Rotary Burr 12mm Head, 70mm Length, SPG Profile, S6 Shank

Precision rotary burr with cross-cut flutes for smooth finishing and detailed machining work across construction forms.

Request QuoteDescription

Rotary Burr 12mm Head, 70mm Length, SPG Profile, S6 Shank

Brief Overview

This rotary burr delivers precision finishing and detailed machining across diverse construction applications. The tapered oval cutting head features closely spaced diagonal cross-cut flutes in a spiral pattern, engineered to produce smooth, consistent surface finishes on workpieces. The 12mm head diameter with 6mm shank accommodates standard rotary tool chucks, making it compatible with existing shop equipment. For shops requiring multiple burr profiles, consider complementary options like smaller precision burrs or mid-range finishing tools to build a complete burr library.

Key Features

- Cross-Cut Flute Design: Closely spaced diagonal flutes create a crisscross spiral pattern that minimizes chatter and produces fine surface finishes

- Tapered Oval Profile: SPG geometry optimized for contour work, detail machining, and smooth finishing across irregular surfaces

- Smooth Polished Shank: 6mm diameter shank reduces tool runout and ensures stable chuck grip

- Extended Reach: 70mm overall length provides access to recessed or complex geometric areas

- High-Speed Steel or Carbide Construction: Durable metallic composition withstands repetitive cutting cycles and maintains edge geometry

Technical Specifications

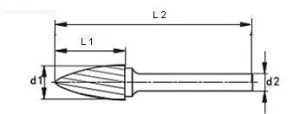

| Specification | Value |

|---|---|

| Head Diameter (d1) | 12 mm |

| Head Length (L1) | 25 mm |

| Shank Diameter (d2) | 6 mm |

| Overall Length (L2) | 70 mm |

| Flute Pattern | Cross-cut spiral |

| Head Profile | SPG (tapered oval) |

| Chuck Compatibility | Standard 6mm collet systems |

Business Advantages for Resellers

- High-Frequency Consumable: Burrs wear with use, creating consistent reorder demand from tool rental facilities, machine shops, and fabrication centers

- Margin-Friendly: Low unit cost with strong markup potential on bulk orders

- Stock Rotation: Complements larger burr profiles in your inventory; customers often purchase multiple sizes for different finishing tasks

- Professional Positioning: Offering a curated burr selection establishes your shop as a serious finishing tool supplier to precision machining operations

Ideal Applications

- Tool and die production

- Precision finishing and smoothing operations

- Detail work on cast or forged components

- Surface blending and edge finishing

- Contour machining on complex geometries

Stock this burr in volume to serve machine shops, tool rooms, and production facilities that rely on rotary finishing tools for surface quality and component precision.