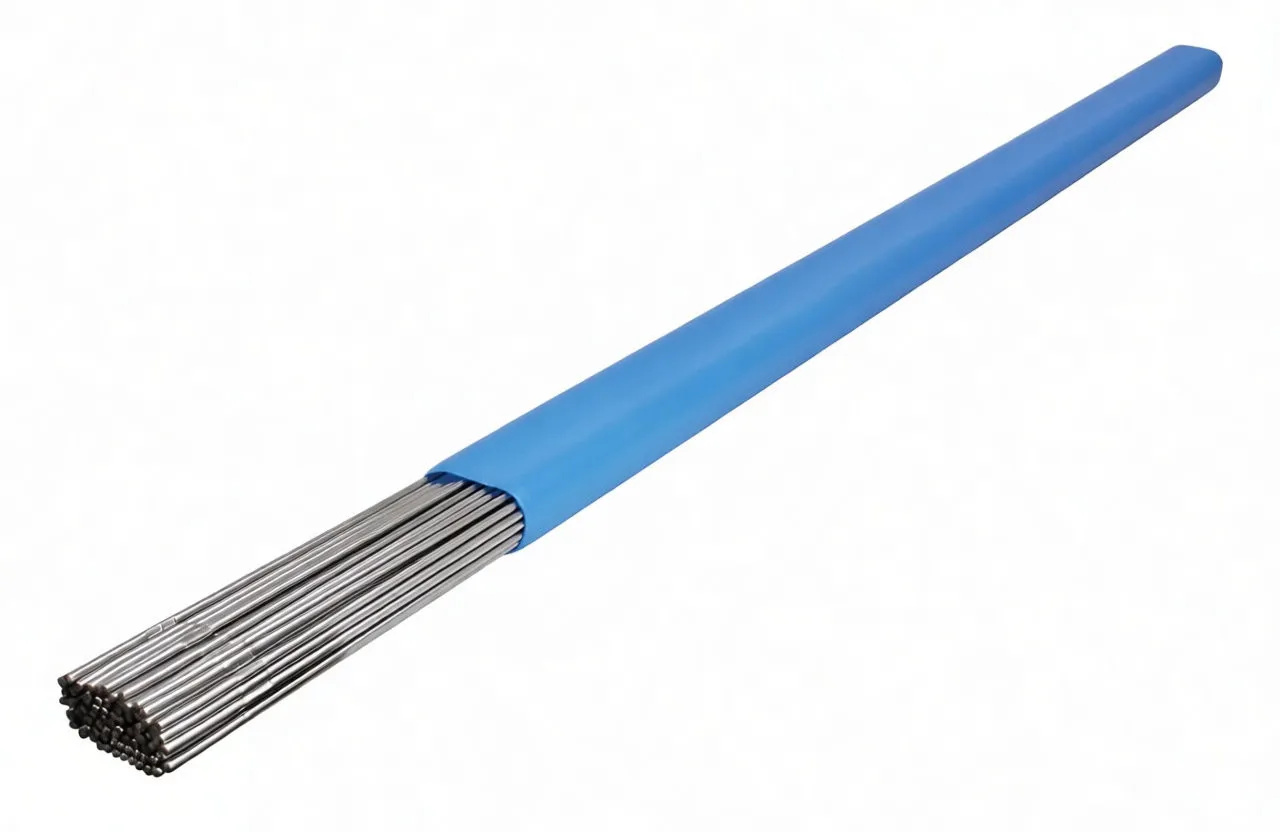

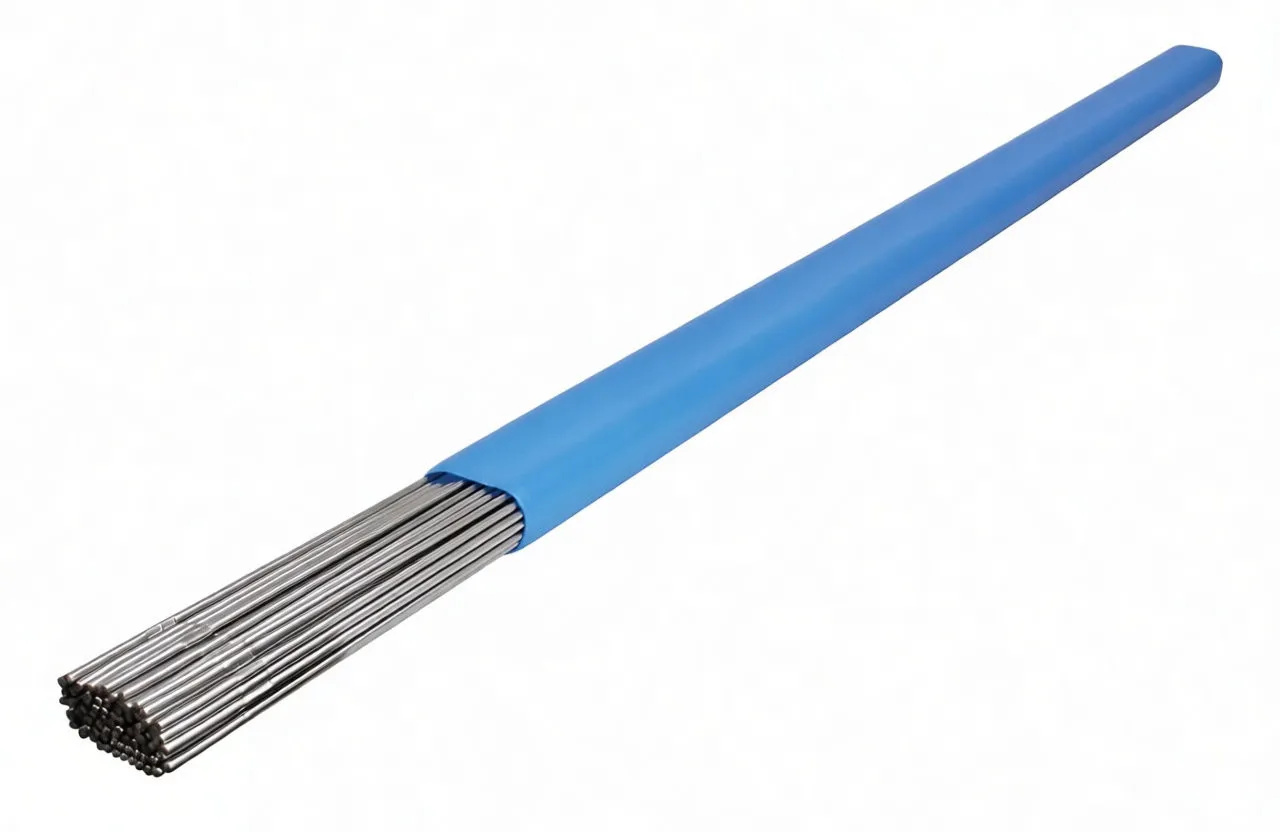

TIG Rod ER316L Stainless Steel, 1.0mm Diameter, 1 Meter Length

Premium ER316L TIG filler rod for corrosion-resistant welding of stainless steel equipment in chemical and petrochemical applications.

Request QuoteDescription

TIG Rod ER316L Stainless Steel – Premium Corrosion-Resistant Filler Rod

Overview

This ER316L TIG filler rod is engineered for all-position welding of austenitic stainless steel components in demanding industrial environments. The molybdenum content (2.59%) delivers superior corrosion resistance against acetic acid, sulfurous acid, phosphoric acid, and salt exposure—making it ideal for petrochemical and fertilizer equipment fabrication. If your shop also handles aluminium or lower-alloy stainless applications, consider complementary aluminium TIG filler rods or 308LSi stainless alternatives to expand your consumable inventory.

Key Features

- All-Position Capability: Smooth, consistent bead formation without positional limitations

- Low Spatter Profile: Minimizes post-weld cleanup and improves operator efficiency

- Molybdenum-Enhanced Chemistry: C-12Ni-2Mo composition provides excellent resistance to aggressive chemical environments

- Premium Surface Finish: Polished, uniform rod diameter ensures reliable wire feeding and arc stability

- Protective Packaging: Sealed blue sleeve maintains rod integrity and prevents oxidation during storage

- International Certification: Complies with AWS A5.9, BS EN ISO 14343, JIS Z3321, and GB 4241/2 standards

Business Advantages for Resellers

- Recurring Revenue Stream: Consumable product with predictable reorder cycles from fabrication shops

- High-Margin Category: Filler metals command strong profit margins in industrial distribution

- Customer Lock-In: Shops using specific alloy grades (316L for corrosive environments) return consistently

