Milling Drill ZYA-S Type D1×L1: 8×65mm, D2×L2: 6×20mm

Tungsten-carbide cross-cut milling drill for precision deburring and face machining. Smooth surface finish on metals, plastics, and composites.

Request QuoteDescription

Milling Drill ZYA-S Type D1×L1: 8×65mm, D2×L2: 6×20mm

Brief Overview

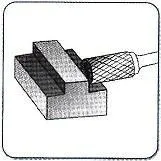

This tungsten-carbide cross-cut milling drill is engineered for precision deburring, edge breaking, and face machining operations in tool production and component finishing. The diagonal cross-flute cutting geometry delivers superior surface finish on a wide range of materials including aluminum, steel, plastics, and composites. Whether you're running a tool-making operation or providing finishing services to manufacturing clients, this burr excels at producing smooth, burr-free workpiece surfaces. Consider pairing it with other precision carbide milling drills to build a complete deburring toolkit for your shop.

Key Features

- Cross-Cut Carbide Head – Diagonal flute pattern creates a starburst cutting geometry for multi-directional chip evacuation and superior surface finish

- Dual-Diameter Design – 8mm primary cutting head (65mm length) with 6mm shank (20mm length) for accessibility in tight machining zones

- End and Side Machining – Multi-radial cutting edges enable both face (end) and perimeter edge work in a single tool

- Tungsten-Carbide Construction – Hard-wearing material resists wear and maintains edge sharpness across extended production runs

- Smooth Metallic Finish – Professional gray coating protects the tool during storage and handling

Business Advantages for Resellers

This milling drill addresses a critical need in tool production and component finishing:

- High Repeat Demand – Deburring is a mandatory finishing step; shops cannot skip this process

- Wide Material Compatibility – Carbide construction handles ferrous metals, non-ferrous, and composites, reducing SKU complexity

- Professional Finish Quality – Delivers the smooth surface finish that distinguishes quality work, building customer loyalty and repeat orders

- Tool Production Essential – Indispensable for any tool-making operation; essential inventory item for machine shops and tool manufacturers

- Bulk Order Margins – Carbide tools command healthy margins; stock in quantity to meet consistent shop demand

Technical Specifications

| Parameter | Value |

|---|---|

| Primary Cutting Diameter (D1) | 8 mm |

| Primary Cutting Length (L1) | 65 mm |

| Shank Diameter (D2) | 6 mm |

| Shank Length (L2) | 20 mm |

| Material | Tungsten Carbide |

| Cutting Geometry | Cross-Cut (Diagonal Flute) |

| Application | Deburring, Face Milling, Edge Breaking |

| Workpiece Compatibility | Metal, Plastic, Composite |

Call to Value

Stock this precision carbide milling drill in your catalog to serve tool makers and finishing departments. The 8×65mm sizing strikes a balance between accessibility and cutting capacity, making it suitable for mid-range production runs and one-off precision work. Order in bulk to secure competitive margins and position your shop as a reliable source for professional-grade finishing tools.