Mercedes Timing Chain Tool Set – Separating, Riveting & Alignment Tool Kit

Professional timing chain service set for Mercedes petrol and diesel engines with separating, riveting, and alignment tools for efficient chain repair and installation.

Request QuoteDescription

Mercedes Timing Chain Tool Set – Separating, Riveting & Alignment Tool Kit

Brief Overview

This timing chain tool set is purpose-built for Mercedes petrol and diesel engine service, combining essential separation, riveting, and alignment functionality in a single, organized carrying case. The set enables technicians to quickly disassemble, inspect, repair, and reassemble timing chains with precision—critical work that demands accuracy and the right equipment. Whether you're stocking a shop or expanding your timing service capabilities, this set delivers the core tools needed for reliable timing chain work on a broad range of Mercedes applications. Consider pairing this with engine timing alignment tools for BMW and Citroën models to broaden your multi-brand service capacity.

Key Features & Components

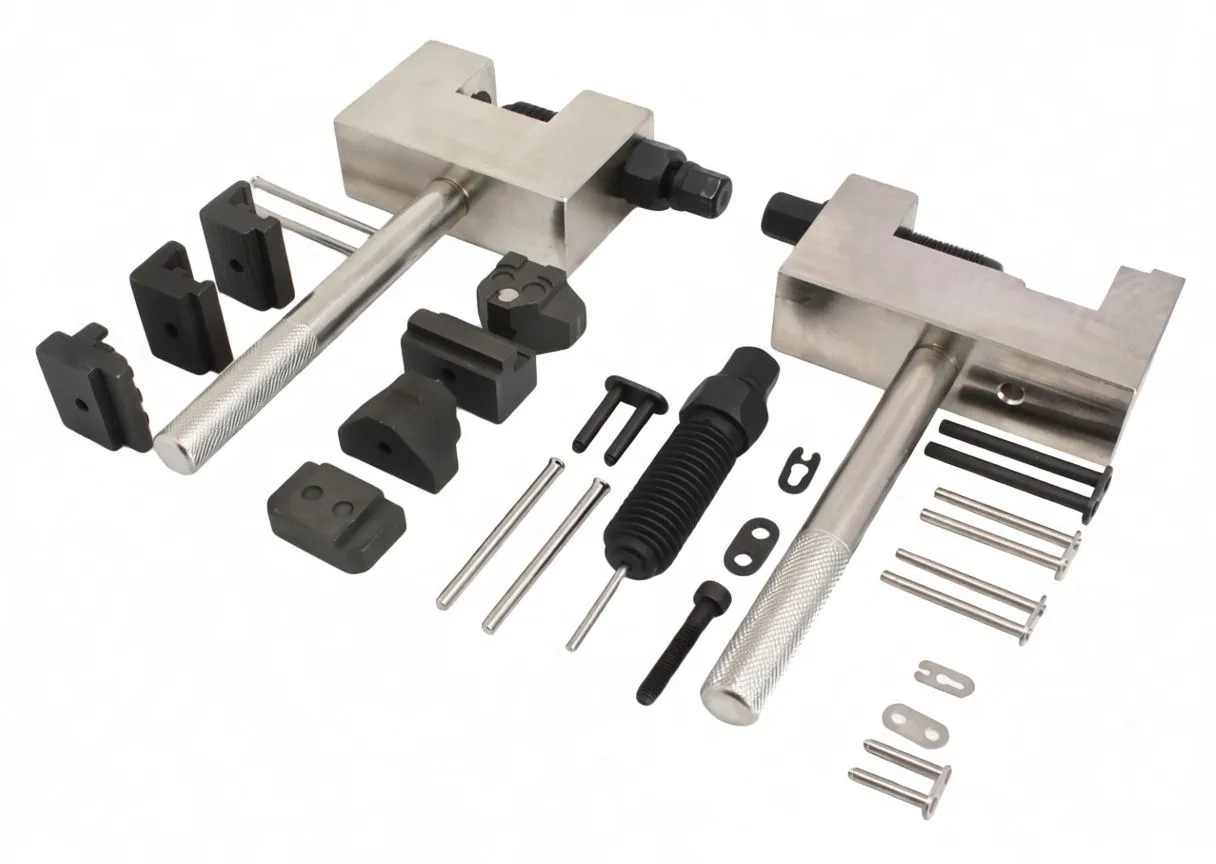

- Dual Heavy-Duty Clamp Blocks: Two stainless steel L/C-shaped clamp assemblies with threaded adjustment bolts and knurled steel handles for secure, precise positioning of timing chain components

