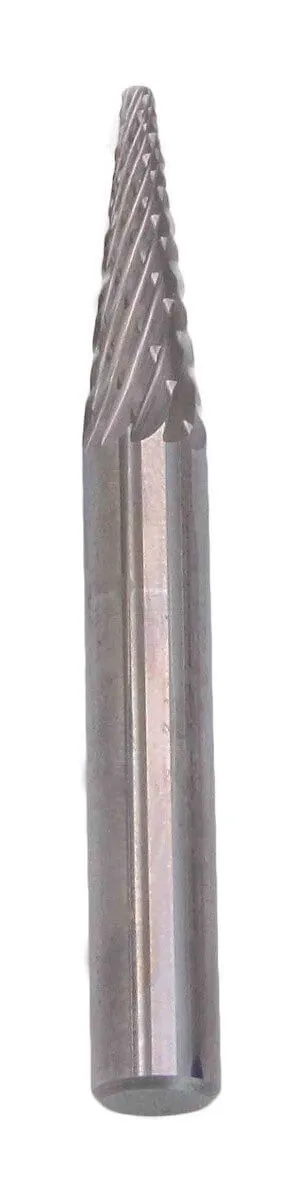

Milling Drill 6×50mm SKM S6 – Precision Conical Burr for Metal Finishing

Compact 6mm conical milling burr designed for deburring, finishing, and precision machining of gears and detailed metalwork.

Request QuoteDescription

Milling Drill 6×50 SKM S6 – Precision Conical Burr for Metal Finishing

Brief Overview

This 6×50mm SKM-type milling drill is a precision rotary cutting tool engineered for deburring, edge finishing, and detailed metal shaping operations. The tapered conical head with multi-flute helical geometry produces smooth, burr-free surfaces on complex workpieces—particularly effective for gear teeth, small recesses, and intricate component edges. Built for high-speed rotary applications in production environments, this tool pairs excellent surface finish quality with compact proportions ideal for detailed work. Pair this with larger conical burrs in the 10×65mm range for a complete finishing toolkit, or explore alternative carbide geometries for specialized applications.

Key Features

- Conical Tapered Head – Multi-flute helical cutting edges optimized for smooth finishing and deburring

- Compact 6mm Shank – Fits standard 6mm rotary tool chucks and flexible shaft holders

- 50mm Overall Length – Balanced design for precision hand-held and machine-mounted work

- Smooth Surface Finish – Engineered geometry eliminates chatter and produces refined, burr-free results

- Precision Machining – Ideal for gear production, component deburring, and detail work in tool manufacturing

Business Advantages for Distributors

- High Turnover Product – Essential consumable for tool manufacturers, metalworking shops, and precision machining facilities

- Compact Portfolio Footprint – Minimal storage space required for strong margin contribution

- Broad Industrial Appeal – Used in automotive, gear manufacturing, tool production, and small-parts finishing

- Reseller Value – Low per-unit cost with high markup potential; easy to bundle with rotary tool accessories

- Production Efficiency – Customers invest in repeat orders due to tool wear in high-volume finishing operations

Technical Specifications

| Dimension | Value |

|---|---|

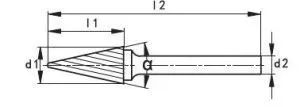

| Head Diameter (d1) | 6 mm |

| Shank Diameter (d2) | 6 mm |

| Head Length | 18 mm |

| Overall Length (L2) | 50 mm |

| Type | SKM – Conical Tapered Burr |

| Cutting Geometry | Multi-Flute Helical |

| Application | Deburring, Finishing, Metal Shaping |

Why Stock This Tool

The 6×50mm SKM milling drill fills a critical niche in finishing operations where surface quality and precision matter. Its small profile makes it invaluable for detailed work—gear tooth finishing, hole deburring, and fine edge work—while the smooth helical flute design minimizes vibration and produces superior finishes compared to single-flute alternatives. For shops running high-speed rotary equipment, this is a wear item with predictable reorder cycles, making it reliable revenue.

Recommended for: Tool manufacturing, precision metalworking, automotive component finishing, gear production, and any operation requiring smooth deburring of detailed workpieces.

Stock this SKM-type burr as part of your rotary finishing toolkit. Excellent margin opportunity with consistent reseller demand.