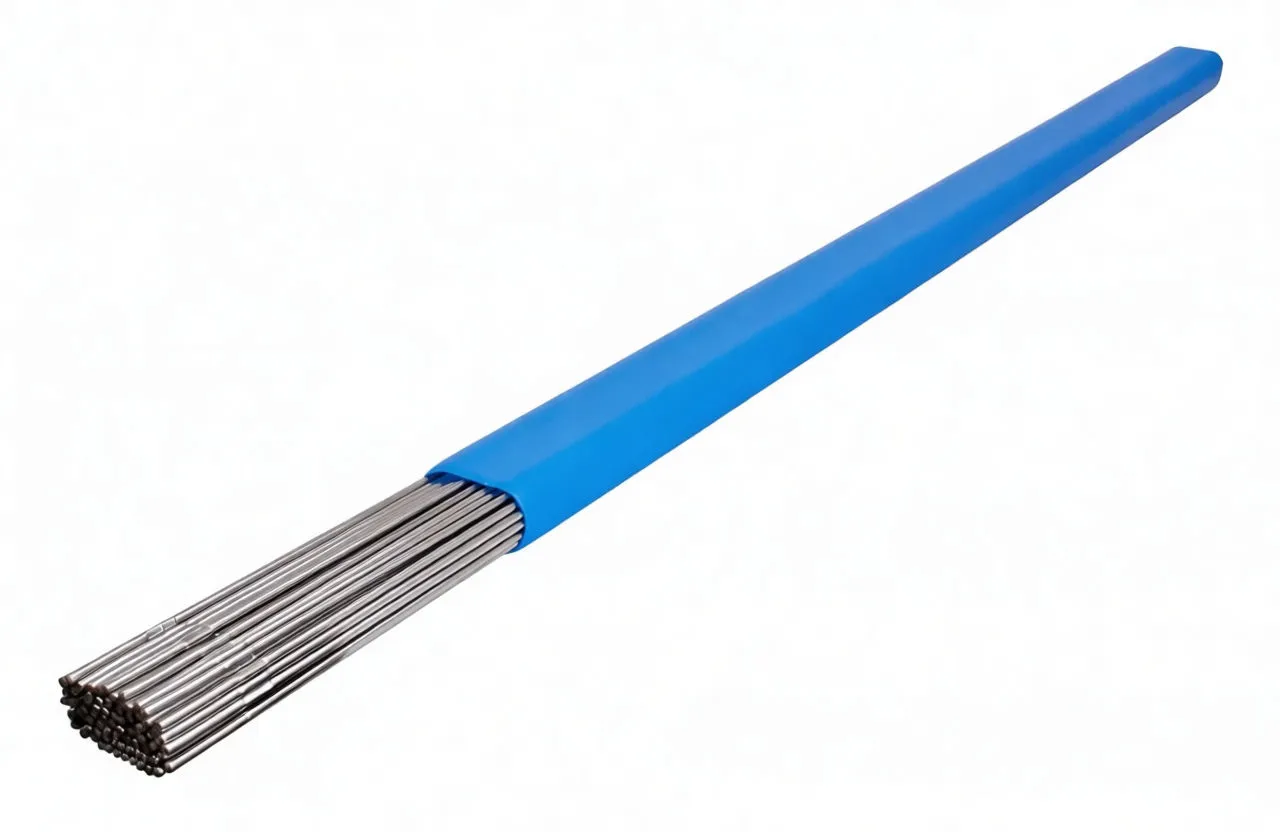

TIG Rod ER316L Stainless Steel, 1.6mm Diameter, 1M Length

Premium ER316L TIG welding rod for petrochemical and corrosion-resistant applications. AWS A5.9 certified, 1.6mm x 1M bundle.

