenue from existing customers

- Essential Maintenance Upsell: Every grease pump drum requires a cover/follower system—ideal add-on to pump sales

- Inventory Efficiency: Single SKU serves multiple drum sizes and pump configurations, reducing SKU complexity

- Competitive Differentiation: Offering sealed covers positions your shop as quality-conscious, justifying premium grease supply pricing

Technical Specifications

| Specification | Detail |

|---|---|

| Material | Zinc-plated steel |

| Finish | Chromate conversion coating (iridescent zinc) |

| Sealing Element | Black rubber gasket lip |

| Central Boss | Threaded, raised design for secure fastening |

| Structural Design | Six radial ribs for reinforcement |

| Handle Type | Fold-down bail assembly |

| Primary Function | Dust exclusion + follower plate operation |

| Compatibility | Standard grease pump drum systems |

Why This Matters for Your Shop

Heavy grease applications demand aggressive vacuum pressure to extract material from drums. Without a proper follower plate, air voids form at the drum bottom, causing pump cavitation and delivery inconsistency. The gasket seal prevents water and airborne contaminants from degrading grease quality during storage—a critical factor for high-temperature bearing applications where oxidized grease fails prematurely. Resellers who bundle this cover with grease supply contracts build customer loyalty through reliable equipment performance.

Ready to stock this essential pump accessory? Volume pricing available for bulk orders. Contact your account manager for distributor rates.