Pneumatic Articulated Support Arm with Joystick Control and Adjustable Clamp

Heavy-duty pneumatic support arm with dual-axis positioning, joystick control, and versatile clamping options for professional workshops.

Request QuoteDescription

Pneumatic Articulated Support Arm with Joystick Control and Adjustable Clamp

Brief Overview

The HELP ARM is a professional-grade pneumatic positioning and holding arm designed for workshops requiring flexible work support solutions. This articulated system combines pneumatic power with manual precision control, enabling technicians to position, support, and clamp components with minimal physical effort. The dual-pivot design delivers smooth, controlled movement across multiple work angles, making it an essential complement to other heavy-duty workshop support equipment in any service environment.

Key Features

- Pneumatic Power Supply: 8–10 bar operating pressure delivers consistent force without manual strain

- Joystick Control System: Integrated pneumatic switch with directional lever for intuitive up/down arm positioning

- Dual Articulated Arms: Two independent pivoting joints with bolt-secured hinge assemblies allow 360° positioning capability

- Adjustable Screw Clamp: Fine-threaded rod with star-knob adjustment and serrated plastic jaw provides secure, non-marring grip

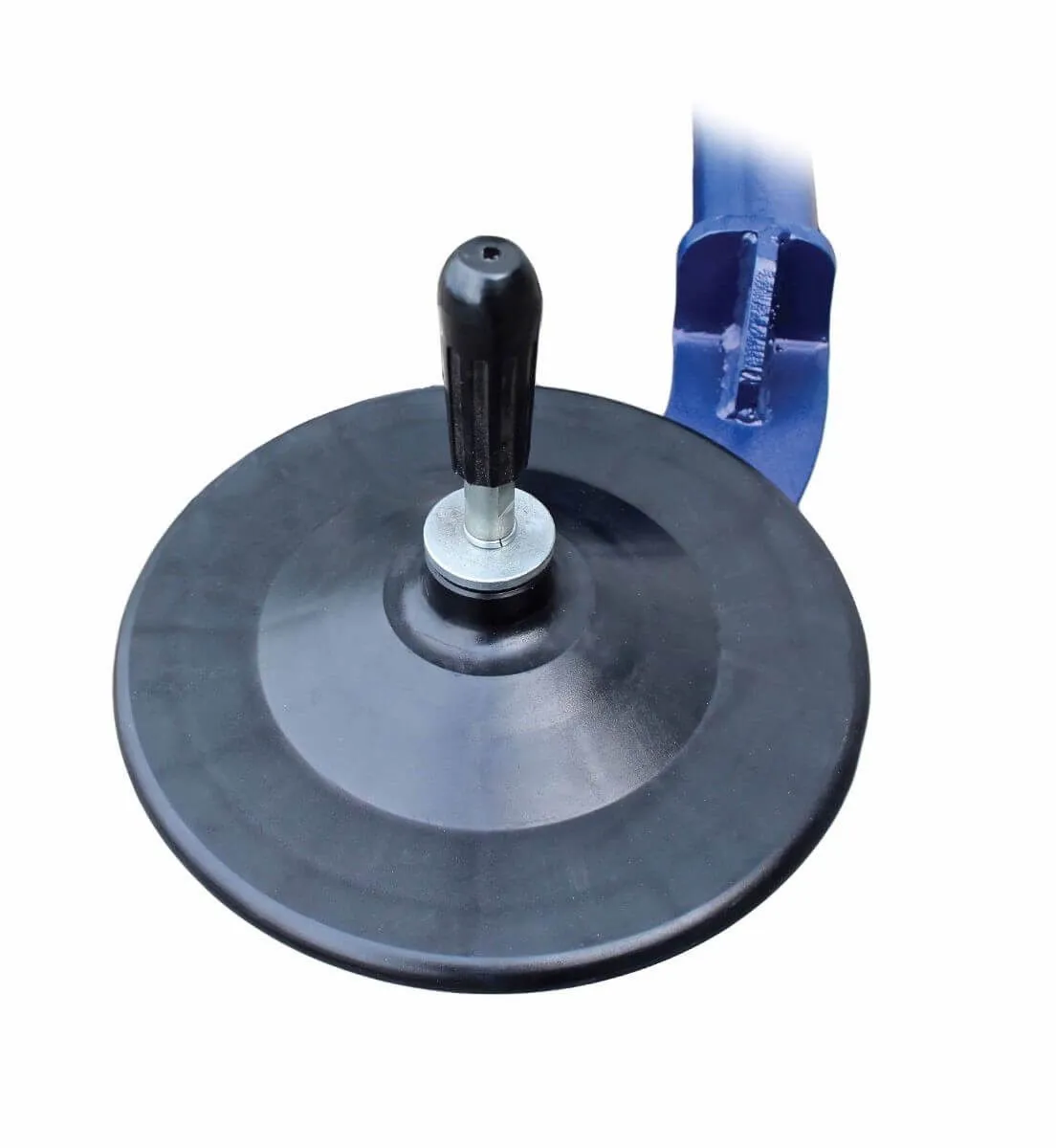

- Suction/Support Pad: Rubber-backed pad with adjustment handle for stable positioning on flat surfaces and tire work

- Heavy-Duty Construction: Powder-coated blue steel frame with welded joints rated for 6600 N cylinder pressure

- Professional Accessories Included: Pressure roller, pressure washer cone, edging disc, and holder for auxiliary accessories

- Low Noise Operation: <75 dB acoustic signature suitable for controlled shop environments

- Wide Temperature Range: Operational performance maintained from −5 °C to +40 °C

- Low-Profile Tire Compatibility: Specifically engineered for low-profile and run-flat tire applications

Business Advantages for Resellers

Shop Integration & Workflow: This pneumatic arm eliminates the need for multiple manual holding devices and reduces technician fatigue during extended positioning tasks. The single pneumatic supply connection simplifies installation in existing workshop compressed-air networks, and the compact footprint fits standard work bays without major retrofit.

