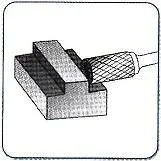

Rotary Burr 6mm x 50mm ZYA-S Profile, S6 Shank

Precision carbide rotary burr for deburring, grinding, and shaping. Multi-fluted cross-cut design delivers smooth surface finishes on metal and industrial materials.

Request QuoteDescription

Rotary Burr 6mm x 50mm ZYA-S Profile, S6 Shank

Overview

This 6mm rotary burr with ZYA-S profile is engineered for precision deburring, grinding, and surface finishing operations in tool production and precision machining. The multi-fluted cross-cut head design delivers consistently smooth surface finishes across metal, alloy, and composite workpieces. Designed for handheld rotary tool applications and CNC spindle mounting, this burr is a stock essential for any shop performing detail work, edge breaking, or form machining. If your facility requires additional size options, consider pairing this with the 4mm variant or exploring the 8mm heavy-duty alternative for larger stock removal tasks.

Key Features

- Multi-Fluted Cross-Cut Design: Star-pattern cutting geometry ensures uniform material removal and prevents chattering

- Smooth Surface Finish: Delivers polished, burr-free results directly from the tool—reducing secondary finishing time

- Carbide Construction: Superior hardness and thermal resistance for extended tool life and consistent performance across extended production runs

- Optimized Geometry: ZYA-S profile balances aggressive cutting with precision control for both manual and automated operations

- Compact 6mm Shank: Compatible with standard S6 rotary tool chucks and CNC spindle collets

Business Advantages

Stock Turnover & Margin: Rotary burrs are consumable-adjacent tools with predictable replacement cycles. High-volume shops replenish regularly, creating steady order frequency and predictable revenue.

Customer Stickiness: Precision finishing tools are often bought in matched sets across multiple profiles and sizes. This 6mm ZYA-S is a natural entry point to building a complete burr inventory with your customers—cross-selling opportunities are substantial.

Competitive Positioning: European-standard carbide burrs command premium pricing in comparison to basic steel alternatives, while remaining cost-effective at scale. Positioning this as "precision grinding without secondary finishing" justifies the price to your end customers.

Low Storage Footprint: Compact dimensions mean high inventory turnover without warehouse strain—ideal for resellers managing limited shelf space.

Technical Specifications

| Specification | Value |

|---|---|

| Cutting Head Diameter (d1) | 6 mm |

| Cutting Head Length (L1) | 16 mm |

| Shank Diameter (d2) | 6 mm |

| Total Length (L2) | 50 mm |

| Shank Type | S6 (Standard 6mm) |

| Profile | ZYA-S (Cross-cut, rounded torpedo) |

| Material | Carbide (hardmetal) |

| Primary Application | Face grinding, deburring, edge breaking, form machining |

| Recommended Speed | 3,000–15,000 RPM (handheld); up to 25,000 RPM (CNC spindle) |

Recommended Use Cases

- Deburring: Removing sharp edges and burrs from machined parts post-production

- Edge Breaking: Precision chamfering on precision-assembly components

- Surface Finishing: Achieving smooth, polished surfaces on cast or forged metal

- Form Machining: Creating precise radii and contours in tool production workflows

- Composite & Soft Metal Work: Ideal for aluminum, brass, and composite materials without excessive chatter

Value to Your Customers

End-users benefit from reduced finishing labor, lower secondary processing costs, and consistent part quality. The smooth surface delivery means fewer rejected parts and faster throughput—metrics that translate directly to your customer's profitability.

Stock this burr in volume for maximum margin and customer satisfaction. Pair with complementary profiles to build complete finishing kits.