Request QuoteDescription

TIG Rod ER316L Stainless Steel – Premium Grade Welding Consumable

Brief Overview

This ER316L TIG welding rod is a high-performance, all-position stainless steel consumable engineered for critical industrial applications where corrosion resistance and weld integrity are non-negotiable. Formulated to AWS A5.9 specifications, it delivers consistent arc characteristics, minimal spatter, and superior bead aesthetics across petrochemical, fertilizer, and pressure vessel manufacturing.

For operations requiring broader material compatibility, consider pairing this with alternative stainless variants like ER308LSi for applications demanding enhanced silicon content, or standard carbon steel options for non-corrosive environments.

Key Technical Features

- AWS Classification: A5.9 ER316L

- International Standards: BS EN ISO 14343-B-SS316L, JIS Z3321 Y316L, GB 4241/2 H03Cr19Ni12Mo2Si

- Alloy Composition: C-12Ni-2Mo (molybdenum-enhanced stainless steel)

- Position Capability: All-position welding (flat, horizontal, vertical, overhead)

- Arc Performance: Smooth, stable arc with excellent fusion characteristics and low spatter generation

- Bead Quality: Smooth, visually refined welds with minimal post-weld cleaning required

Chemical Composition (Typical %)

| Element | Content |

|---|---|

| Carbon (C) | 0.023 |

| Manganese (Mn) | 1.90 |

| Silicon (Si) | 0.42 |

| Chromium (Cr) | 19.12 |

| Nickel (Ni) | 12.59 |

| Molybdenum (Mo) | 2.59 |

| Phosphorus (P) | 0.009 |

| Sulfur (S) | 0.008 |

Corrosion Resistance & Material Compatibility

The molybdenum addition (2.59%) provides exceptional resistance to:

- Acetic acid environments (food processing, chemical storage)

- Sulfurous acid (industrial gas processing)

- Phosphoric acid (fertilizer and chemical manufacturing)

- Chloride-bearing salts (marine and coastal applications)

- Pitting and crevice corrosion in aggressive industrial atmospheres

Primary Application Base: ER316L is purpose-designed to weld 022Cr17Ni12Mo2 (SUS 316L) stainless steel and equivalent duplex/super-austenitic alloys without embrittlement or loss of ductility in the heat-affected zone.

Product Specification

| Parameter | Value |

|---|---|

| Rod Diameter | 1.6 mm |

| Rod Length | 1.0 M |

| Bundle Weight | 5 kg |

| Bundle Dimensions (L × W) | 13.5 cm × 2.5 cm |

| Packaging | Protective blue sleeve with identification label |

Business Advantages for Distributors

- High Margin Potential: Specialized stainless consumables command premium pricing while maintaining strong customer demand in industrial sectors

- Essential for Critical Applications: Petrochemical and fertilizer operations cannot compromise on corrosion resistance—lock in recurring orders

- Standardized Specifications: AWS/EN/JIS/GB certifications ensure acceptance across global supply chains and major OEM specifications

- Predictable Consumption: TIG welding generates predictable rod burn rates—enables accurate forecasting and scheduled replenishment programs

- Minimal Returns: Superior bead quality and low spatter reduce customer complaints and rework costs, strengthening your reputation

- Bulk Order Efficiency: 5 kg bundles are production-friendly; customers typically order in cases (4–12 bundles) for monthly consumption

Reseller Positioning

Position this rod to your customers as the reliability standard for critical stainless welding work. Emphasize:

- Proven AWS compliance eliminates qualification risk

- Molybdenum chemistry prevents unexpected corrosion failures

- Low spatter = faster cleanup, reduced labor costs, higher shop throughput

- Smooth bead profile reduces cosmetic rework on visible assemblies

Volume Incentive: Offer case pricing (4+ bundles) to incentivize larger orders and improve your inventory turn.

Call to Action

Stock this ER316L rod as a core consumable in your stainless welding lineup. Its combination of technical performance, global standardization, and critical-application demand makes it a reliable profit center. Contact our team for bulk pricing and scheduled delivery arrangements.