Margin & Turnover Opportunity: Pneumatic positioning arms command consistent demand in tire service, automotive assembly, and general workshop environments. The accessory ecosystem (rollers, cones, edging discs) creates natural upsell opportunities and consumable replacement revenue. Bundle offerings with complementary support tools maximize basket size per transaction.

Durability & Reduced Support Costs: Welded steel construction and sealed pneumatic components ensure multi-year operational life with minimal maintenance. Standardized replacement parts (clamp pads, seals, cylinders) are readily available, reducing warranty claims and supporting long-term customer retention.

Technical Specifications

| Specification | Value |

|---|---|

| Power Source | Pneumatic (compressed air) |

| Operating Pressure Range | 8–10 bar |

| Cylinder Pressure Rating | 6600 N |

| Noise Level | <75 dB |

| Control Method | Joystick-actuated pneumatic switch |

| Positioning Axes | Dual articulated pivots (multi-angle support) |

| Clamp Type | Screw-threaded adjustment with serrated plastic jaw |

| Support Pad | Rubber-backed suction pad with manual handle |

| Frame Material | Powder-coated blue steel |

| Joint Construction | Welded with bolt-secured hinge assemblies |

| Mounting | Wall/base bracket with threaded leveling foot |

| Included Accessories | Pressure roller, pressure washer cone, edging disc, accessory holder |

| Operating Temperature Range | −5 °C to +40 °C |

| Application Focus | Low-profile tires, run-flat tires, general positioning work |

Value Proposition for Your Customers

Technicians benefit from reduced setup time and physical strain during repetitive positioning tasks. The pneumatic system responds instantly to control input, eliminating manual adjustment delays. The modular accessory system adapts to tire service, component assembly, and precision work—maximizing the tool's utility across multiple shop departments and justifying the investment through high utilization rates.

Ready to stock a professional-grade pneumatic positioning solution? The HELP ARM transforms workshop efficiency and creates steady replacement-parts revenue through its accessory ecosystem. Contact us for bulk pricing and technical support documentation.