- Cross-Sell Potential: Position alongside complementary stainless TIG rods and welding equipment supplies

- Essential for Specialized Applications: Petrochemical and fertilizer sectors demand certified 316L—non-substitutable in many contracts

Technical Specifications

| Parameter | Specification |

|---|---|

| Diameter | 1.0 mm |

| Length | 1 meter |

| Weight per Pack | 5 kg |

| Packaging Dimensions | 13.5 cm (L) × 2.5 cm (W) |

| AWS Classification | AWS A5.9 ER316L |

| European Standard | BS EN ISO 14343-B-SS316L |

| Japanese Standard | JIS Z3321 Y316L |

| German/Chinese Standard | GB 4241/2 H03Cr19Ni12Mo2Si |

Chemical Composition (%)

| Element | Content |

|---|---|

| Carbon (C) | 0.023 |

| Manganese (Mn) | 1.90 |

| Silicon (Si) | 0.42 |

| Chromium (Cr) | 19.12 |

| Nickel (Ni) | 12.59 |

| Molybdenum (Mo) | 2.59 |

| Phosphorus (P) | 0.009 |

| Sulfur (S) | 0.008 |

Recommended Applications

- Petrochemical Equipment: Welding of pressure vessels, heat exchangers, and piping subject to corrosive fluid exposure

- Fertilizer Manufacturing: Joining of stainless steel components in acid-handling equipment

- Material Compatibility: Designed for welding 022Cr17Ni12Mo2 (SUS 316L) and equivalent austenitic stainless steels

- Chemical Processing: Applications requiring resistance to sulfurous acid, phosphoric acid, and salt-laden environments

Why Resellers Choose This Product

At 1.0mm diameter and 5kg per pack, this rod offers a practical balance between precision welding (for detailed fabrication work) and production efficiency. The molybdenum-enhanced alloy eliminates the need to source multiple consumables for corrosion-critical jobs—one certified product serves the entire 316L welding portfolio. Stock this rod and position yourself as a trusted supplier to shops handling chemical and petrochemical fabrication.

Ready to stock premium stainless TIG filler rods? Order in bulk to secure margin and meet the consistent demand from your industrial customer base.