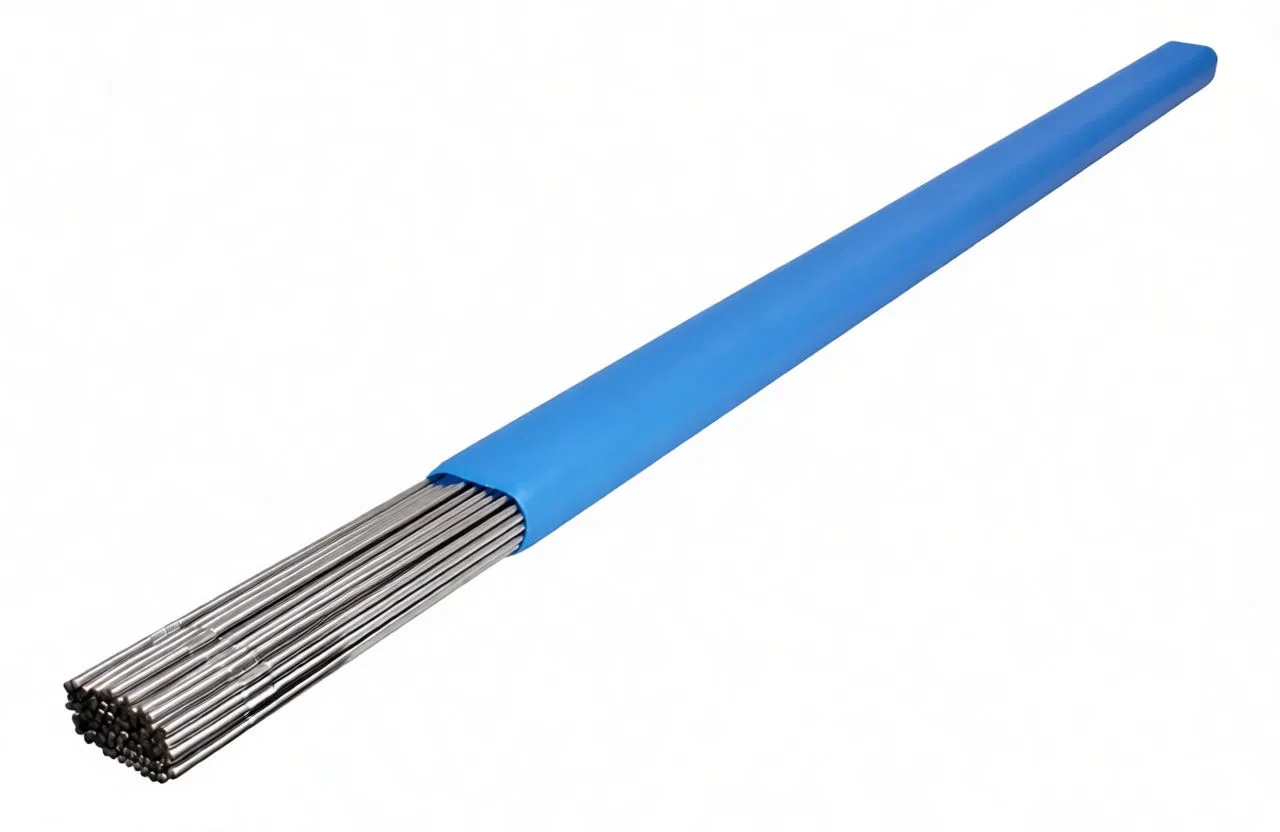

TIG Rod ER316L Stainless Steel, 3.2mm Diameter, 1 Meter Length

Molybdenum-enhanced ER316L TIG filler rod for corrosion-resistant welding of austenitic stainless steel in petrochemical and chemical applications.

Request QuoteDescription

TIG Rod ER316L Stainless Steel, 3.2mm Diameter, 1 Meter Length

Brief Overview

This ER316L stainless steel TIG filler rod is engineered for all-position welding of austenitic stainless steels, particularly SUS 316L materials used in petrochemical and chemical equipment manufacturing. The molybdenum content (2.59%) provides superior corrosion resistance to acetic acid, sulfurous acid, phosphoric acid, and salt environments—critical for industries where chemical attack is a constant concern. Stock this alongside compatible ER308LSi stainless rods and aluminum TIG consumables to offer customers a complete TIG welding portfolio.

Key Features

- Molybdenum-Enhanced Composition: 19.12% Chromium, 12.59% Nickel, 2.59% Molybdenum ensures excellent corrosion resistance in aggressive chemical environments

- All-Position Capability: Smooth, spatter-free welds with consistent bead appearance regardless of joint orientation

- Low Carbon Content: 0.023% carbon minimizes sensitization and intergranular corrosion in the heat-affected zone

- Clean Metallurgy: Tight control on phosphorus (0.009%) and sulfur (0.008%) prevents brittleness and improves ductility

- Uniform Diameter: 3.2mm consistent cross-section ensures predictable wire feed and arc stability

- 1 Meter Convenient Length: Compact form factor reduces waste and simplifies storage; 5kg bundle optimizes handling and inventory rotation

Technical Specifications

| Parameter | Value |

|---|---|

| Wire Diameter | 3.2mm |

| Length per Rod | 1 meter |

| Package Weight | 5kg |

| Chromium Content | 19.12% |

| Nickel Content | 12.59% |

| Molybdenum Content | 2.59% |

| Carbon Content | 0.023% |

| Manganese | 1.90% |

| Silicon | 0.42% |

| AWS Classification | A5.9 ER316L |

| EN ISO Classification | BS EN ISO 14343-B-SS316L |

| JIS Classification | Z3321 Y316L |

| GB Classification | 4241/2 H03Cr19Ni12Mo2Si |

| Primary Applications | Petrochemical equipment, fertilizer plant fabrication, chemical vessels |

| Corrosion Resistance | Acetic acid, sulfurous acid, phosphoric acid, salt environments |

Business Advantages for Resellers

- High Margin Consumable: TIG filler rods are regular replenishment items with steady demand in fabrication shops and maintenance operations

- Petrochemical & Chemical Market Leverage: Industries requiring 316L stainless (petrochemical, pharmaceutical, food processing) operate on strict material specifications—no substitutions, reliable repeat orders

- Compact Packaging: 5kg bundles appeal to small-to-medium job shops while supporting larger fabricators' inventory management

- Quality Certification: AWS/ISO/JIS classification simplifies customer compliance documentation and material traceability

- Bundling Opportunity: Pair with complementary stainless rods or mild steel MIG consumables to increase average transaction value

Application Notes

Ideal For:

- Welding of 022Cr17Ni12Mo2 (SUS 316L) plate and pipe

- All-position TIG welding in chemical and petrochemical fabrication

- Equipment exposed to corrosive media requiring superior chemical resistance

- Maintenance and repair welding where material matching is mandatory

Performance Characteristics:

- Excellent weldability across all positions (flat, vertical, overhead)

- Minimal spatter—reduces cleanup time and material loss

- Smooth bead profile—improves appearance and reduces post-weld finishing

- Superior pitting resistance due to molybdenum content—outperforms 304L/308L in acidic and chloride-rich environments

Close

For fabricators and maintenance departments working in chemical processing, petrochemical refining, or pharmaceutical manufacturing, ER316L is non-negotiable. This 3.2mm rod delivers the exact material properties your customers need—backed by full AWS/ISO certification. Stock depth, reliable supply, and straightforward resale positioning make this a cornerstone consumable for any welding distributor serving industrial markets.