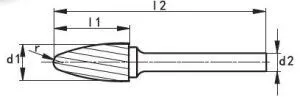

Rotary Burr 6mm Shank, 50mm Length, Cross-Cut Flute Pattern

Precision cross-cut rotary burr for smooth finishing and detailed machining. 6mm shank, tungsten carbide construction.

Request QuoteDescription

Rotary Burr 6mm Shank, 50mm Length, Cross-Cut Flute Pattern

Brief Overview

This 6mm shank rotary burr delivers the smooth surface finishes required for precision tool production and detailed component machining. The cross-cut spiral flute pattern—visible as a diamond lattice across the cutting head—provides controlled material removal with minimal vibration, making it ideal for finishing work and intricate deburring tasks. Whether you stock alternative egg-shaped burr profiles or larger capacity options for extended cutting lengths, this standard 6x50 geometry remains a foundational item in any rotary tool catalog.

Key Features

- Cross-Cut Spiral Flute Design: Diamond-pattern teeth arrangement delivers superior surface finish compared to single-flute designs; reduces chatter and vibration during operation

- Tungsten Carbide Construction: High hardness and thermal stability enable consistent performance across varied materials—steel, aluminum, brass, composites

- Rounded Egg-Shaped Head: Optimized geometry for finishing passes, deburring, and radius work; tapered tip reduces catching and material damage

- 6mm Straight Shank: Compatible with standard rotary tool chucks and flexible shaft adapters; straightforward integration into existing shop workflows

- 50mm Overall Length: Balanced reach-to-stability ratio suitable for both general machining and confined-space finishing

Why Resellers Choose This Burr

Turnover & Margin: Cross-cut burrs occupy a reliable middle position in the rotary tool market—not commodity pricing, but high-volume demand. Mechanics and tool makers request them repeatedly for finishing work.

Customer Loyalty: Precision finishes drive repeat orders. When your customers achieve smooth, burr-free surfaces consistently, they return for the same tool.

Compact Inventory Footprint: A single SKU covers the most common 6mm/50mm finishing requirement. Complement with smaller precision burrs for delicate work and larger versions for heavy stock removal to build a complete range without excess stock.

Low Return Risk: Straightforward design with no moving parts or precision assemblies—durability is predictable, complaints are rare.

Technical Specifications

| Parameter | Value |

|---|---|

| Shank Diameter (d1) | 6 mm |

| Head Diameter (d2) | 6 mm |

| Cutting Head Length (L1) | 18 mm |

| Overall Length (L2) | 50 mm |

| Flute Pattern | Cross-Cut Spiral |

| Material | Tungsten Carbide |

| Shank Type | Straight, 6mm |

| Packaging | Individual (1 per unit) |

| Product Code | A-MD7886650 |

Application Context

This burr excels in tool rooms, precision job shops, and maintenance departments:

- Tool & Die Work: Finishing dies and punch faces; deburring sharp edges post-machining

- Metal Fabrication: Smoothing weld seams, blending transitions, radius work on structural components

- Automotive Repair: Precision finishing in confined engine bays; deburring valve seats and orifice work

- General Machining: Surface preparation before plating or coating; finishing internal cavities and contours

The cross-cut pattern ensures a refined surface without requiring secondary polishing—a time-saver that justifies the tool's place in every professional kit.

Stock & Order Recommendation

Standard pack size: 1 unit per box. Recommend minimum order of 10–25 units to support small-to-medium shop turnover. Pair with complementary sizes (4mm shank variants and 8mm options) to offer resellers a complete finishing solution and increase basket value.