- Clipping Punch Set: Two precision-formed punches (Ø 4mm × 50mm) for controlled chain link separation and clip removal

- Riveting Tool: Dedicated riveting mechanism for accurate chain link reassembly and permanent fastening

- Comprehensive Adapter Set: Multiple shaped black adapter blocks and spacer blocks (including 8mm variants) for alignment and positioning across different engine configurations

- Precision Alignment Hardware: Steel alignment pins, U-shaped retaining clips, and mounting plates for exact component positioning during service

- Protective Components: Rubber boot and protective fixtures to prevent damage to delicate timing chain surfaces

- Professional Carrying Case: Blue molded plastic case with organized tray layout, lid-mounted instruction labels, and secure metal latches for safe transport and storage

Engine Compatibility

Primary Applications:

- Mercedes-Benz 615, 616, 617 (classic diesel engines)

- M102, M103, M116 (petrol engines)

- Mercedes 207 (1.7D, 2.1D, 2.2D diesel variants)

- Mercedes diesel engines: 2.7D, 3.0D, 3.2D, 3.9D, 4.0D CDI

Secondary/Extended Compatibility:

- Selected SAAB models (2.2D, 2.7D diesel)

- BMW diesel variants (2.2D, 2.7D)

- Chrysler/Jeep 2.2D, 2.7D diesel

- Diesel 3.0D CRD engines

Business Advantages for Resellers

- Multi-Engine Compatibility: Primary focus on Mercedes with proven cross-compatibility on SAAB, BMW, and Chrysler/Jeep diesel models expands your addressable customer base without purchasing separate kits

- Complete Service Solution: Eliminates the need to source separating, riveting, and alignment tools individually—reduces inventory complexity and improves shop margins on timing chain jobs

- Professional Presentation: Organized carrying case with clear component layout enhances customer confidence and justifies premium labor rates for precision timing work

- High-Margin Service Work: Timing chain service is labor-intensive; equipping your resellers with the right tools increases their capacity and profitability

- Durable Investment: Stainless steel and precision-machined components withstand repeated use, ensuring long equipment lifespan and consistent resale value

Technical Specifications

| Specification | Details |

|---|---|

| Primary Application | Mercedes petrol and diesel engine timing chain service |

| Engine Models Supported | M102, M103, M116, 615, 616, 617, 207, 3.0D CDI, 4.0D CDI, and others (see compatibility list) |

| Tool Types Included | Separating tool, clipping punch set (2 × Ø 4mm × 50mm), riveting tool, adapter blocks, alignment pins, retaining clips |

| Clamp Material | Stainless steel with brushed finish |

| Clamp Features | Threaded adjustment bolts, knurled steel handles |

| Adapter Block Material | Molded/forged black composite; includes 8mm variants |

| Carrying Case | Blue molded plastic with organized tray, metal latches, instruction label |

| Condition | Professional-grade, ready-to-use set |

Application Context

Timing chain service is one of the most demanding precision jobs in diesel and petrol engine rebuilds. Improper separation can damage irreplaceable chain links; incorrect riveting creates catastrophic timing failures. This set eliminates guesswork by providing purpose-designed tools for each step of the process:

- Separation: Clean, controlled removal of worn or damaged chain links

- Riveting: Precise reassembly ensuring proper chain tension and synchronization

- Alignment: Clamps and pins hold components in exact position during service, preventing costly rework

For shops servicing Mercedes diesel engines (especially 2.2D–3.0D models), this tool set is not optional—it's essential infrastructure for reliable, profitable timing work.

Call to Value

Stock this set to position your shop as a Mercedes diesel specialist. The combination of separation, riveting, and alignment tools in one case eliminates multiple tool purchases and setup time. For distributors, this is a high-value SKU that appeals to independent mechanics, small fleets, and rebuild shops—all willing to invest in proven timing service equipment.

Recommended for resellers targeting diesel mechanics and engine rebuild specialists across European and North American markets.