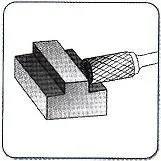

4mm Cylindrical Rotary Burr, Cross-Cut Flute Pattern, 50mm Length

Precision carbide rotary burr for deburring, finishing, and material removal on tool production and machining operations.

Request QuoteDescription

Product Description

Brief Overview

This 4mm cylindrical rotary burr is engineered for precision deburring, edge finishing, and material removal across a wide range of tool production and machining applications. The cross-cut diamond flute pattern delivers a smooth, controlled cutting action that minimizes chatter and produces excellent surface finishes on both ferrous and non-ferrous workpieces. The compact 4mm head diameter makes it ideal for detail work, intricate edges, and confined spaces where larger tools cannot operate. For shops requiring a broader range of cutting profiles, 6mm cross-cut rotary burrs and 4mm alternative flute patterns are available to complement your inventory.

Key Features

- Cylindrical Head with Rounded Tip: Star-like cutting profile enables work on edges, corners, and flat surfaces without sharp edges catching or gouging

- Cross-Cut Diamond Flute Pattern: Dense flute geometry produces fine chips and ensures smooth material removal with minimal vibration

- 4mm Shank Diameter (d1): Fits standard 1/8-inch rotary tool collets and pneumatic burr chucks

- 50mm Overall Length (L2): Compact length suitable for precision detail work and confined access areas

- Hardened Carbide Construction: Maintains edge integrity through extended use; resists thermal stress and maintains dimensional stability

- Silver/Gray Metallic Finish: Corrosion-resistant surface suitable for coolant-based operations

Specification Table

| Parameter | Value |

|---|---|

| Shank Diameter (d1) | 4 mm |

| Shank Length | 16 mm |

| Head Diameter (d2) | 6 mm |

| Overall Length (L2) | 50 mm |

| Flute Pattern | Cross-Cut Diamond |

| Head Profile | Cylindrical with Rounded Tip |

| Material | Hardened Carbide Steel |

| Finish | Silver/Gray Metallic |

Why Resellers Choose This Burr

Volume Demand: The 4mm size is the workhorse of precision finishing. Shops regularly replenish this size because it handles 60–70% of detail deburring tasks.

Margin Opportunity: Carbide burrs command strong margins due to material cost and precision manufacturing. Bulk stock of this popular size moves quickly and supports consistent turnover.

Cross-Sell Potential: Customers buying 4mm burrs typically purchase complementary 6mm and 8mm sizes for full-capability kits. Stock this alongside larger profiles to capture complete orders.

Industrial Durability: Hardened carbide construction means longer tool life between replacements—customers view this as an investment, not a consumable—supporting your reputation for quality.

Technical Application Notes

- Ideal For: Deburring cast edges, finishing precision tool components, smoothing internal corners, chamfering sharp edges, polishing workpiece surfaces

- Material Compatibility: Ferrous metals, aluminum, brass, plastics, composites

- Operating Speed: Suitable for pneumatic rotary tools operating 5,000–25,000 rpm (consult tool manufacturer for optimal speed)

- Surface Quality: Produces smooth, polished finishes without secondary sanding in most applications

Why This Size Matters for Your Inventory

The 4mm head diameter fills a critical gap between hand files and larger rotary burrs. It's precise enough for intricate tooling work yet robust enough for production deburring. Shops that stock only 6mm and larger sizes lose sales on detail-work jobs. This burr ensures you capture the full spectrum of finishing orders.

Stock Recommendation: Maintain quantity of 4mm cross-cut burrs proportional to 6mm inventory (roughly 1.5:1 ratio based on market demand). This size justifies dedicated shelf space and accelerates turnover in active shops.