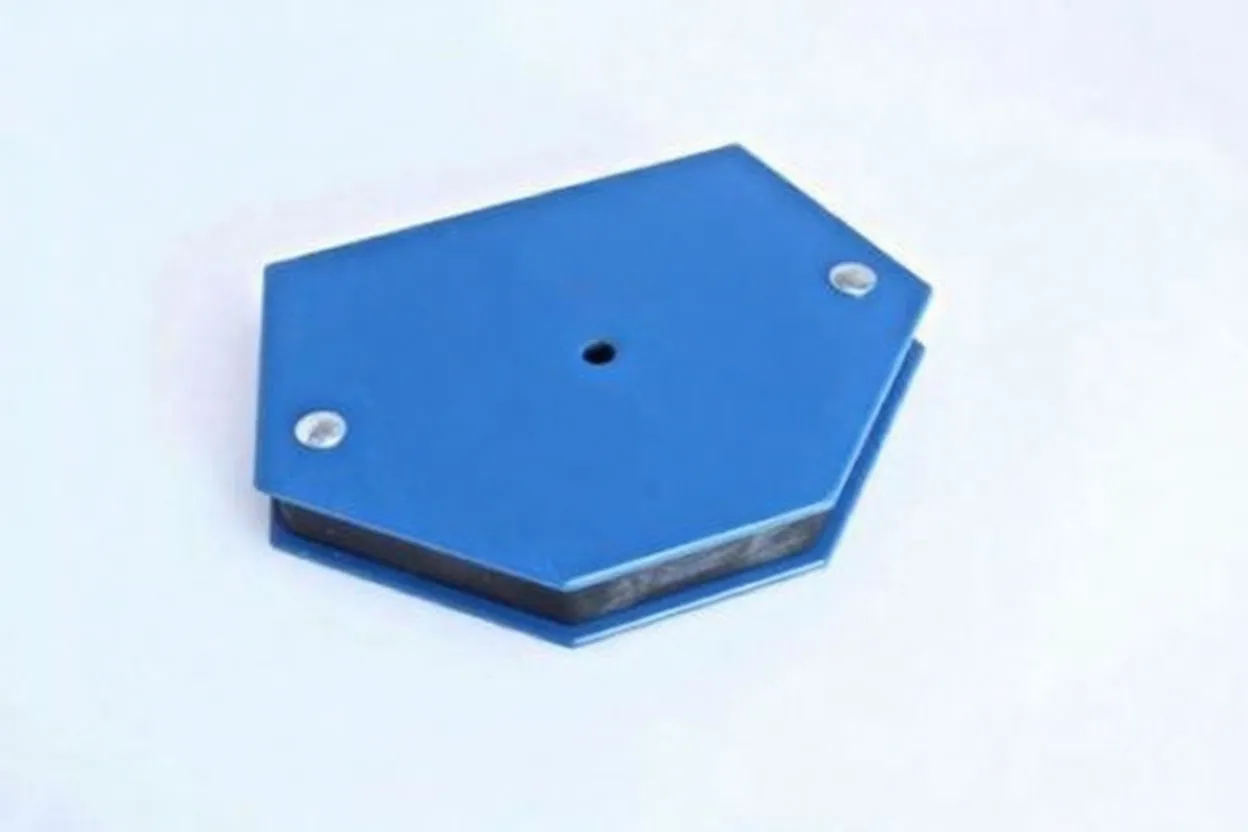

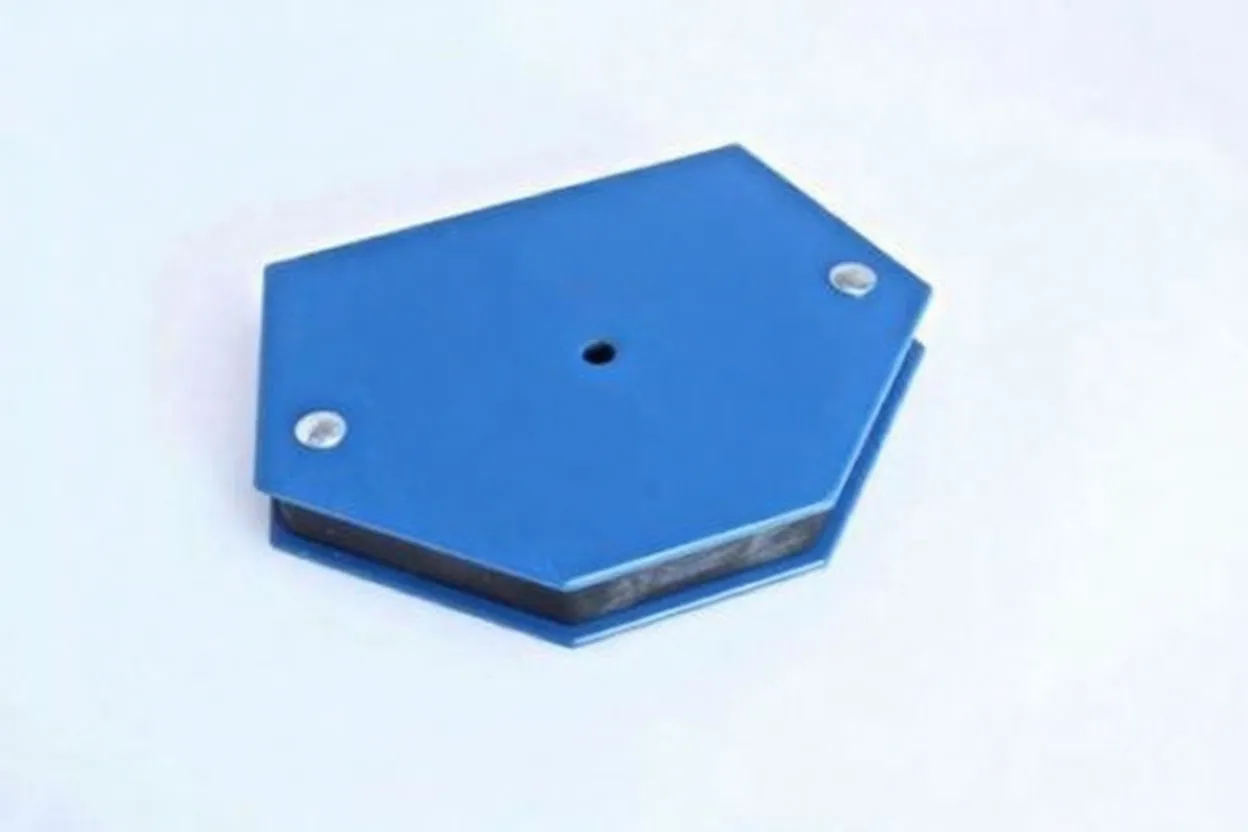

Multi-Angle Magnetic Welding Holder, 50lb (22kg) Holding Force, 6-Position

Professional-grade magnetic welding holder with six angle positions (30°–135°), 50lb holding force, and durable riveted steel construction.

Request QuoteDescription

Multi-Angle Magnetic Welding Holder, 50lb (22kg) Holding Force, 6-Position

Brief Overview

This 50lb magnetic welding holder delivers reliable workpiece positioning across six common angles—30°, 45°, 60°, 70°, 90°, and 135°—making it an essential reference tool for welding, soldering, fabrication, and precision assembly operations. The blue anodized steel construction and dual-magnet design ensure consistent holding force across extended work sessions. For smaller-scale operations or portable setups, compact multi-angle magnetic holders offer similar functionality in a portable four-piece kit format.

Key Features

- Six Angle Positions: Marked 30°, 45°, 60°, 70°, 90°, and 135° with white printed pictograms for quick visual reference

- 50lb (22kg) Holding Force: Dual-magnet construction maintains secure workpiece grip during welding and soldering

- Durable Riveted Steel Assembly: Inner and outer plates with riveted fasteners prevent delamination and extend service life

- 30mm Diameter Grip Ring: Central hole with inner ring sizing allows comfortable handling and one-handed repositioning

- Professional Blue Anodized Finish: Corrosion-resistant coating withstands workshop environments and repeated thermal cycles

- Compact Footprint: 102 × 155 × 17mm dimensions fit tight benchtop spaces and fixture layouts

Why Resellers Choose This Holder

High Turnover in Welding & Fabrication Shops:

Multi-angle holders are consumable reference tools that workshops buy in volume. Once integrated into a shop's workflow, repeat orders are frequent as units wear or are relocated to satellite benches.

Versatile Market Reach:

Single unit sells to welders, solderers, precision assemblers, and general fabrication work. No specialization required—any shop doing tack welding or temporary assembly positioning needs angle guidance.

Proven Durability Reduces Returns:

