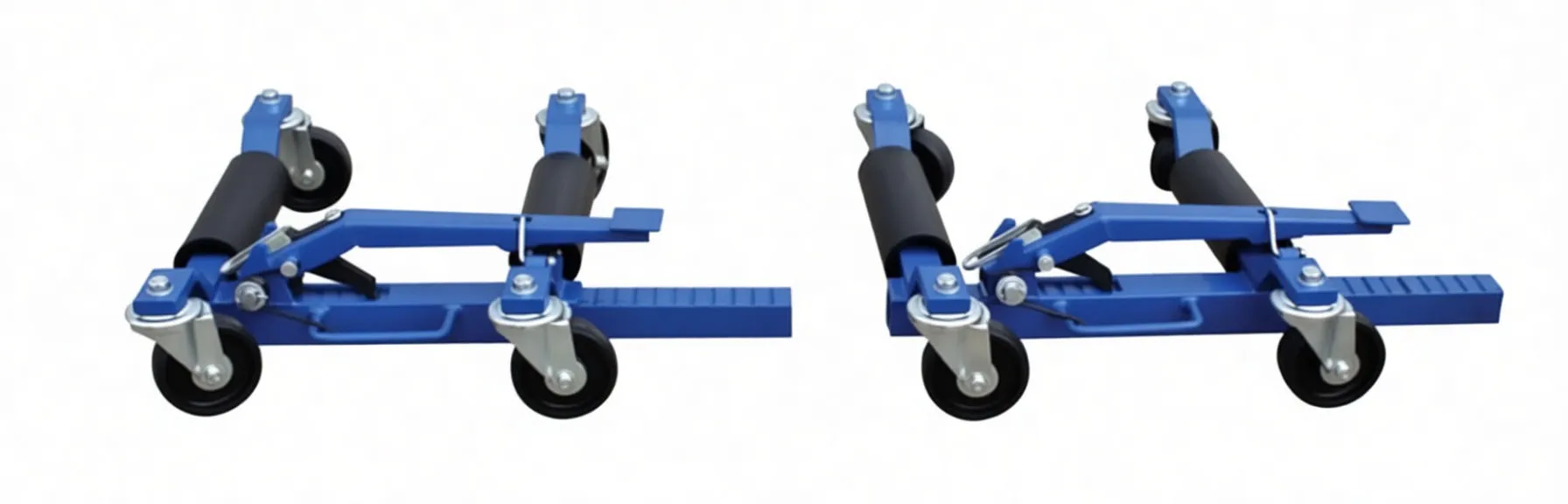

567kg Capacity Maneuvering Mover with Swivel Casters and Adjustable Load Beam

Heavy-duty maneuvering mover rated for 567kg loads with four swivel casters and adjustable positioning beam for flexible machinery relocation.

Request QuoteDescription

567kg Capacity Maneuvering Mover with Swivel Casters and Adjustable Load Beam

Brief Overview

This 567kg maneuvering mover delivers the precise load control and directional flexibility your shop needs for repositioning heavy machinery, industrial equipment, and large assemblies. The four swivel caster design eliminates the directional constraints of fixed-wheel systems, allowing operators to maneuver in any direction without repositioning the load or using additional equipment.

Key Features

- Four Swivel Casters: Independent swivel wheels enable multi-directional movement without load rotation or repositioning

- Adjustable Load Beam: Slotted rail with indexed positioning allows customization for varying equipment footprints and weight distribution

- Foam Roller Load Surface: Low-friction cylindrical foam pads protect equipment finish and distribute weight evenly across the load beam

- Ratchet Locking Lever: Secure load positioning with indexed locking mechanism to prevent unintended load shift during setup

- Heavy-Duty Steel Frame Construction: Powder-coated blue steel base with zinc-plated caster brackets for corrosion resistance

- Low-Profile Design: Compact height minimizes lifting requirements and fits under standard machinery plinths

- Dual-Unit Configuration: Sold as a matched pair for balanced load distribution across four contact points

Why Resellers Choose This Product

Efficient Machinery Relocation: The four-point swivel system reduces the labor intensity of heavy equipment repositioning—a premium service many shops underutilize. This tool enables faster turnaround on facility reconfigurations and maintenance access, creating new service revenue opportunities.

Broad Application Across Shop Types: Works equally well in automotive facilities (engine block repositioning), machine shops (lathe/mill movement), industrial maintenance, and general equipment handling. The 567kg capacity covers most mid-range machinery and assemblies.

Proven Durability in Professional Environments: Steel construction, indexed locking, and powder-coated finish ensure multi-year reliability in high-use settings. Minimal maintenance requirements translate to strong customer satisfaction and repeat purchases.

Competitive Margin on Essential Equipment: Heavy-duty maneuvering tools sit in a mid-price range with strong perceived value. Customers recognize the cost savings versus hiring outside equipment movers or purchasing machinery-specific dollies.

Technical Specifications

| Specification | Details |

|---|---|

| Load Capacity (Pair) | 567kg total |

| Caster Type | 4x swivel casters per pair (8 wheels total) |

| Caster Wheels | Black rubber or polyurethane compound |

| Load Surface | Cylindrical foam rollers (protect equipment finish) |

| Positioning System | Indexed adjustable rail with ratchet locking lever |

| Frame Material | Heavy-duty steel with powder-coated blue finish |

| Caster Brackets | Zinc-plated steel for corrosion resistance |

| Configuration | Sold as matched pair |

| Profile Height | Low-profile design (specific height per adjustable positioning) |

| Locking Mechanism | Ratchet lever with indexed positions |

Professional Application Notes

This mover pair is engineered for controlled, non-rolling repositioning of machinery on shop floors. The adjustable beam accommodates equipment with different base dimensions, while the swivel casters eliminate the need for floor space clearance on two axes. Ideal for rotating machinery for access, moving equipment between workstations, and temporary staging during maintenance or reconfiguration.

Ready to add precision machinery movement to your inventory? Order in bulk to capture facility upgrades, maintenance contracts, and equipment relocation projects. Distributors report strong demand during shop expansions and equipment upgrades.