Riveted construction and dual-magnet design eliminate the weak points that plague cheaper alternatives. Lower return rates = healthier margins and customer satisfaction.

Bulk Order Economics:

The compact size allows substantial stock rotation with minimal shelf footprint. Ideal as an add-on item to larger tool orders, increasing average transaction value.

Technical Specifications

| Specification | Value |

|---|---|

| Holding Force | 50lb (22kg) |

| Angle Positions | 6: 30°, 45°, 60°, 70°, 90°, 135° |

| Material | Hardened Steel with Anodized Finish |

| Construction | Riveted Dual-Plate Assembly |

| Central Grip Ring Diameter | 30mm |

| Overall Dimensions | 102 × 155 × 17mm |

| Weight | Approximately 0.6kg |

| Primary Applications | Welding, Soldering, Fabrication, Assembly |

| Magnetic Layer Type | Industrial-Grade Dual Magnet |

Application Notes

Workshop Integration:

Position on welding benches, soldering stations, or fabrication fixtures as a permanent angle reference. The 30mm grip ring allows quick repositioning between jobs without removing from the work area.

Thermal Resilience:

Magnetic strength remains stable across typical workshop temperature ranges (−10°C to +50°C). Not suitable for direct contact with workpieces exceeding 100°C.

Portability:

At 102 × 155mm, this fits tool carts, mobile welding stations, and job-site setups. The riveted construction eliminates rattle and loosening during transport.

Stock and Resale Strategy

Stock this multi-angle holder as a gateway product to establish customer loyalty in fabrication shops. Bundle with precision magnetic bit holders for tool kits targeting assembly and electronics repair segments. The dual-market appeal (welding + soldering) ensures year-round demand.

The 50lb capacity positions it as a mid-tier offering—stronger than mini portable sets, more affordable than specialized hydraulic clamps. This creates natural tiering for customers upgrading from basic tools or stocking multiple benches.

Recommendation: Stock 10–15 units per distribution center to support monthly shop orders and impulse purchases. The compact size maximizes shelf efficiency while the proven durability minimizes warranty costs. This is a high-velocity, low-complexity product that strengthens your positioning in the welding and fabrication segment.